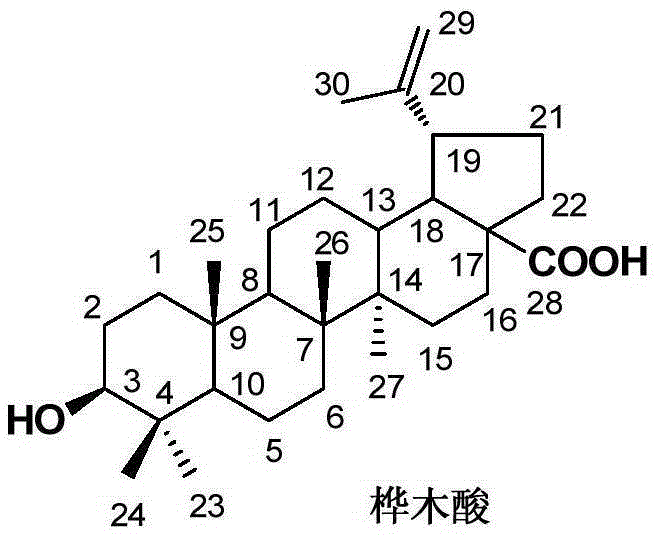

Method for extracting and separating betulinic acid from water chestnut skin

A technology of water chestnut bark and betulinic acid, applied in the directions of steroids, organic chemistry, etc., can solve unseen problems and achieve the effects of low production cost, high product purity and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) In the extraction tank, add 800g of water chestnut skin powder and 8.0L of 70% by volume methanol aqueous solution, extract at 70°C for 2 hours, filter, and extract 3 times in total, combine the filtrates, concentrate under reduced pressure into a paste, and obtain the extract 138g.

[0022] (2) Add 800 mL of water to the extract to make a turbid liquid, then add 1.6 L of ethyl acetate to extract 3 times, combine the extracts, concentrate under reduced pressure, and obtain 11.5 g of the extract.

[0023] (3) Add 30mL of methanol to the extract until completely dissolved, add 30g of silica gel to mix the sample, separate by silica gel column chromatography, elute with petroleum ether-ethyl acetate solution with a volume ratio of 8:2, detect by thin layer chromatography, and collect The eluents containing betulinic acid were combined and concentrated under reduced pressure to obtain 1.82 g of crude product.

[0024] (4) Dissolve the crude product in 10 mL of hot etha...

Embodiment 2

[0026] (1) In the extraction tank, add 800g of chestnut skin powder and 6.4L of 90% ethanol aqueous solution by volume, extract at 80°C for 2.5 hours, filter, and extract 3 times in total, combine the filtrates, concentrate the paste under reduced pressure, and obtain the extract 115g.

[0027] (2) Add 1.0 L of water to the extract to make a turbid liquid, add 2.0 L of ethyl acetate to extract 3 times, combine the extracts, concentrate under reduced pressure, and obtain 10.3 g of the extract.

[0028] (3) Add 30mL of methanol to the extract until completely dissolved, add 30g of silica gel to mix the sample, separate by silica gel column chromatography, elute with petroleum ether-ethyl acetate solution with a volume ratio of 8.5:1.5, detect by thin layer chromatography, and collect The eluents containing betulinic acid were combined and concentrated under reduced pressure to obtain 1.76 g of crude product.

[0029] (4) Dissolve the semi-finished product in 10 mL of hot ethano...

Embodiment 3

[0031] (1) In the extraction tank, add 800g of water chestnut skin powder and 6.4L of 70% by volume acetone aqueous solution, extract at 50°C for 2 hours, filter, extract 3 times in total, combine the filtrates, concentrate under reduced pressure into a paste, and obtain the extract 115g.

[0032] (2) Add 800 mL of water to the extract to make a turbid liquid, then add 1.6 L of ethyl acetate to extract 3 times, combine the extracts, concentrate under reduced pressure, and obtain 12.2 g of the extract.

[0033] (3) Add 30mL of methanol to the extract until completely dissolved, add 30g of silica gel to mix the sample, separate by silica gel column chromatography, elute with petroleum ether-ethyl acetate solution with a volume ratio of 9:1, detect by thin layer chromatography, and collect The eluents containing betulinic acid were combined and concentrated under reduced pressure to obtain 2.77 g of crude product.

[0034] (4) Dissolve the semi-finished product in 10mL of hot me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com