Mesoporous alumina nickel-based catalyst with high activity and high stability for CO2 reforming CH4 reaction and preparation method of mesoporous alumina nickel-based catalyst

A catalyst and mesoporous technology, applied in the field of mesoporous aluminum-nickel-based catalysts and their preparation, can solve problems such as sulfide poisoning, expensive noble metal catalysts, harsh operating conditions, etc., and achieve large pore volume, high catalytic activity and stability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

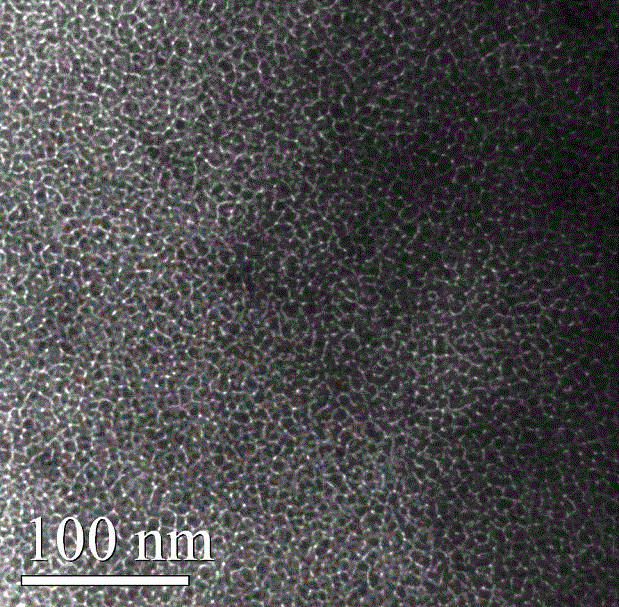

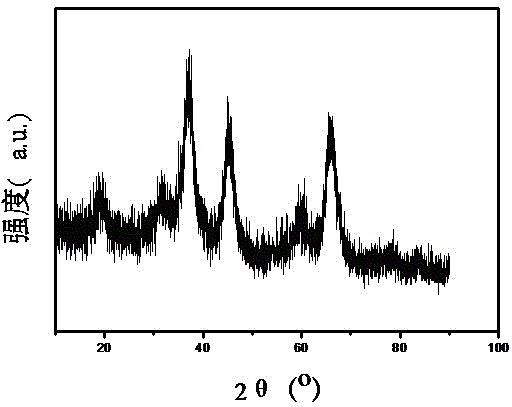

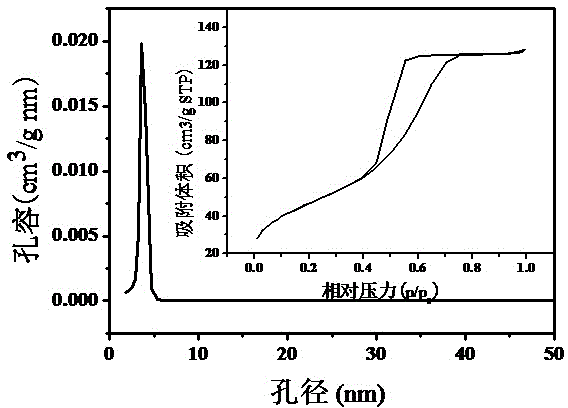

Image

Examples

Embodiment 1

[0040] The preparation steps in the present embodiment are as follows:

[0041] a. Add 3.9 g Ni(NO 3 ) 2 .6H 2 O and 37.5 g Al(NO 3 ) 3 .9H 2 O was dissolved in 50 mL of deionized water to obtain a uniformly mixed solution so that the concentration of aluminum ions was 2 mol / L;

[0042] b. Under the condition of 75 ℃, add ammonium carbonate solution with a concentration of 1 mol / L to the above solution drop by drop while stirring, control the titration rate of ammonium carbonate to 0.4 mL / min, and stop immediately after the sol is obtained through the titration reaction Titration, control the pH value of the titrated sol to be 5.0~5.5;

[0043] c. Aging the sol formed by titration at room temperature for 24 hours at a constant temperature, spread it in an open container with a thickness of no more than two centimeters, and dry it at a constant temperature of 100°C for 24 hours;

[0044] d. Calcining the above-mentioned dried gel at 200 °C for 10 h at a heating rate of...

Embodiment 2

[0048] The preparation steps in the present embodiment are as follows:

[0049] a. Add 4.1g Ni(NO 3 ) 2 ·6H 2 O, 0.6g La(NO 3 ) 3 ·nH 2 O and 37.5g Al(NO 3 ) 3 9H 2 O was dissolved in 50mL of deionized water to obtain a uniformly mixed solution so that the concentration of aluminum ions was 2mol / L;

[0050] b. Under the condition of 75 ℃, add ammonium carbonate solution with a concentration of 1mol / L to the above solution drop by drop while stirring, and control the titration rate of ammonium carbonate to about 0.4 mL / min, so that after the titration reaction to obtain the sol Stop the titration immediately, and control the pH value of the titrated sol to be 5.0~5.5;

[0051] c. Aging the sol formed by titration at room temperature for 24 hours at a constant temperature, spread it in an open container with a thickness of no more than two centimeters, and dry it at a constant temperature of 100°C for 24 hours;

[0052] d. Calcining the above-mentioned dried gel at 2...

Embodiment 3

[0055] The preparation steps in the present embodiment are as follows:

[0056] a. Add 4.1g Ni(NO 3 ) 2 ·6H 2 O, 0.6g Ce(NO 3 ) 3 ·6H 2 O and 37.5g Al(NO 3 ) 3 9H 2 O was dissolved in 50mL of deionized water to obtain a uniformly mixed solution so that the concentration of aluminum ions was 2mol / L;

[0057] b. Under the condition of 75 ℃, add ammonium carbonate solution with a concentration of 1mol / L to the above solution dropwise while stirring, and control the titration rate of ammonium carbonate to about 0.4mL / min, so that after the titration reaction to obtain the sol Stop the titration immediately, and control the pH value of the titrated sol to be 5.0~5.5;

[0058] c. Aging the sol formed by titration at room temperature for 24 hours at a constant temperature, spread it in an open container with a thickness of no more than two centimeters, and dry it at a constant temperature at 100°C for 24 hours;

[0059] d. Calcining the above-mentioned dried gel at 200 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com