Production method for extracting mushroom mycelium of lentinan

A technology of lentinan and a production method, which is applied in the directions of botanical equipment and methods, application, mushroom cultivation, etc., can solve the problems of staying in the experimental stage of theoretical research, large equipment investment and high production cost, and achieves shortening of cultivation time, environmental protection, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of production method of the mushroom mycelium that is used to extract lentinan, is characterized in that comprising the following steps:

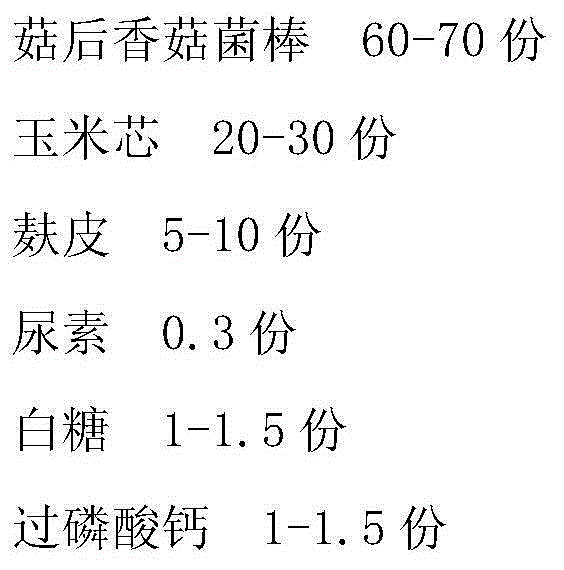

[0026] Step 1, weigh the material, weigh the mushroom sticks, corncobs, bran, urea, white sugar, superphosphate and gypsum according to the formula, and the mass ratio is:

[0027]

[0028]

[0029] Step 2, pretreatment of the base material, first crush the shiitake mushroom sticks and corn cobs weighed in step 1 into 0.3-0.5cm sized particles, mix the shredded shiitake mushroom sticks and corn cobs, and add to the mixture Add the cellulase parent matter in the mixture, the mass ratio of the cellulase parent matter to the pulverized shiitake mushroom stick and corn cob mixture is 5%, adjust the dry humidity with water, and control the water content at 40-50%, and use acetic acid Adjust the pH to 4.5-5.5, mix well, put it into the cement pool and smooth it gently, keep the material plane 20-30cm lower than the pool mouth,...

Embodiment 2

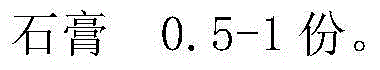

[0036] Step 1, weigh the material, weigh the mushroom sticks, corncobs, bran, urea, white sugar, superphosphate and gypsum according to the formula, and the mass ratio is:

[0037]

[0038] Step 2, pretreatment of the base material, first crush the shiitake mushroom sticks and corn cobs weighed in step 1 into 0.3-0.5cm sized particles, mix the shredded shiitake mushroom sticks and corn cobs, and add to the mixture Add the base material after degradation, the base material after degradation is obtained through the base material pretreatment step in embodiment 1, the mass ratio of the base material after degradation and the mixture of shiitake mushroom sticks and corncobs after crushing is 20%. Adjust the dry humidity with water to control the water content at 50%, adjust the pH to 4.5-5.5 with acetic acid, mix well, put it into the cement pool and smooth it with light pressure, keep the material level 20-30cm below the pool mouth, cover with plastic film, Vents are left at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com