A kind of backplane for photovoltaic cells and preparation method thereof

A photovoltaic cell and backplane technology, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of poor barrier properties of PC films and PA films, poor aging resistance of backplanes, and high water absorption, and achieves high Mechanical properties and temperature resistance, superior water vapor barrier properties, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

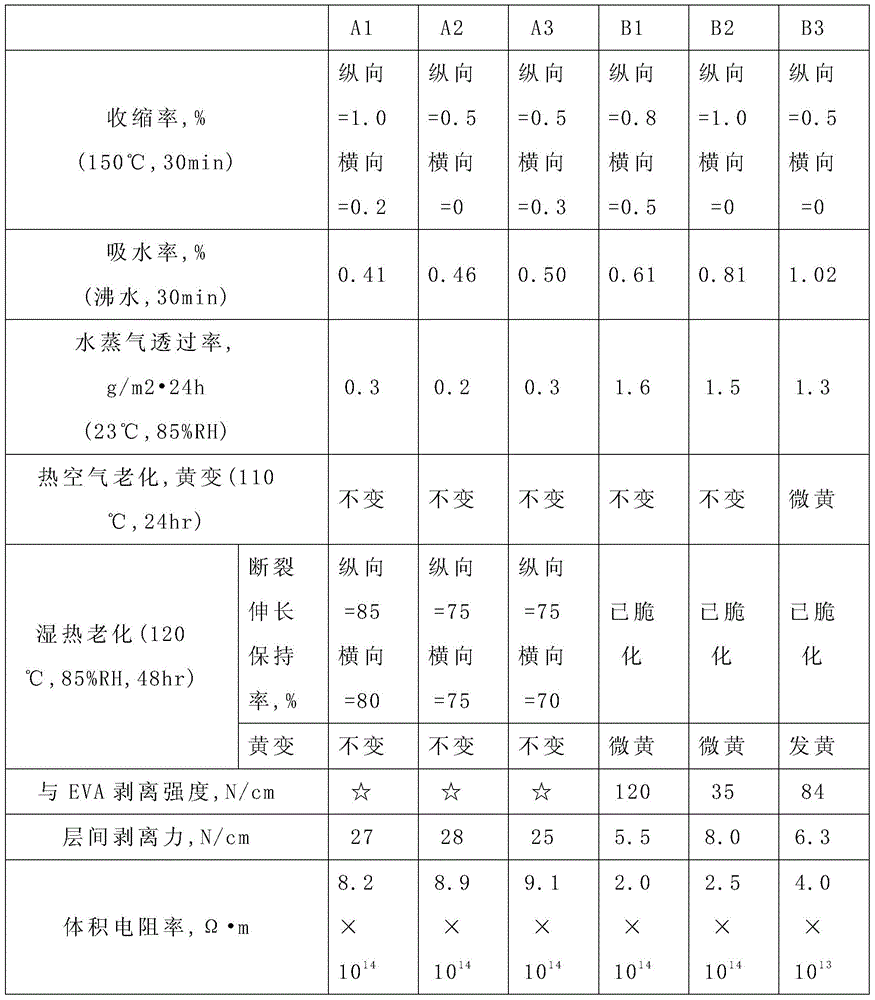

Examples

Embodiment 1

[0030] (1) Preparation of inner surface material

[0031] Put 100 parts of metallocene polyethylene 1327ED (U.S. Exxon Chemical Company) into a high mixer, add 0.15 parts of ultraviolet light absorber 2-hydroxyl-4-n-octyloxybenzophenone (Beijing Institute of Addition Auxiliaries , GW531), 0.15 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate (Beijing Institute of Addition Auxiliaries, GW480), stirring for 30 minutes, the speed 650 rpm, mix the materials evenly and put them into the A screw of the three-layer co-extrusion sheet unit, the screw diameter is 60 mm, and the aspect ratio is 33.

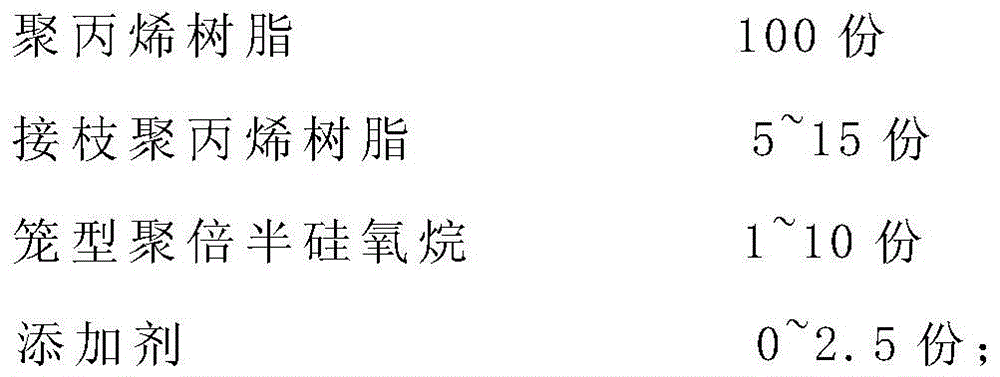

[0032] (2) Preparation of middle layer material

[0033] Put 100 parts of polypropylene resin BI750 (Korea Samsung Total Company), 15 parts of grafted polypropylene resin BONDYRAM1001 (Israel Pryron Company) into a high-speed mixer, add 10 parts of cage polysilsesquioxane SH1311 (U.S. Hybrid Plastics company), 0.2 parts of UV absorber 2-hydroxy-4-n-octyloxybenzoph...

Embodiment 2

[0039] (1) Preparation of inner surface material

[0040] Put 100 parts of EVA resin 14-2 (Beijing Organic Chemical Factory) into a high mixer, add 0.15 parts of ultraviolet light absorber 2-hydroxyl-4-n-octyloxybenzophenone, 0.15 parts of light stabilizer bis(2, 2,6,6-Tetramethyl-4-piperidinyl) sebacate, stirred for 30 minutes, the speed was 650 rpm, and the materials were evenly mixed and put into the A screw of the three-layer co-extrusion sheet unit, the screw The diameter is 60 mm and the aspect ratio is 33.

[0041] (2) Preparation of middle layer material

[0042] Put 100 parts of polypropylene resin 50E725 (U.S. DuPont), 15 parts of grafted polypropylene resin FUSABOND 353D (U.S. DuPont) into a high-speed mixer, add 8 parts of cage polysilsesquioxane SH1311 (U.S. HybridPlastics), 0.3 parts of UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.3 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate , 0.3 parts of antioxidant tetrakis[β-(3',5'-di-te...

Embodiment 3

[0048] (1) Preparation of inner surface material

[0049] Put 100 parts of EVA resin 14-2 (Beijing Organic Chemical Factory) into a high mixer, add 0.2 parts of ultraviolet light absorber 2-hydroxyl-4-n-octyloxybenzophenone, 0.2 parts of light stabilizer bis(2, 2,6,6-Tetramethyl-4-piperidinyl) sebacate, stirred for 30 minutes, the speed was 650 rpm, and the materials were evenly mixed and put into the A screw of the three-layer co-extrusion sheet unit, the screw The diameter is 60 mm and the aspect ratio is 33.

[0050] (2) Preparation of middle layer material

[0051] Put 100 parts of polypropylene resin PT182 (Taiwan Fuju Company), 10 parts of grafted polypropylene resin FH118 (Ningbo Nengzhiguang New Material Technology Co., Ltd.) into the high-speed mixer, and add 10 parts of cage polysilsesquioxane SH1311 (U.S. Hybrid Plastics Company), 0.2 parts of UV absorber 2-hydroxyl-4-n-octyloxybenzophenone, 0.2 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piper Pyridyl) s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com