Pantograph metal-impregnated carbon slider vacuum pressure infiltration method

A technology of vacuum pressure impregnation and metal impregnation, which is applied in the field of pantograph slide material preparation, which can solve problems affecting product performance, increasing processing costs, and wire wear, and achieves small wire wear, high dimensional accuracy control, and low resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

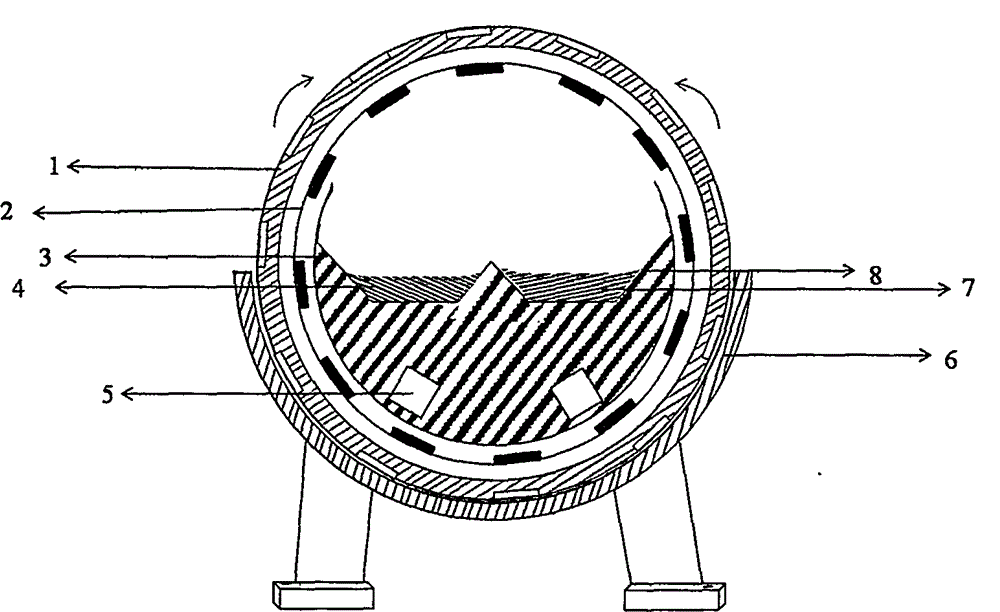

Image

Examples

Embodiment 1

[0027] In Example 1, the basic operation steps of preparing a pantograph-impregnated metal-carbon slide plate by vacuum pressure infiltration technology are as follows:

[0028] I), material composition of impregnated metal carbon slide plate

[0029] The material composition of metal-impregnated carbon skateboard is mainly copper-chromium alloy and carbon strip, wherein the chromium content in copper-chromium alloy is 0.8wt%; the composition of carbon strip is calcined petroleum coke, graphite powder and pitch, and the density of carbon strip is 1.62g / cm 3 , the porosity is 12%, and the average pore size is 0.6 μm.

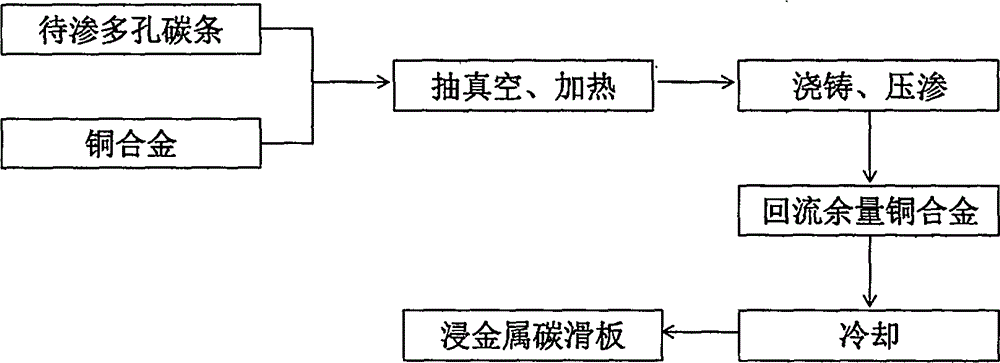

[0030] II), the basic steps of vacuum pressure impregnation (technical process sees attached figure 2 )

[0031] 1) First place the porous carbon strip to be infiltrated and the copper-chromium alloy in the graphite boat respectively.

[0032] 2) Then vacuumize. While removing the air in the furnace body, the air in the pores of the porous carbon strip is di...

Embodiment 2

[0038] The difference from Example 1 is that this Example 2 uses copper-titanium alloy and carbon strips.

[0039] The basic operation steps of the metal-carbon slide plate impregnated with the pantograph in Example 2 are as follows:

[0040] I), material composition of impregnated metal carbon slide plate

[0041] The material components of the metal-impregnated carbon slide plate are mainly copper-titanium alloy and carbon strips, wherein the titanium content in the copper-titanium alloy is 1 wt%, and the composition of the carbon strips is the same as that in Example 1.

[0042] II), the basic steps of vacuum pressure impregnation (technical process sees attached figure 2 )

[0043] 1) First place the porous carbon strip to be infiltrated and the copper-titanium alloy in the graphite boat respectively.

[0044] 2) Then vacuumize. While removing the air in the furnace body, the air in the pores of the porous carbon strip is discharged. This process will promote the impr...

Embodiment 3

[0050] The difference from Example 1 is that this Example 3 uses carbon strips with low porosity, and the alloy is copper-chromium alloy.

[0051] The basic operation steps of the metal-carbon slide plate impregnated with the pantograph in Example 3 are as follows:

[0052] I), material composition of impregnated metal carbon slide plate

[0053] The material composition of the metal-impregnated carbon slide plate is mainly copper-chromium alloy and carbon strips, wherein the copper-chromium alloy is the same as in Example 1, and the composition of the carbon strips is calcined petroleum coke, graphite powder and pitch, and the density of the carbon strips is 1.65g / cm 3 , the porosity is 11%, and the average pore size is 0.7 μm.

[0054] II), the basic steps of vacuum pressure impregnation (technical process sees attached figure 2 )

[0055] 1) First place the porous carbon strip to be infiltrated and the copper-chromium alloy in the graphite boat respectively.

[0056] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com