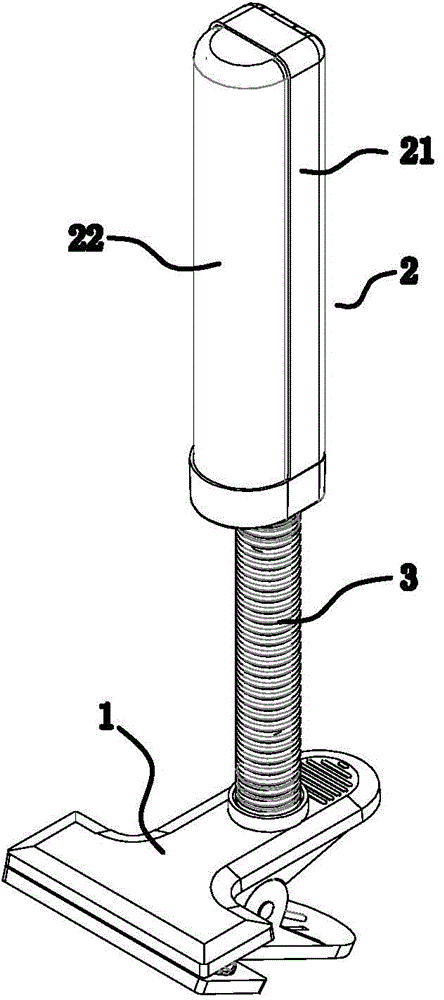

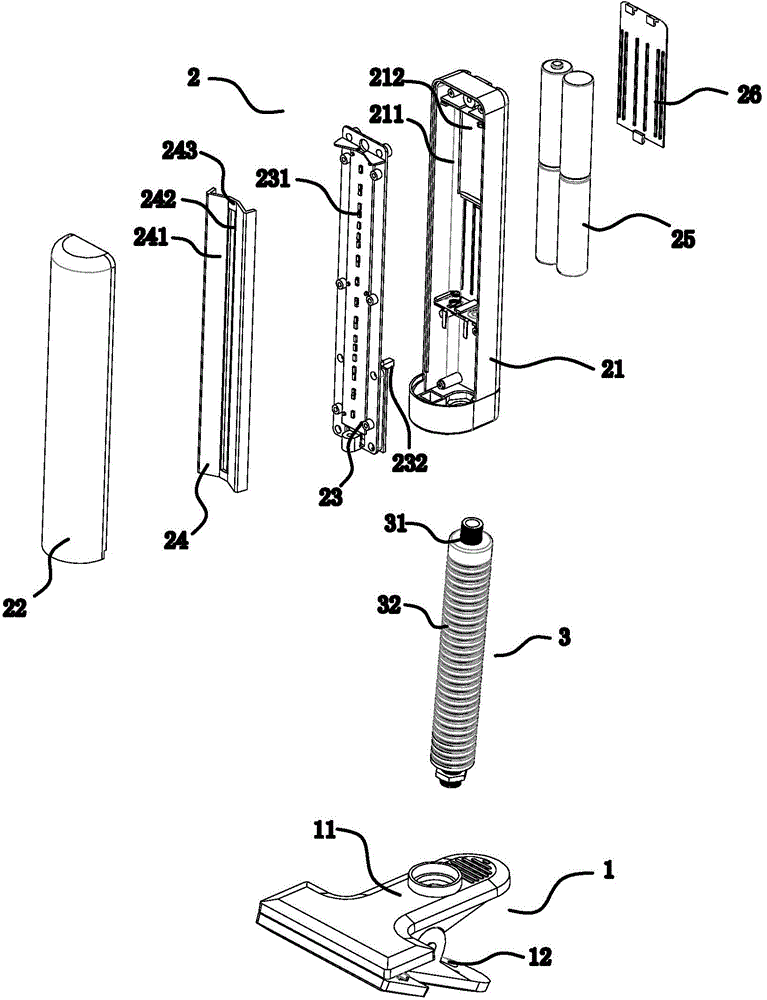

Clip lamp

A clip lamp and clip holder technology, applied in the field of lighting, can solve the problems of incompetence, high cost of converting power supply, complex structure, etc., and achieve the effects of being convenient to place, carry, and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After the raw materials are sieved, 12% of colorless transparent crystal grains, 67% of high-purity white quartz sand and 13% of sodium borate are fully mixed and evenly put into a closed kettle melting furnace for sintering at a temperature of 1850-1900, and the sintering atmosphere is helium Mix gas with chlorine gas (the mole fraction of chlorine gas in the mixed gas accounts for 10-15% of the total molar gas), after fully melting, stir with a fork-type stirrer at low speed (stirring speed 60-100rpm), keep warm and keep the molten state for 30min, Finally, put into the powder mixture of nano-scale silver bromide 2.5% and nano-scale sensitizer (copper chloride 0.6%) encapsulated in high-purity quartz glass tube, the defoamer is sodium nitrite, and then fully mix and stir for 3-5min It can be discharged, and after tape-casting (the thickness of the molding is any one of 0.3-0.5mm, to meet the actual light source power and illumination requirements, such as 0.3mm, 0.4mm,...

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is only: colorless transparent crystal grain 13%, high-purity white quartz sand 66%, sodium borate 15%, nanoscale silver bromide 2%, nanoscale sensitizer (chlorination Cadmium 0.5%).

Embodiment 3

[0033] The difference between embodiment 3 and embodiment 1 is only: colorless transparent crystal grain 14%, high-purity white quartz sand 68%, sodium borate 13%, nanoscale silver bromide 3%, nanoscale sensitizer (chlorination Copper 0.3% and Cadmium Chloride 0.6% mixture).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com