Catalyst for synthesizing light olefins, preparation method and use method thereof

A technology of low-carbon olefins and catalysts, which is applied in the field of catalysts, preparations and applications for the synthesis of low-carbon olefins. It can solve the problems of low activity and selectivity at low temperatures, achieve high activity and low-carbon olefins selectivity, and strengthen adsorption and activation. , to promote the effect of restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

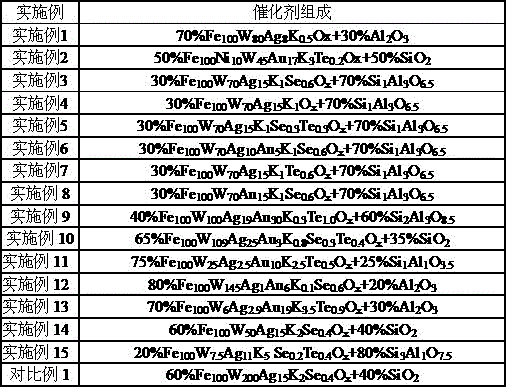

Examples

Embodiment 1

[0033] Dissolve 89.2 grams of ferric nitrate, 0.13 grams of potassium nitrate and 3.46 grams of silver nitrate in 100 ml of water to form solution Ⅰ of a certain concentration, dissolve 51.7 grams of ammonium metatungstate in 100 ml of water to obtain solution Ⅱ, add solution Ⅱ to solution Ⅰ Mixture I was obtained in , and 120 grams of aluminum sol with a mass content of 25% of alumina was added to mixture I and the pH value was adjusted to 8 with ammonia water to obtain mixture II. The mixture II was heated and concentrated in a boiling water bath to a solid content of 55% by weight to obtain a slurry material, the slurry was dried at 80°C with hot air with a relative humidity of 90% for 12 hours to obtain a catalyst precursor, and the catalyst precursor was roasted at 750°C for 3 hours to obtain a catalyst, the composition of which was: 70% Fe 100 W 80 Ag 8 K 0.5 Ox+30%Al 2 o 3 . The catalyst is pulverized and screened with 20-40 mesh particles for use.

Embodiment 2

[0035] Take 76.7 grams of ferric nitrate, 15.3 grams of chloroauric acid solution, 6.37 grams of nickel nitrate and 0.66 grams of potassium nitrate dissolved in 100 ml of water to make a certain concentration of solution I, 25 grams of ammonium metatungstate and 0.1 grams of ammonium tellurate dissolved in In 100 milliliters of water, solution II was obtained, solution II was added to solution I to obtain mixture I, 125 grams of silica sol with a silicon oxide mass content of 40% was added to mixture I and the pH value was adjusted to 8 with ammonia water to obtain mixture II, and mixture II was placed in Heat and concentrate in a boiling water bath to a solid content of 55% by weight to obtain a slurry, dry the slurry at 90°C with hot air with a relative humidity of 90% for 5 hours to obtain a catalyst precursor, and roast the catalyst precursor at 650°C for 5 hours to obtain Catalyst, its composition is: 50%Fe 100 Ni 10 W 45 Au 17 K 3 Te 0.2 Ox+50%SiO2 2 . The catalys...

Embodiment 3

[0037] Dissolve 40.3 grams of ferric nitrate, 0.12 grams of potassium nitrate and 2.93 grams of silver nitrate in 100 milliliters of water to form solution I with a certain concentration, and dissolve 0.12 grams of ammonium selenate and 20.4 grams of ammonium metatungstate in 100 milliliters of water to obtain solution II. Add solution II to solution I to obtain mixture I, add 49.3 grams of silica sol with a mass content of silicon oxide of 40% and 201.1 grams of aluminum sol with a mass content of alumina of 25% to mixture I and adjust the pH value to 10 with ammonia water to obtain mixture II , the mixture II was placed in a boiling water bath, heated and concentrated to a solid content of 55% by weight to obtain a slurry, and the slurry was dried at 80° C. with hot air with a relative humidity of 90% for 24 hours to obtain a catalyst precursor. The catalyst precursor was heated at 750 The catalyst was prepared by roasting at ℃ for 8 hours, and its composition was: 30% Fe 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com