Infrared nonlinear optical crystal material, preparation method and application thereof

A nonlinear optics and crystal material technology, applied in the field of nonlinear optical materials, can solve the problems of unsatisfactory comprehensive performance, low laser damage threshold, large crystal growth, etc., and achieve excellent infrared nonlinear optical performance, simple steps, and crystallinity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 powder crystal sample

[0036] Mix the raw materials with the flux, grind them evenly, place them in a quartz reaction tube, and vacuum them to 10 -2 Pa and use a hydrogen-oxygen flame to melt and seal the quartz reaction tube. Put the quartz reaction tube into a high-temperature furnace, heat it to the solid melting temperature, and keep it for a period of time. Then the temperature is programmatically lowered to 300° C. at a speed not exceeding 5° C. / hour, then the heating is stopped, and the nonlinear optical crystal material is obtained by naturally cooling to room temperature.

[0037] The sample number, type and ratio of raw materials, type and amount of flux, solid melting temperature and holding time are shown in Table 1. The substances represented only by element symbols in the table are simple substances.

[0038] Table 1

[0039]

[0040]

Embodiment 2

[0041] The preparation of embodiment 2 single crystal samples

[0042] Raw material type and proportioning are the same as sample 2 in embodiment 1 # , the raw materials and flux are ground evenly and placed in a quartz reaction tube, vacuumed to 10 -2 Pa and use a hydrogen-oxygen flame to melt and seal the quartz reaction tube. Put the quartz reaction tube into a high-temperature furnace, heat it to 650°C, keep it for 2 hours, then raise the temperature to 950°C and keep it for 24 hours, then cool it down to 300°C at a rate of no more than 5°C / hour, then stop heating and let it cool naturally to room temperature to obtain the single crystal sample of the nonlinear optical crystal material, denoted as sample 7 #.

Embodiment 3

[0043] The structural characterization of embodiment 3 sample

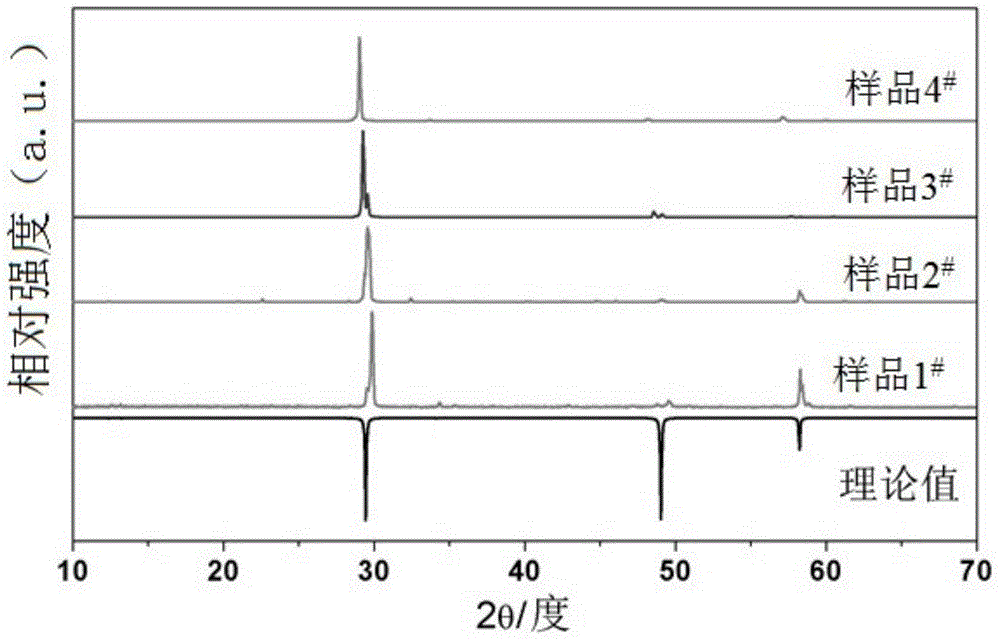

[0044] sample 1 # ~7 # The X-ray powder diffraction phase analysis (XRD) was carried out on the MiniFlex II X-ray diffractometer of Rigaku Company, Cu target, Kα radiation source (λ=0.154184nm). The result shows that the sample 1 prepared by embodiment 1 and 2 # ~7 # Both are samples of high purity and high crystallinity, typical representatives such as figure 1 Medium sample 1 # ~4 # The XRD spectrum. Sample 5 # ~Sample 7 # The XRD spectrum result and figure 1 The same, that is, the position and shape of the diffraction peaks are basically the same, and the relative peak intensity fluctuates within ±5%. Description Sample 1 # ~7 # have the same crystal structure.

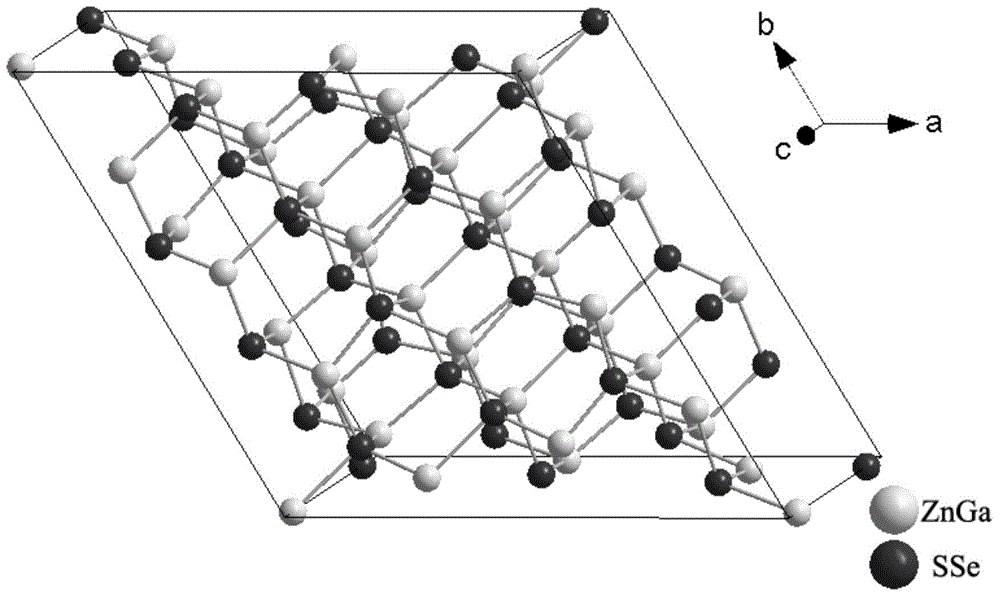

[0045] Sample 7 # The X-ray single crystal diffraction was carried out on a Mercury CCD type single crystal diffractometer, Mo target, Kα radiation source (λ=0.07107nm), test temperature 293K. And through Shelxtl97 for structural analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com