Environmental-friendly TPE

An environmentally friendly and compositional technology, applied in the production and processing of polymer modified materials, can solve the problems of adverse effects of sustainable development, non-recyclable reuse, environmental pollution, etc., and achieve high plasticity, convenient production, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

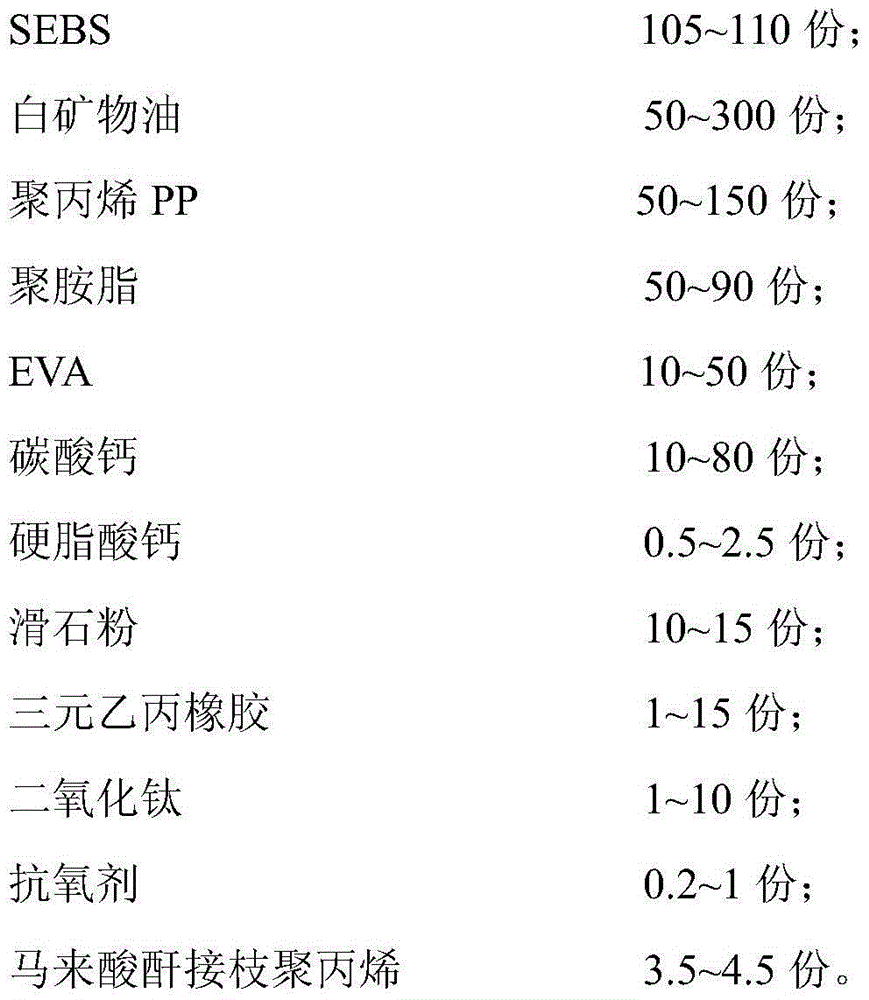

[0025] A kind of environment-friendly TPE, its composition and parts by weight are as follows:

[0026]

[0027]

[0028] The preparation method of environment-friendly TPE as mentioned above, the steps are as follows:

[0029] ⑴ Pour SEBS into the mixer;

[0030] ⑵ Pour the white mineral oil into the blender, stir for 10-15 minutes, and stir evenly;

[0031] (3) Pour the rest of the other raw materials into the blender together, and stir for another 10-15 minutes to obtain a well-stirred raw material mixture;

[0032] (4) Pour the evenly stirred raw material mixture into a twin-screw extruder, melt and extrude at 150-200°C, cool, and granulate to obtain an environmentally friendly TPE.

Embodiment 2

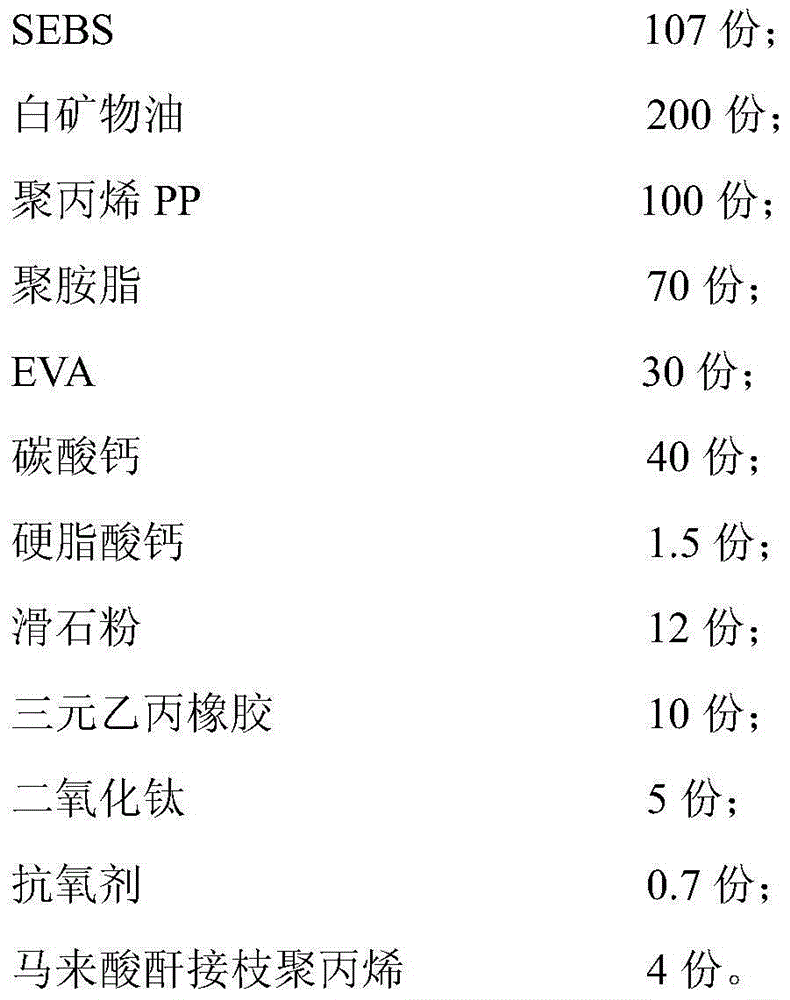

[0034] A kind of environment-friendly TPE, its composition and parts by weight are as follows:

[0035]

[0036]

[0037] The preparation method of the above-mentioned environment-friendly TPE is the same as in Example 1.

Embodiment 3

[0039] A kind of environment-friendly TPE, its composition and parts by weight are as follows:

[0040]

[0041] The preparation method of the above-mentioned environment-friendly TPE is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com