Preparation method for B4C-HfB2 high-temperature eutectic in-situ composite ceramic

A composite ceramic, b4c-hfb2 technology, applied in the field of B4C-HfB2 binary eutectic self-generated composite ceramics and its preparation, can solve the problems of high sintering temperature, long preparation cycle, etc., achieve uniform structure, short preparation cycle, eutectic small tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This implementation case is a B 4 C-HfB 2 A method for preparing high-temperature eutectic self-generated composite ceramics.

[0029] The method is: using commercially available high-purity B 4 C and HfB 2 Powder, in molar ratio, where B 4 The molar content of C powder is 50%, HfB 2 The molar content of zirconia balls is 50%, using a polyethylene ball mill tank, and the zirconia balls are ball-milled at a speed of 300 rpm on a high-energy ball mill for 1 hour to obtain the required powder, and then the ball-milled powder is cooled at room temperature Isostatic pressing into a sheet with a diameter of 10mm and a height of about 5mm, put it into an arc melting furnace, and in an argon environment of 60kPa, the sample is rapidly melted by arc discharge, the output power is 20-40%, and the current It is 120-250A, and then the copper plate in the electric arc melting furnace is rapidly cooled to room temperature, and the water pressure is 0.06-0.07MPa.

[0030] tested...

Embodiment 2

[0032] This implementation case is a B 4 C-HfB 2 A method for preparing high-temperature eutectic self-generated composite ceramics.

[0033] The method is: using commercially available high-purity B 4 C and HfB 2 Powder, in molar ratio, where B 4 The molar content of C powder is 65%, HfB 2 The molar content is 35%, using polyethylene ball milling tank, zirconia balls are milled on a high-energy ball mill at a speed of 300 rpm for 1 hour to obtain the required powder, and then the powder after ball milling is uniformly cooled at room temperature Isostatic pressing into a sheet with a diameter of 10mm and a height of about 5mm, put it into an arc melting furnace, and in an argon environment of 60kPa, the sample is rapidly melted by arc discharge, the output power is 20-40%, and the current It is 120-250A, and then the copper plate in the electric arc melting furnace is rapidly cooled to room temperature, and the water pressure is 0.06-0.07MPa.

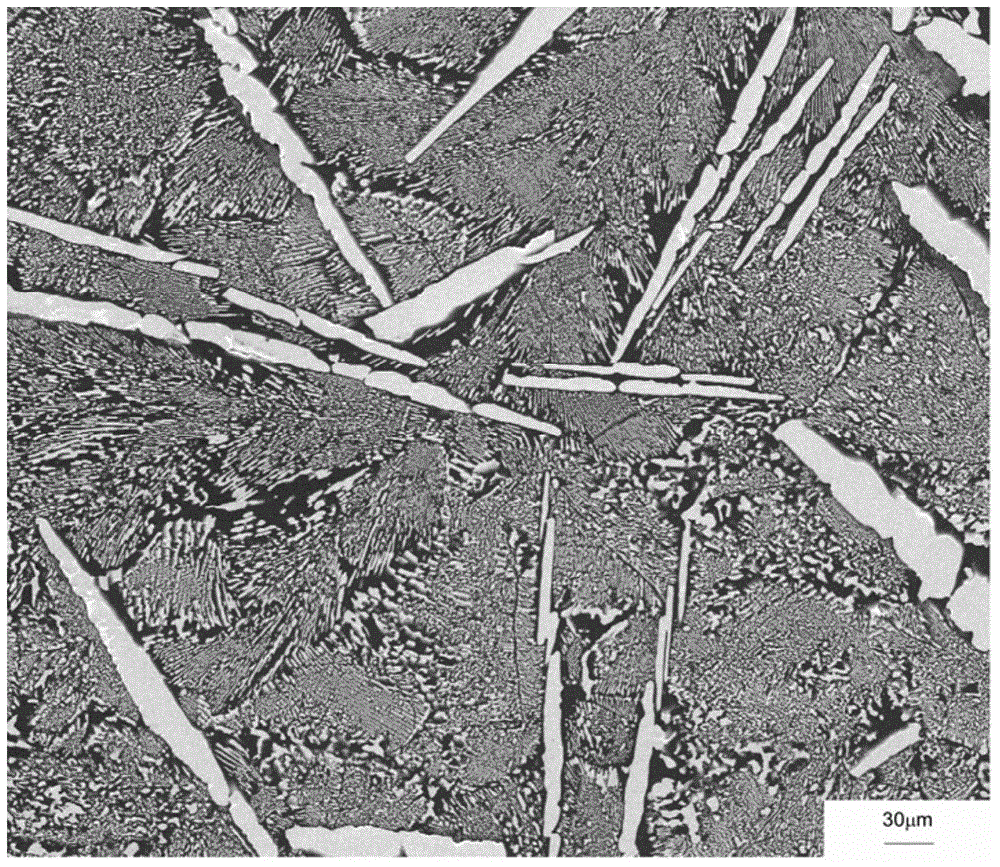

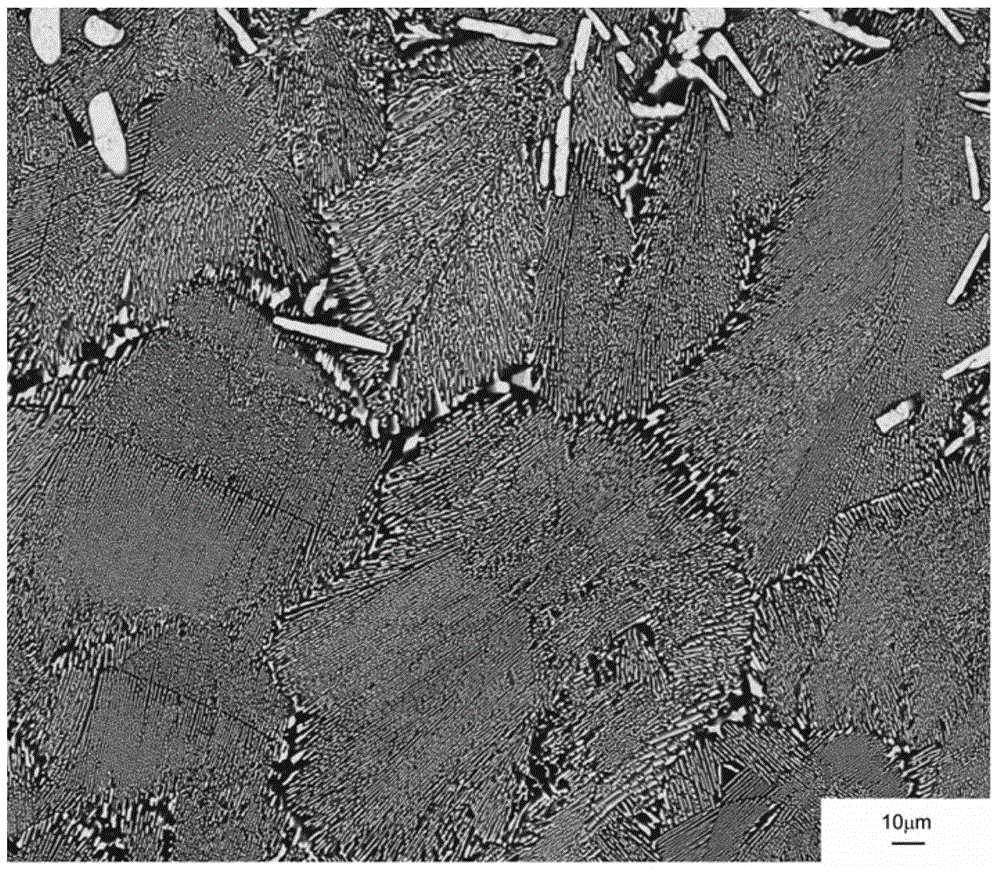

[0034] tested, see figure...

Embodiment 3

[0036] This embodiment is a B 4 C-HfB 2 A method for preparing high-temperature eutectic self-generated composite ceramics.

[0037] The method is: using commercially available high-purity B 4 C and HfB 2 Powder, in molar ratio, where B 4 The molar content of C powder is 78%, HfB 2 The molar content is 22%. A polyethylene ball mill tank is used. The zirconia balls are milled on a high-energy ball mill at a speed of 300 rpm for 1 hour to obtain the required powder. Isostatic pressing into a sheet with a diameter of 10mm and a height of about 5mm, put it into an arc melting furnace, and in an argon environment of 60kPa, the sample is rapidly melted by arc discharge, the output power is 20-40%, and the current It is 120-250A, and then the copper plate in the electric arc melting furnace is rapidly cooled to room temperature, and the water pressure is 0.06-0.07MPa.

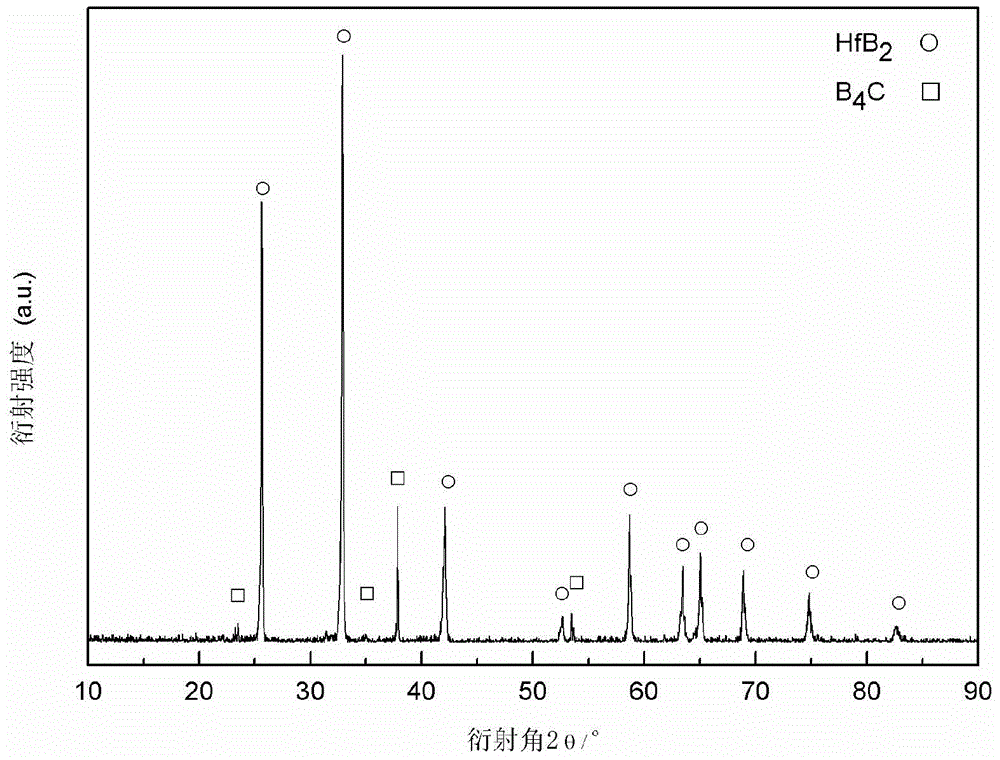

[0038] tested, see figure 1 and Figure 4 , the B 4 C-HfB 2 The XRD patterns of high-temperature eutectic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com