Method for high-pressure liquid-phase isomerized production of acephate

An acephate, high pressure liquid phase technology, applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of large waste water discharge, easy decomposition of catalyst ammonium sulfide, and complicated operation. and other problems, to achieve the effect of reducing pollution, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

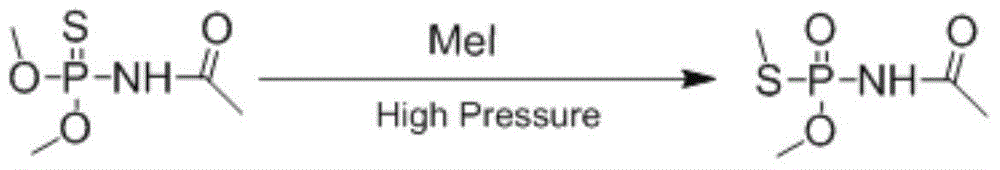

Image

Examples

Embodiment 1

[0020] Embodiment 1, a method for producing acephate by isomerization of acetylspermine under high pressure, using acetylspermine as raw material, the following steps are carried out successively:

[0021] (1) In the pressure vessel, add 1.83g (10mmol) acetylspermine and 71mg (0.5mmol) methyl iodide, in the air atmosphere, slowly compress the gas, thereby increasing the pressure of the vessel to 100Mpa, the reaction temperature is controlled at 50°C, Stop the reaction after shaking for 2 hours;

[0022] (2) Lower the temperature to room temperature, remove the pressure to normal pressure, open the pressure vessel, remove methyl iodide under reduced pressure, and reclaim acetylspermine (obtaining 0.09g acetylspermine) by distillation under reduced pressure to obtain the product acephate 1.74g (Yield 95.1%).

Embodiment 2

[0023] Embodiment 2, a method for producing acephate by isomerization of acetylspermine under high pressure, using acetylspermine as raw material, the following steps are carried out successively:

[0024] (1) In a pressure vessel, add 1.83g (10mmol) of acetylspermine and 71mg (0.5mmol) of methyl iodide, in an air atmosphere, slowly compress the gas, increase the pressure of the vessel to 150Mpa, control the reaction temperature at 60°C, and shake Stop reaction after reacting 6h;

[0025] (2) Lower the temperature to room temperature, remove the pressure to normal pressure, open the pressure vessel, remove methyl iodide under reduced pressure, and reclaim acetylspermine (obtaining 0.02g acetylspermine) by distillation under reduced pressure to obtain 1.81g of product acephate (Yield 98.9%).

Embodiment 3

[0026] Embodiment 3, a method for producing acephate by isomerization of acetylspermine under high pressure, using acetylspermine as raw material, the following steps are carried out in sequence:

[0027] (1) In a pressure vessel, add 1.83g (10mmol) acetylspermine and 71mg (0.5mmol) methyl iodide, in a nitrogen atmosphere, slowly compress the gas, increase the pressure of the vessel to 50Mpa, control the reaction temperature at 80°C, and shake Stop reaction after reacting 4h;

[0028] (2) Lower the temperature to room temperature, remove the pressure to normal pressure, open the pressure vessel, remove methyl iodide under reduced pressure, and reclaim acetylspermine (obtaining 0.27g acetylspermine) by distillation under reduced pressure to obtain 1.56g of product acephate (Yield 85.2%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com