A kind of cinnamon oil microcapsule fabric finishing liquid and its preparation method and application

A fabric finishing and microcapsule technology, which is applied in the field of microcapsule preparation, can solve the problems of textile air permeability, reduced comfort, poor affinity between microcapsules and fibers, single function of textiles, etc., to achieve good appearance and better slow-release effect , the effect of convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

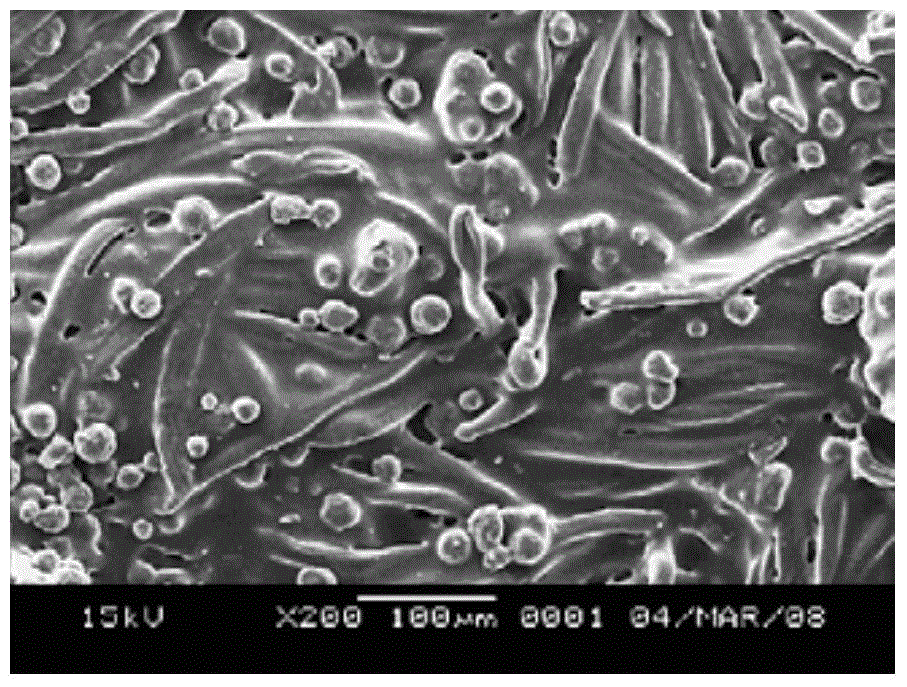

[0066] 1. Preparation of cinnamon oil microcapsules

[0067] 1.1 Chitosan quaternary ammonium salt solution: Dissolve 1.5g chitosan quaternary ammonium salt (HACC) in 150mL 0.5% acetic acid solution, stir to make it completely dissolve to obtain a 1.0% chitosan quaternary ammonium salt solution.

[0068] 1.2 Emulsification of cinnamon oil: Dissolve 3.0g of gum arabic (GA) in 150mL of distilled water, add 1.5g of Tween-80 and mix well, then add 2.25g of cinnamon oil and 1.5g of Span-80. Shear emulsification at 2000r / min for 10min.

[0069] 1.3 Complex coagulation reaction: drop the above-mentioned gum arabic emulsion into the chitosan quaternary ammonium salt solution, adjust the pH value to 5.0 with 10% sodium hydroxide (NaOH) after it is mixed evenly, heat in a water bath at 45°C for 30min, and stir at a speed of 400r / min.

[0070] 1.4 Cross-linking reaction: put the above reaction solution in an ice bath to cool down to 0-5°C, add 5g of 25% glutaraldehyde solution, cross-l...

Embodiment 2

[0097] 1. Preparation of cinnamon oil microcapsules

[0098] 1.1 Chitosan quaternary ammonium salt solution: Dissolve 1.5g chitosan quaternary ammonium salt (HACC) in 150mL 0.5% acetic acid solution, stir to make it completely dissolve to obtain a 1.0% chitosan quaternary ammonium salt solution.

[0099] 1.2 Emulsification of cinnamon oil: Dissolve 1.5g of gum arabic (GA) in 150mL of distilled water, add 1.5g of Tween-80 and mix well, then add 3.0g of cinnamon oil and 1.5g of Span-80. Shear emulsification at 3000r / min for 5min.

[0100] 1.3 Complex coagulation reaction: drop the above-mentioned gum arabic emulsion into the chitosan quaternary ammonium salt solution, adjust the pH value to 6.0 with 10% sodium hydroxide (NaOH) after it is mixed evenly, heat in a water bath at 40°C for 30min, and stir at a speed of 400r / min.

[0101] 1.4 Cross-linking reaction: put the above reaction solution in an ice bath to cool down to 0-5°C, add 8g of 25% glyoxal solution, cross-link and s...

Embodiment 3

[0127] 1. Preparation of cinnamon oil microcapsules

[0128] 1.1 Chitosan quaternary ammonium salt solution: 3.0 g of chitosan quaternary ammonium salt (HACC) was dissolved in 150 mL of 0.5% acetic acid solution, and stirred to completely dissolve to obtain a 2.0% chitosan quaternary ammonium salt solution.

[0129] 1.2 Emulsification of cinnamon oil: Dissolve 3.0 g of gum arabic (GA) in 150 mL of distilled water, add 3 g of OP-10 emulsifier, stir and mix well, then add 6 g of cinnamon oil, and shear and emulsify at 2500 r / min for 8 min.

[0130] 1.3 Complex coagulation reaction: drop the above-mentioned gum arabic emulsion into the chitosan quaternary ammonium salt solution, adjust the pH value to 5.5 with 10% sodium hydroxide (NaOH) after it is mixed evenly, heat in a water bath at 45°C for 30min, and stir at a speed of 500r / min.

[0131] 1.4 Cross-linking reaction: Place the above reaction solution in an ice bath to cool down to 0-5°C, add 3g of 25% glutaraldehyde solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com