Preparation method of nanometer alpha-Fe2O3

A -fe2o3, nanotechnology, applied in the field of preparation of nano-α-Fe2O3, can solve the problems of low particle dispersion, easy agglomeration, large crystal grains, etc., to improve the reactivity and selectivity, suitable particle size, uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

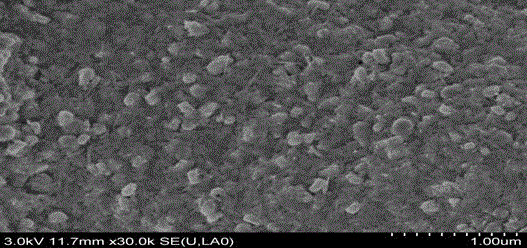

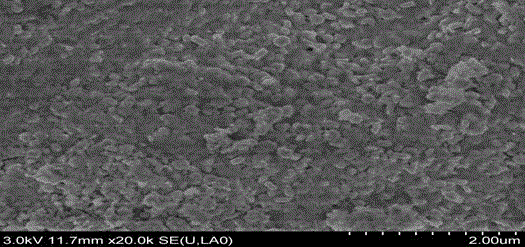

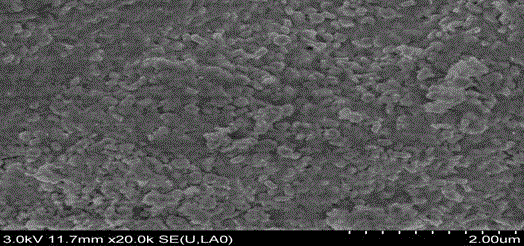

Image

Examples

Embodiment 1

[0025] Take 50g concentration of 10% Fe(NO 3 ) 3 solution, add 0.5 g of the active substance cetyltrimethylammonium bromide, after ultrasonic dissolution, add 10% NaOH solution under magnetic stirring and adjust the pH=7, then heat and boil under reflux for 4 hours, liquid-solid separation at 120°C for 5 hours, get nano α-Fe 2 o 3 .

Embodiment 2

[0027] Take 50g concentration of 10% Fe(NO 3 )3 Solution, add active substance polyethylene glycol 6000 1.0g and stir to dissolve, add 15% NaOH solution under magnetic stirring and adjust PH=8, then heat and boil for reflux for 5 hours, and separate liquid and solid at 140°C for 7 hours to obtain nano-α-Fe 2 o 3 .

Embodiment 3

[0029] Take 50g concentration of 10% Fe(NO 3 ) 3 Solution, add 1.5g of active substance polyethylene glycol 6000 statically mix and dissolve, add 20% NaOH solution under magnetic stirring and adjust PH = 9, then heat and boil for 6 hours, liquid-solid separation at 160°C for 9 hours to obtain nano-α- Fe 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com