Method for preparing pneumocandins B0 by adopting dynamic axial compression column system

An axial compression and dynamic technology, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems affecting the quality of carpafungin, unfavorable production application, and affecting production costs, etc., to achieve easy control, column The effect of bed stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Adjust the pH of the fermented liquid containing neomocontin to 2 for acid precipitation treatment, leach after filtration, centrifuge, add activated carbon for decolorization to obtain a colorless filtrate;

[0015] 2. Homogenize 20 μm silica gel with isopropanol, put it into a dynamic axial compression column, the column packing pressure is 6Mpa, and the column packing size is Φ50×250mm;

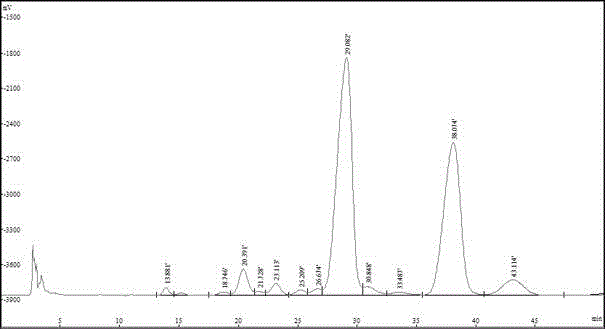

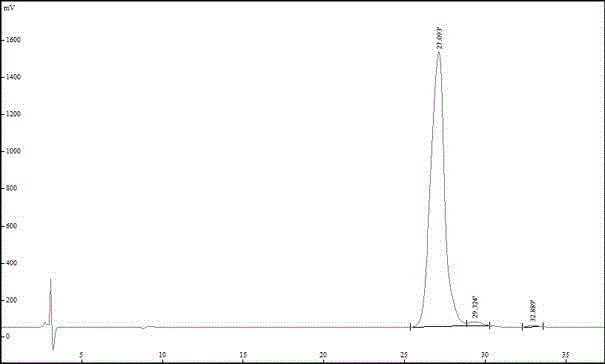

[0016] 3. Concentrate and dry the colorless filtrate obtained in step 1, add chloroform / methanol mixture (volume ratio 1:5) to dissolve and obtain a sample liquid, pump it into a dynamic axial compression column to prepare a chromatographic system, and use chloroform / methanol / water mixed solution for elution, the volume ratio of the eluent is 78 / 18 / 1, and the sample loading is 0.2 times the weight of the loaded silica gel. During the elution process, an ultraviolet detector was used for on-line monitoring with a wavelength of 280nm. According to the chromatogram, fractions with ...

Embodiment 2

[0018] 1. Adjust the pH of the fermented liquid containing neomocontin to 3 for acid precipitation treatment, leach after filtration, centrifuge, add activated carbon to decolorize to obtain a colorless filtrate;

[0019] 2. Homogenize 50 μm silica gel with isopropanol, put it into a dynamic axial compression column, the column packing pressure is 8Mpa, and the column packing size is Φ150×250mm;

[0020] 3. Concentrate and dry the colorless filtrate obtained in step 1, add chloroform / methanol mixture (volume ratio 1:4) to dissolve and obtain a sample liquid, pump it into a dynamic axial compression column to prepare a chromatographic system, and use chloroform / methanol / water mixture for elution, the volume ratio of the eluent is 82 / 17 / 3, and the sample loading is 0.25 times of the weight of the loaded silica gel. During the elution process, an ultraviolet detector was used for on-line monitoring with a wavelength of 300nm. According to the chromatogram, fractions with an elut...

Embodiment 3

[0022] 1. Adjust the pH of the fermented liquid containing neomocontin to 4 for acid precipitation treatment, leach after filtration, centrifuge, add activated carbon for decolorization to obtain a colorless filtrate;

[0023] 2. Homogenize the 75μm silica gel with isopropanol, put it into a dynamic axial compression column, the column packing pressure is 10Mpa, and the column packing size is Φ300×250mm;

[0024] 3. Concentrate and dry the colorless filtrate obtained in step 1, add chloroform / methanol mixture (1:4.5 by volume) to dissolve the sample liquid, pump it into a dynamic axial compression column to prepare a chromatographic system, and use chloroform / methanol / water mixed solution for elution, the volume ratio of the eluent is 81 / 18 / 2, and the sample loading is 0.3 times the weight of the loaded silica gel. During the elution process, an ultraviolet detector was used for on-line monitoring with a wavelength of 290nm. According to the chromatogram, fractions with an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com