Sulfur emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and sulfur, which is applied in climate change adaptation, building components, building insulation materials, etc., can solve the problems of poor anti-rutting and water damage resistance, low strength of sulfur-emulsified asphalt mixture, and failure to achieve hot-mix asphalt mixture and other problems, to achieve the effect of improving high temperature stability and anti-rutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

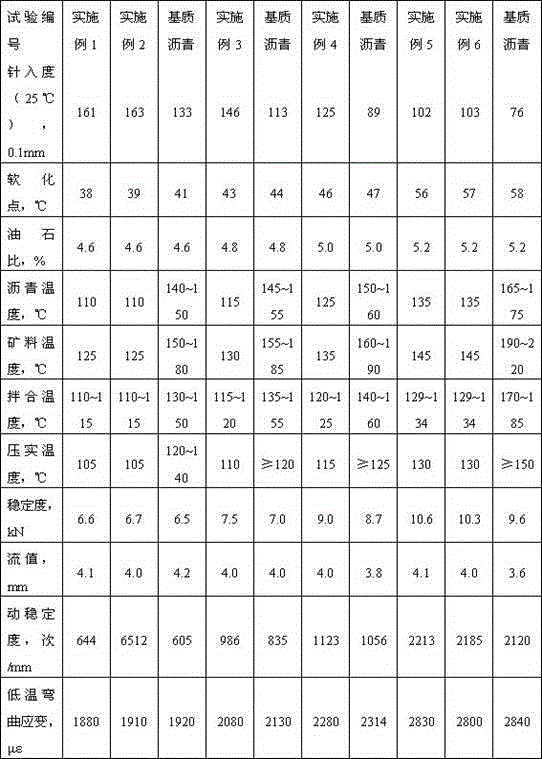

[0022] 500g of No. 130 B-grade asphalt mixed with certain road asphalt, petroleum residue and coal tar pitch, with a penetration of 138 (0.1mm) and a softening point of 41°C, heated in an oven at 110°C for 4 hours, then moved to the same temperature, Heating and stirring in the heating mantle with stirring device; 5.4g glycerol monostearate, 3.2g ethylene glycol fatty acid ester and 2.2g carbon black mixture are added in the base asphalt and stir evenly, adopt titration method to mix 27g Water is added to the base asphalt mixed with emulsifier at a rate of 800-4000 drops / min and stirred evenly to form water-in-oil emulsified asphalt. Then add 20g of sulfur powder into the water-in-oil emulsified asphalt at 90°C and mix for 20 minutes to form sulfur emulsified asphalt. The stirring speed mentioned in the above process is 500 rpm, and the properties of the sulfur emulsified asphalt are shown in Table 1.

Embodiment 2

[0024] 500g of No. 130 B-grade asphalt mixed with certain road asphalt, petroleum residue and coal tar pitch, with a penetration of 138 (0.1mm) and a softening point of 41°C, heated in an oven at 110°C for 4 hours, then moved to the same temperature, Heat and stir in a heating mantle with a stirring device, add the mixture of 5.4g sorbitan trioleate, 3.2g propylene glycol fatty acid ester and 2.2g carbon black to the base asphalt and stir evenly. Spray 27g of water intermittently into the base asphalt mixed with emulsifier in the form of small droplets in the pipe with a nozzle and stir evenly. Spray in 2 times on average with an interval of 10 minutes between each time. After fully stirring, the oil is formed. For water-in-oil emulsified asphalt, add 20g of sulfur powder to water-in-oil emulsified asphalt at 95°C and mix for 30 minutes to form sulfur emulsified asphalt. The stirring speed in the above process is 600 rpm. The properties of sulfur emulsified asphalt are shown i...

Embodiment 3

[0026] 500g of No. 110 grade B asphalt mixed with certain road asphalt, petroleum residue oil and coal tar pitch, with a penetration of 113 (0.1mm) and a softening point of 44°C, heated in an oven at 120°C for 4 hours, then moved to the same temperature, Heat and stir in a heating mantle with a stirring device, mix 5.2g polyoxyethylene sorbitan beeswax derivative, 4.3g propylene glycol fatty acid ester, 3.5g sorbitan tristearate, 2.6g glycerol monostearate Add the mixture of ethylene glycol fatty acid ester and 1.7g ethylene glycol fatty acid ester into the base asphalt and stir evenly. Use the titration method to add 58g of water into the base asphalt mixed with emulsifier at a rate of 500~2000 drops / min and stir evenly. Stir fully to form water-in-oil emulsified asphalt, then add 50g of sulfur powder to the water-in-oil emulsified asphalt at 100°C and mix for 40 minutes to form sulfur emulsified asphalt. The stirring speed described in the above process is 400 rpm, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com