Catalytic oxidative treatment process for ship wastewater

A catalytic oxidation, ship technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of long domestication time of bacteria, troublesome operation, fluctuation of water quality, etc. To achieve the effect of scientific management, simple operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

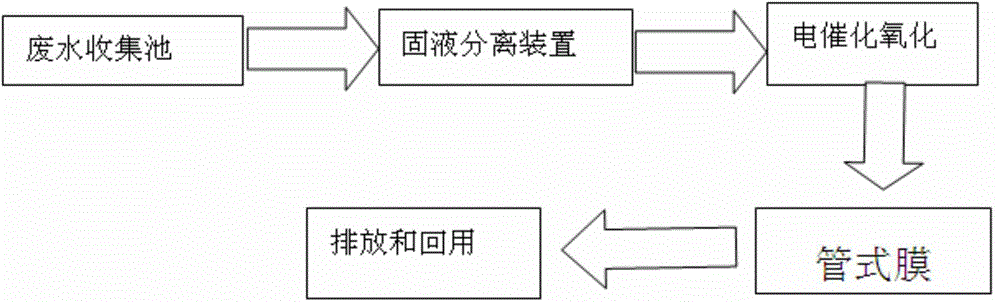

[0023] See figure 1 Shown: the present invention adopts following technical scheme, and processing method technological step is as follows:

[0024] (1) Put the domestic sewage and kitchen waste into the collection box, use the sludge pump to lift the raw water and send it to the wastewater mixing and grinding equipment, and grind the domestic sewage and kitchen waste (feces, food bones, fish bones, etc.) into 1 Particles around -2mm;

[0025] (2), and then enter the circulating water tank, and then enter the high-pressure airtight electro-oxidation device through the sludge stirring pump, and generate an electrochemical reaction with the help of an external high voltage;

[0026] (3) In the electro-oxidation device, it forms cracking, pushing flow, oxidation, sterilization, algae killing, and converts electrical energy into chemical energy. At the same time, ozone is added to form a form of dissolved oxygen inside, which can treat organic or inorganic substances in wastewate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com