Method for preparing wafer-grade large-size hexagonal boron nitride on substrate

A hexagonal boron nitride, wafer-level technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of small area of hexagonal boron nitride, low coverage, poor uniformity, etc. , to achieve the effect of large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

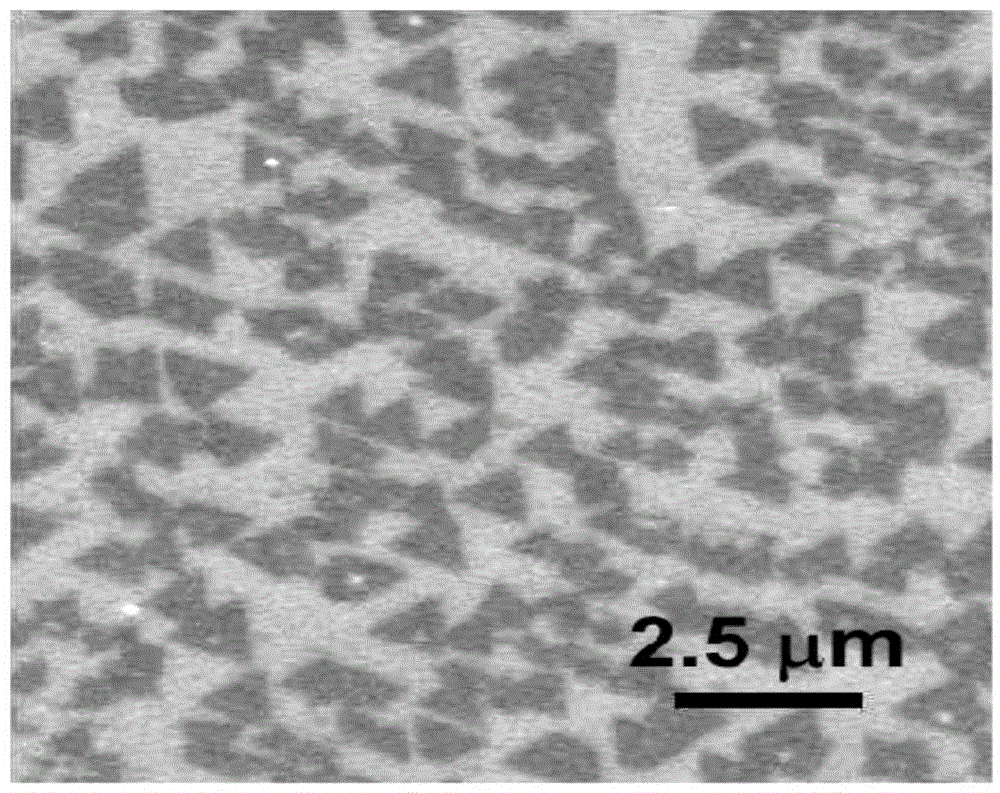

[0023] First, hexagonal boron nitride is grown controllably on Cu foil.

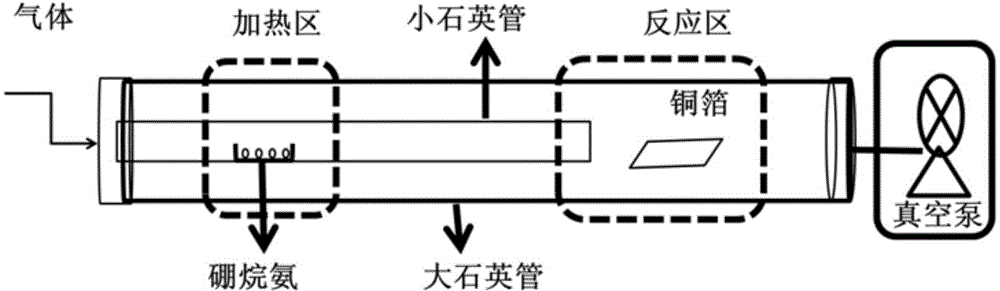

[0024] 1) Put 0.5mg Borazane powder in a quartz boat into a slender quartz tube, and put it into a three-temperature zone CVD device, such as figure 1 shown. Adjust the position so that the Borazane powder is in the middle of the first temperature zone, connect the slender small quartz tube to the vent, and then put the cleaned Cu foil into the third temperature zone of the CVD device, and ensure that it is in the third temperature zone. In the middle of the temperature zone, there are Borazane powder and Cu foil in sequence along the direction of airflow. The vacuum chamber is sealed with a rubber ring flange, and the predetermined temperature rise parameters and ventilation parameters are input into the computer to prepare for the subsequent heating of the three temperature zones of CVD. Start to vacuumize the cavity, first use a mechanical oil pump until the vacuum reaches 2×10 -2 At Torr, turn on ...

Embodiment 2

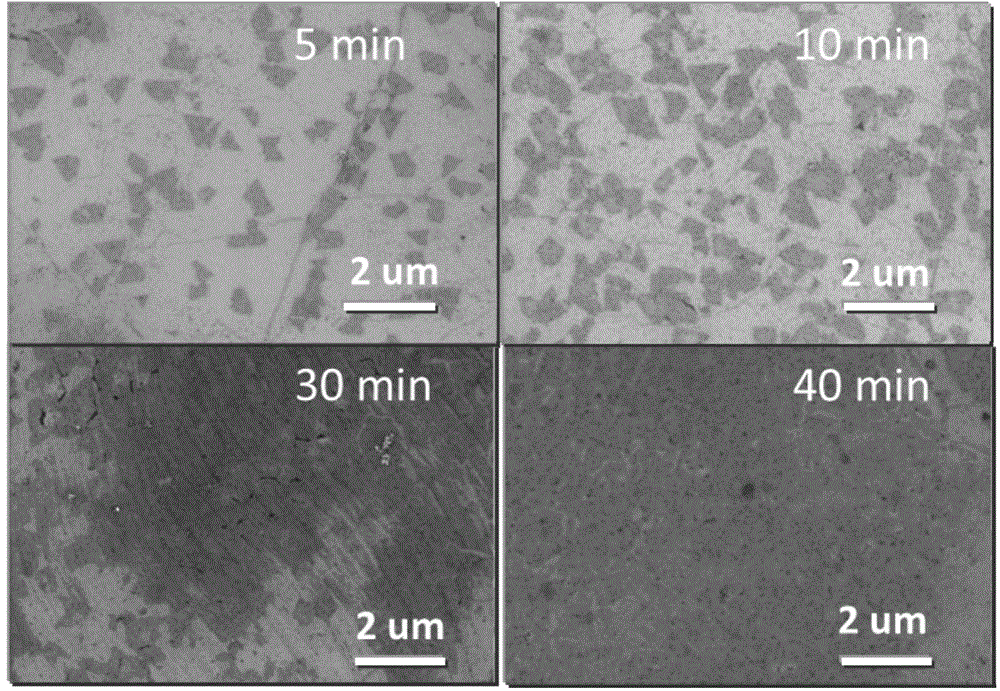

[0027] Example 2: Growing large-area continuous boron nitride

[0028] 1) As in Example 1, put the precursor into a 1mg Borazane powder in a quartz boat and place it in a small, slender quartz tube, and put it into a three-temperature zone CVD device, such as figure 1 shown. Adjust the position so that the Borazane powder is in the middle of the first temperature zone, connect the slender small quartz tube to the air vent, take a 7cm×7cm copper foil to clean, and then bend the cleaned Cu foil into the CVD device. The third temperature zone, and ensure that it is in the middle of the third temperature zone, Borazane powder and Cu foil along the direction of airflow. The remaining steps are the same as in Example 1, and the growth time is increased to 40 minutes.

[0029] 2) The transfer procedure is the same as above. Due to the large increase in the transfer sample area, the original tool can no longer be used for stable transfer. When the Cu foil is completely melted, use a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com