Dye composition and preparation method thereof, colorant, photosensitive resin composition and optical filter

A technology of dye compounds and photosensitive resins, applied in the fields of optical filters, chemical instruments and methods, organic dyes, etc., can solve the problems of low transmittance of optical filters, and achieve the effect of reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

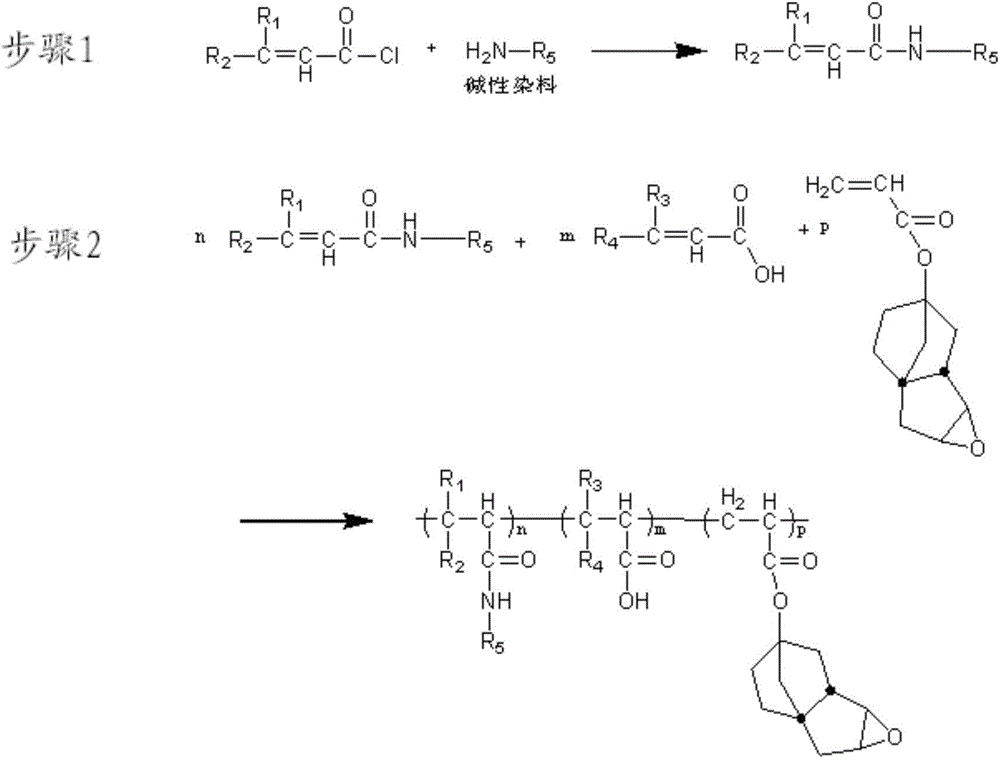

[0056] The present invention also provides a kind of preparation method of above-mentioned dye compound, comprises the following steps (specifically see figure 1 ):

[0057] 1) Preparation of amide compound step

[0058] Amide compounds obtained by reacting ethylenically unsaturated monomers containing acid chlorides with basic dyes containing amino groups;

[0059] Such basic dyes containing amino groups are connected with ethylenically unsaturated double bonds to form polymer compounds.

[0060] 2) Copolymerization step

[0061] Copolymerizing the obtained amide compound with the ethylenically unsaturated monomer containing epoxy functional group and ethylenically unsaturated monomer containing at least one carboxyl group or carboxylic acid anhydride group in a solvent to generate a dye compound.

[0062]Wherein, the ethylenically unsaturated monomer containing at least one carboxyl group or carboxylic anhydride group is used in the photosensitive resin composition in the...

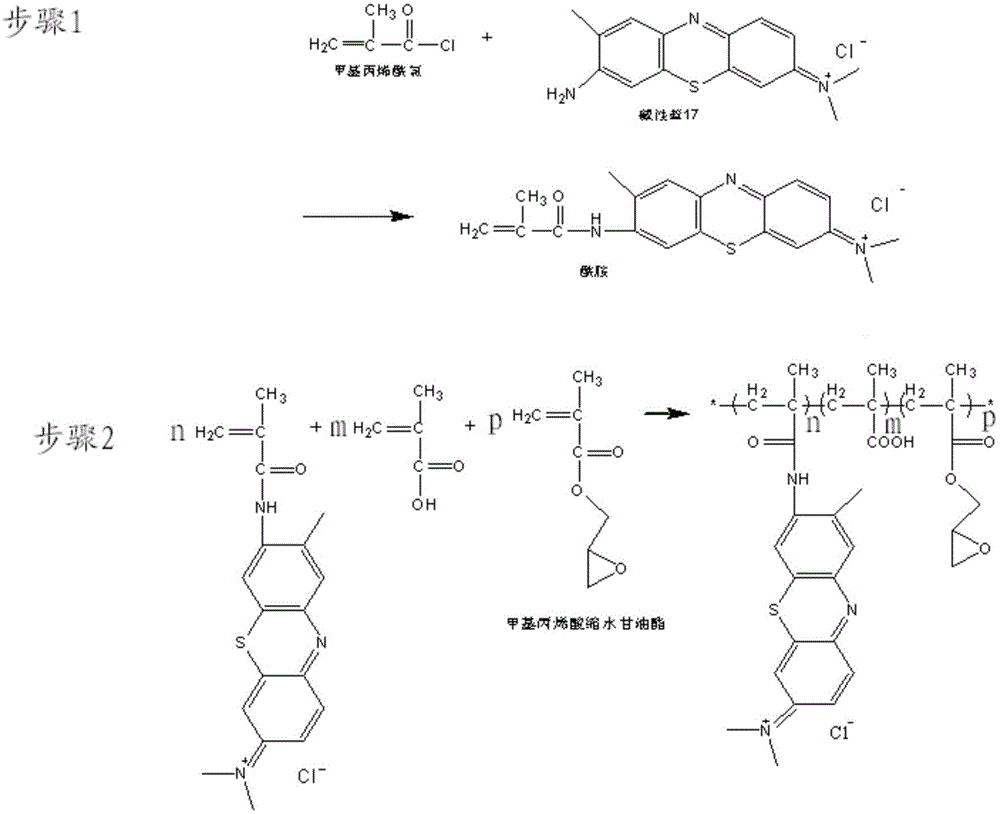

Embodiment 1

[0100] This embodiment provides a dye compound and a preparation method thereof, the structural formula of the dye compound (marked as a1) is as follows,

[0101]

[0102] Wherein, n, m, p are integers greater than 1; the molecular weight of the dye compound is 8000.

[0103] The dye compound a1 having the above structure is prepared by the following steps;

[0104] 1) Preparation of amide compound step

[0105] For the specific preparation flow chart, see figure 1 , add 50 parts by weight of triethylamine as a solvent to a three-necked flask containing 30 parts by weight of methacryloyl chloride, then add 20 parts by weight of basic blue 17, react at 10°C for 3 hours, then filter and rotary evaporate to obtain Amide compounds.

[0106] 2) Copolymerization step

[0107] A nitrogen inlet, a stirrer, a heater, a condenser tube and a thermometer are arranged on a four-necked conical flask with 1000 milliliters of solvent, and nitrogen is introduced, and 40 parts by weight ...

Embodiment 2

[0112] This embodiment provides a dye compound and a preparation method thereof, the structural formula of the dye compound (referred to as a2) is as follows,

[0113]

[0114] Wherein, n, m, p are integers greater than 1; the molecular weight of the dye compound is 12000.

[0115] The dye compound a2 with the above structure is prepared by the following steps, the specific preparation flow chart and figure 1 Similar no longer detailed drawing;

[0116] 1) Preparation of amide compound step

[0117] Add 50 parts by weight of triethylamine as a solvent to a three-neck flask containing 20 parts by weight of acryloyl chloride, then add 20 parts by weight of Basic Red 2, react at 2°C for 2 hours, then filter and rotary evaporate to obtain an amide compound.

[0118] 2) Copolymerization step

[0119] A nitrogen inlet, a stirrer, a heater, a condenser tube and a thermometer are arranged on a four-necked Erlenmeyer flask with 1000 ml of solvent, and nitrogen is introduced, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com