Chemical crosslinked polyethylene insulating plastic for submarine cable

A technology of polyethylene insulation and chemical cross-linking, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of large fluctuations in the quality of final products, easy uneven distribution, and large molecular weight, etc., to improve the continuous running time , Improve the anti-scorch property, improve the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

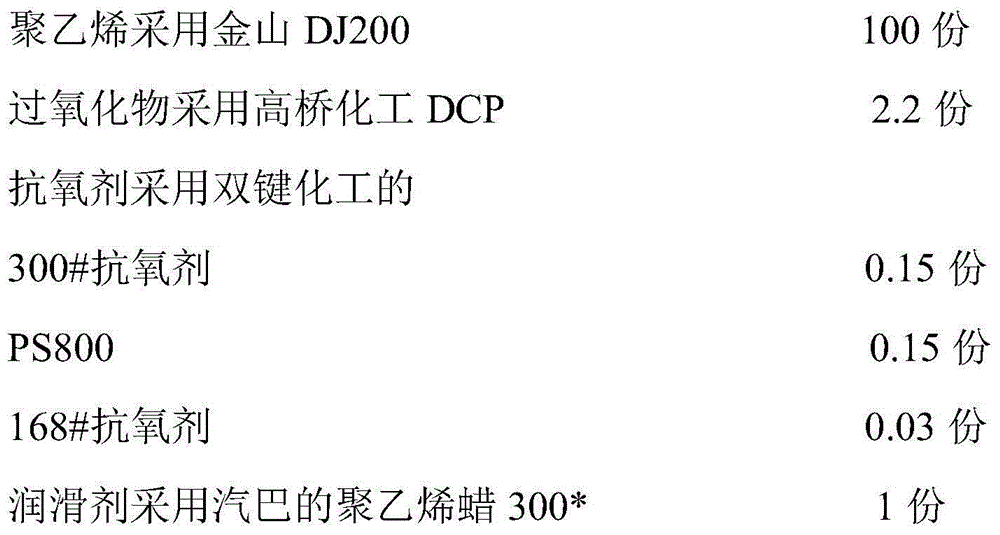

Embodiment 1

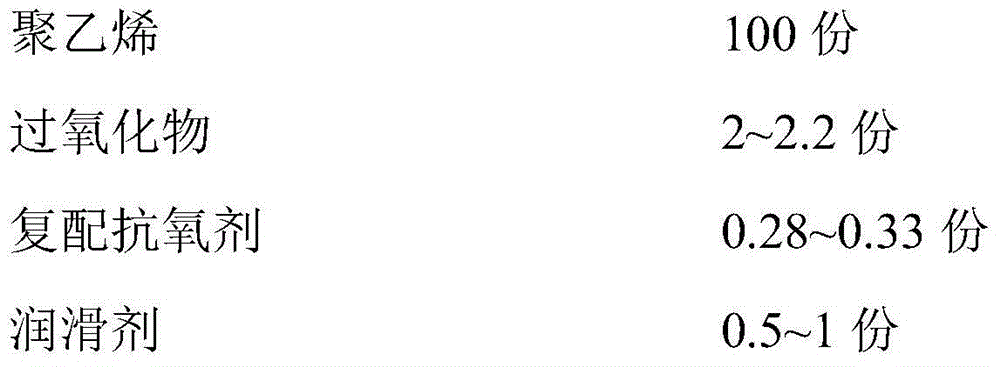

[0023] Formula: (parts by weight)

[0024]

[0025] The peroxide adopts the chemical name of Takahashi Chemical DCP as dicumyl peroxide;

[0026] The chemical name of 300# antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol;

[0027] The chemical name of PS800 is dodecyl thiodipropionate;

[0028] The chemical name of 168# antioxidant is tris[2.4-di-tert-butylphenyl] phosphite;

[0029] Preparation:

[0030] After measuring each component, put them into a 300L vacuum drum preheated at 70°C, stir and mix at a speed of 5 rpm, and take a sample after 60 minutes.

[0031] Detection method:

[0032] The samples were prepared by the molding method. The sample preparation conditions were 180°C, 15min, and the pressure of the hydraulic press was greater than 15Mpa. In terms of dynamic crosslinking speed, the samples were compared and tested under the conditions of 150°C and 30 rpm in a Haka rheometer.

[0033] The prepared samples were tested using the material standards i...

Embodiment 2

[0038] Formula: (parts by weight)

[0039]

[0040] Preparation method is with embodiment 1, detection method:

[0041] The samples were prepared by the molding method. The sample preparation conditions were 180°C, 15min, and the pressure of the hydraulic press was greater than 15Mpa. In terms of dynamic crosslinking speed, the samples were compared and tested under the conditions of 150°C and 30 rpm in a Haka rheometer.

[0042] The prepared samples were tested using the material standards in GB / T12706, and the results are as follows:

[0043]

[0044] From the test data, the products made by the present invention and the process are comparable in mechanical properties and electrical properties to the products of the same raw material melt granulation method, but there is a large change in the dynamic crosslinking rate, which can delay 50% of the dynamic crosslinking rate. The rate of crosslinking can greatly reduce the frequency of downtime in the cabling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com