Halogen-free environment-friendly weather-resistant color master batch and preparation method

A color masterbatch, environmentally friendly technology, applied in the field of plastic processing, can solve the problems of difficult continuous control of product quality, increased production costs, and uneven quality, and achieve the effects of improving product competitiveness, convenient operation, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

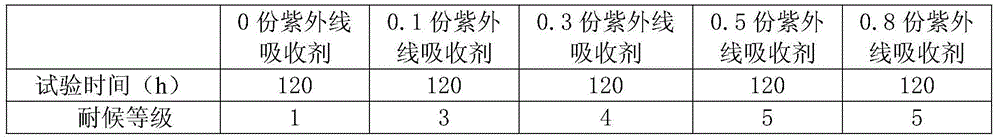

Image

Examples

Embodiment 1

[0019] A halogen-free environment-friendly weather-resistant color masterbatch, which is composed of the following raw materials in parts by weight: 40 parts of ethylene-vinyl acetate copolymer, 20 parts of low-density polyethylene, 15 parts of halogen-free environmental protection toner, and 0.5 parts of zinc stearate , 1 part of polyethylene wax, 0.3 part of antioxidant (the weight ratio of polyphenol antioxidant to the phosphite antioxidant is 2:1), 2,2'-methylenebis(4-tert-octyl Base-6-benzotriazole phenol) 0.3 parts.

[0020] The method for preparing environment-friendly weather-resistant masterbatch, described method comprises the following steps:

[0021] 1) Adding each raw material into a high-speed mixer in corresponding proportions for mixing, and stirring for 3 minutes at a stirring speed of 1500 r / min to obtain a mixture;

[0022] 2) Put the mixture into the double-helix granulator, set the processing parameters as follows: temperature in zone 1 is 100°C, temperat...

Embodiment 2

[0025] A halogen-free environment-friendly weather-resistant color masterbatch, which is composed of the following raw materials in parts by weight: 50 parts of ethylene-vinyl acetate copolymer, 25 parts of low-density polyethylene, 20 parts of environmental protection toner, 0.75 parts of zinc stearate, poly 1.5 parts of ethylene wax, 0.4 parts of antioxidant (the weight ratio of polyphenol antioxidant to the phosphite antioxidant is 1:1), 2,2'-methylenebis(4-tert-octyl- 6-benzotriazole phenol) 0.4 parts.

[0026] A method for preparing a halogen-free environment-friendly weather-resistant masterbatch, the method comprising the following steps:

[0027] 1) Adding each raw material into a high-speed mixer in corresponding proportions for mixing, and stirring for 4 minutes at a stirring speed of 2000 r / min to obtain a mixture;

[0028] 2) Put the mixture into a double-helix granulator, set the processing parameters as follows: first zone temperature 105°C, second zone temperat...

Embodiment 3

[0031] A halogen-free environment-friendly weather-resistant color masterbatch, which is composed of the following raw materials in parts by weight: 60 parts of ethylene-vinyl acetate copolymer, 30 parts of low-density polyethylene, 25 parts of environmental protection toner, 1 part of zinc stearate, poly 2 parts of ethylene wax, 0.5 parts of antioxidant (the weight ratio of polyphenol antioxidant to the phosphite antioxidant is 1:2), 2,2'-methylenebis(4-tert-octyl- 6-benzotriazole phenol) 0.5 part.

[0032] A method for preparing a halogen-free environment-friendly weather-resistant masterbatch, the method comprising the following steps:

[0033] 1) Adding each raw material into a high-speed mixer in corresponding proportions for mixing, and stirring for 5 minutes at a stirring speed of 3000 r / min to obtain a mixture;

[0034] 2) Put the mixture into a double-helix granulator, set the processing parameters as follows: temperature in zone 1 is 110°C, temperature in zone 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com