Light curing device

A technology of light curing device and light pipe, which is applied in the field of light curing device, can solve the problems of poor mechanical properties and wear resistance, unreasonable setting position, poor curing of objects to be cured, etc., and achieve good curing effect and high work efficiency , Enhance the effect of light intensity and light range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

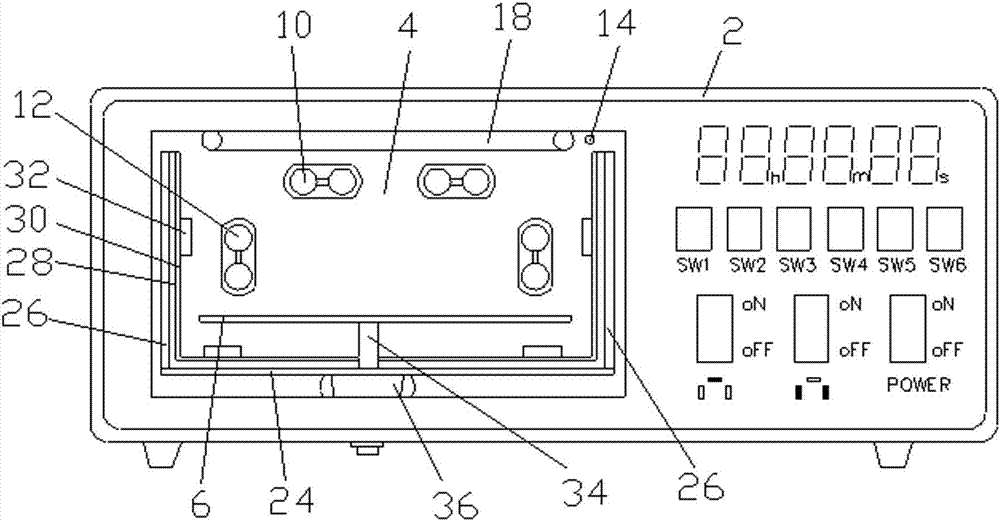

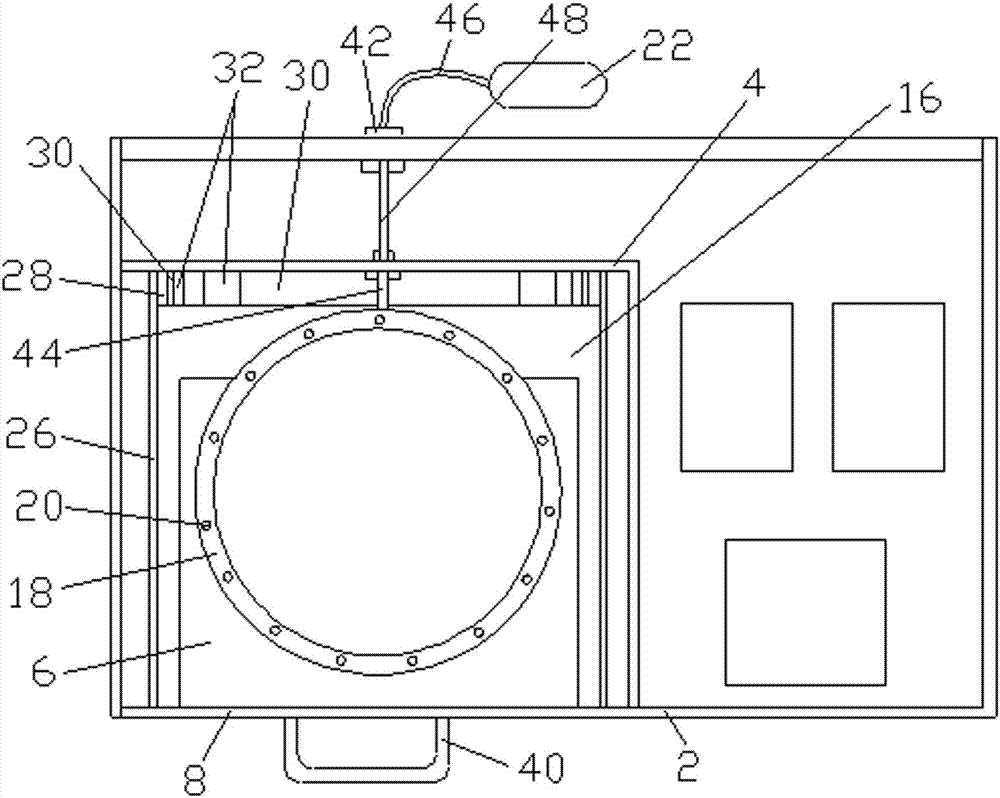

[0035] Such as figure 1 , figure 2 As shown, a photocuring device includes a casing 2 with an opening on the front side, a partition 4 inside the casing 2, and a movable shelf 6, on which the object to be cured is placed, and the opening is set There is an openable door panel 8, and the first row of UV light pipes and the second row of UV light pipes are arranged on the partition plate 4 above the shelf 6. The first row of UV light pipes includes two first UV light pipes 10, and the first row of UV light pipes 10. Two rows of UV light pipes include two second UV light pipes 12, the second UV light pipes 12 are lower than the first UV light pipes 10, the second UV light pipes 12 are located outside the first UV light pipes 10, and the first UV light pipes The arrangement of the tube 10 and the second UV light tube 12 has a strong light intensity and a wide light range, so that the curing effect of the object to be cured is good, and the product quality is improved.

[0036] ...

Embodiment 2

[0062] Such as Figure 6-Figure 10 As shown, the difference between the second embodiment and the first embodiment is that the two second UV light pipes 12 are arranged in a figure-eight structure, with strong illumination intensity and wide illumination range.

Embodiment 3

[0064] Such as Figure 11-Figure 14 As shown, a photocuring device includes a casing 2 with an opening on the front side, a partition 4 inside the casing 2, and a movable shelf 6, on which the object to be cured is placed, and the opening is set There is an openable door panel 8, and the first row of UV light pipes and the second row of UV light pipes are arranged on the partition plate 4 above the shelf 6. The first row of UV light pipes includes two first UV light pipes 10, and the first row of UV light pipes 10. Two rows of UV light pipes include two second UV light pipes 12, the second UV light pipe 12 is lower than the first UV light pipe 10, the second UV light pipe 12 is positioned at the outside of the first UV light pipe 10, and the shelf 6 There is a third row of UV light pipes below, the third row of UV light pipes includes two third UV light pipes 14, the arrangement of the first UV light pipe 10, the second UV light pipe 12 and the third UV light pipe 14 , the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com