Catalyst for polydiene synthesis and preparation method thereof

A polydiene and catalyst technology, which is applied in the field of polydiene synthesis catalyst and its preparation, can solve the problems of unfavorable application, difficult control of catalyst form and catalyst particle size, limited reaction temperature and the like, and achieves low crystallinity, The effect of good fluidity and high trans content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Correspondingly, the application provides a method for preparing a catalyst for polydiene synthesis, comprising the following steps:

[0059] 1) The spherical carrier reacts with the active component, and the main catalyst precursor is obtained after heating up; the spherical carrier is magnesium chloride alcoholate or spherical silica, and the active component is titanium halide, vanadium one or more of halides, titanium oxyhalides and vanadium oxyhalides;

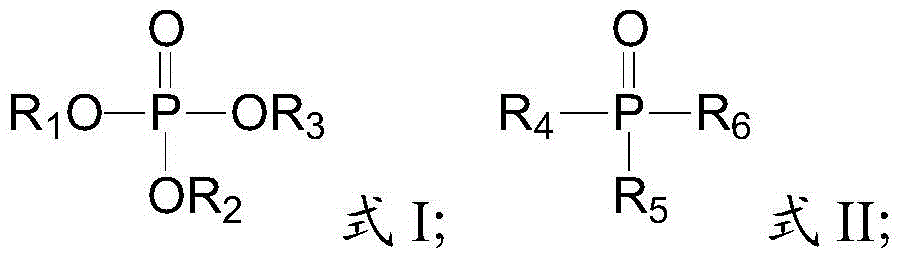

[0060] 2) reacting the procatalyst precursor with a phosphate compound, and continuing to heat up to obtain a procatalyst; the procatalyst includes a spherical carrier, an active component loaded on the spherical carrier, and a phosphate compound;

[0061] 3) The main catalyst and the co-catalyst are added to the polymerization system to catalyze the polymerization of the diene during the synthesis process of the polydiene.

[0062] This application improves the preparation process of the catalyst, uses spherical ...

Embodiment 1

[0079] (1) carrier preparation

[0080] In a 250mL glass reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer, and fully replaced with nitrogen, add 36.5mL of absolute ethanol and 21.3g of anhydrous magnesium chloride (ratio of magnesium alcohol to 2.8:1), and stir After the magnesium chloride is completely dissolved, add 75mL of white oil and 75mL of silicone oil, stir and mix, and maintain at 120°C for 1 hour to obtain a uniformly dispersed emulsion;

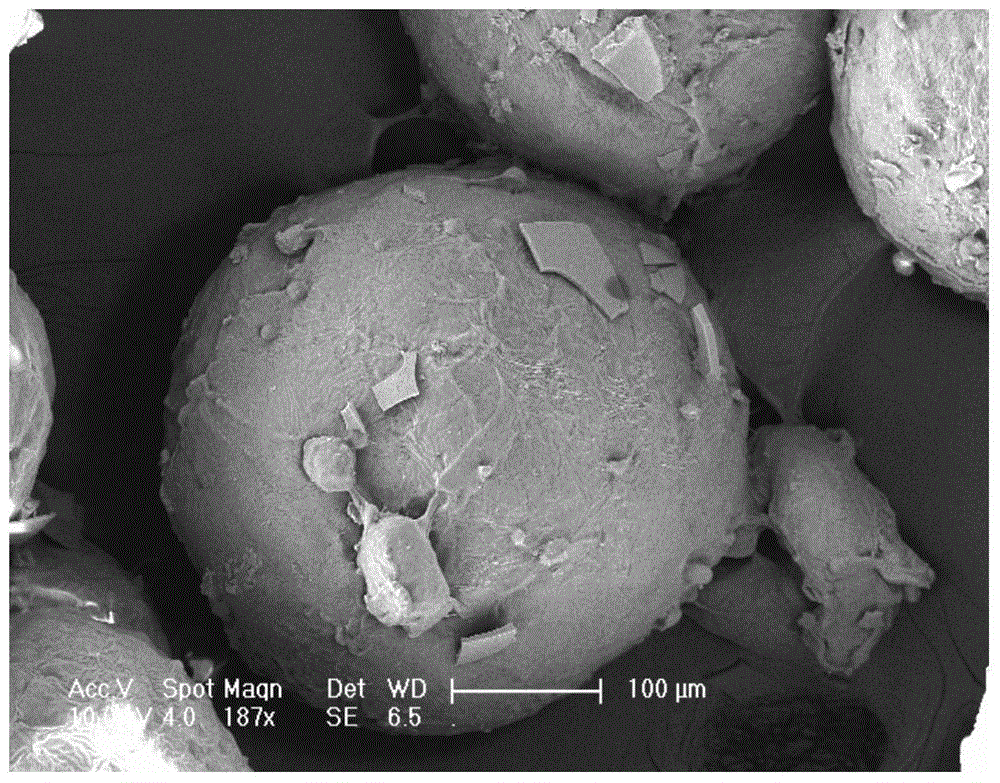

[0081] Through the emulsifier, under the condition of pressure of 0.3MPa and emulsifier speed of 3000r / min, the obtained emulsion is sprayed into another stirred reactor containing 1600mL of hexane and cooled to -25°C in advance , keep the temperature of hexane not higher than -10°C, stir for 30 minutes, filter, wash with dry hexane, wash away the silicone oil and white oil, vacuum dry and sieve, and obtain a spherical carrier of 30 μm to 50 μm, its composition MgCl 2 2.38C 2 h 6 O.

[0082] (2...

Embodiment 2

[0088] (1) carrier preparation

[0089] In a 250mL glass reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer, and fully replaced with nitrogen, add 36.5mL of absolute ethanol and 21.3g of anhydrous magnesium chloride (ratio of magnesium alcohol to 2.8:1), and stir After the magnesium chloride is completely dissolved, add 75mL of white oil and 75mL of silicone oil, stir and mix, and maintain at a temperature of 120°C for 1.5h to obtain a uniformly dispersed emulsion;

[0090] Through the emulsifier, under the condition of pressure of 0.5MPa and emulsifier speed of 3300r / min, spray the obtained emulsion into another stirred reactor containing 1600mL of hexane and cooled to -25°C in advance , keep the temperature of hexane not higher than -20°C, stir for 30 minutes, filter, wash with dry hexane, wash away the silicone oil and white oil, vacuum dry and sieve to obtain a spherical carrier with a size of 22 μm to 45 μm, its composition MgCl 2 2.54C 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com