Heat-reflecting thermal insulation coating and chemical product storage tank

A heat-insulating coating and heat-reflecting technology, used in reflective/signal coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of wasting manpower, material and financial resources, unfavorable for safe and stable production, and the coating is difficult to resist water erosion. , to protect human health, save water and energy, and improve thermal corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

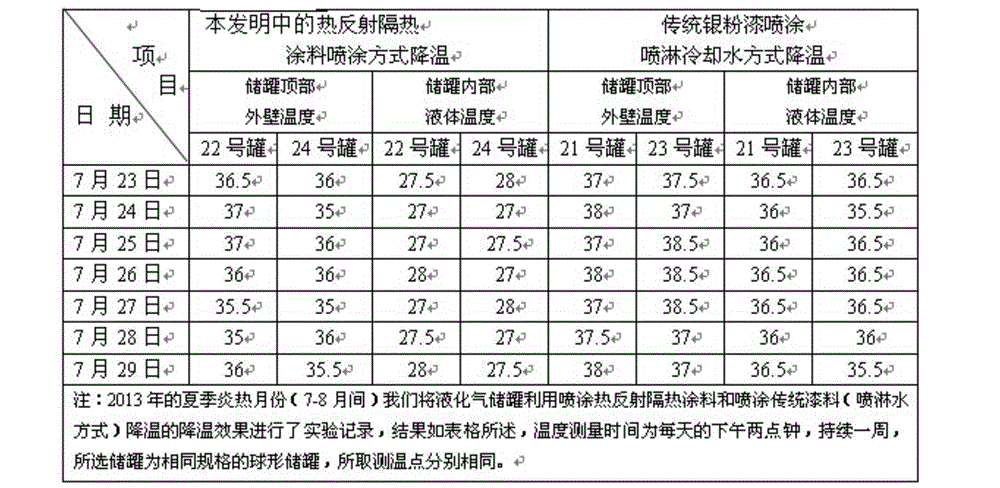

Examples

Embodiment 1

[0035] Heat reflective insulation coatings, including primers, intermediate coats and top coats.

[0036] The primer composition and parts by weight are 20 parts of SH-023 organosilicon modified epoxy resin, 15 parts of butyl acetate, 4 parts of hollow glass microspheres, 3 parts of nano-titanium dioxide, 3 parts of zinc powder, and red iron oxide 5 parts, 4 parts of mica iron oxide, 2 parts of 593 modified amine curing agent, 1.5 parts of NXZ defoamer, 2 parts of hydroxyethyl cellulose thickener QP09L.

[0037] The composition of the intermediate paint and its parts by weight are 15 parts of Emerald 665 organosilicon modified epoxy resin, 10 parts of SH-024 organosilicon modified epoxy resin, 12 parts of ceramic hollow microspheres, and 15 parts of hollow glass microspheres , 5 parts of nano titanium dioxide, 3 parts of 593 modified amine curing agent, 0.5 part of CR-733S halogen-free flame retardant, 1 part of flame retardant TBC, 0.5 part of DCA-406 silicone defoamer.

[0...

Embodiment 2

[0040] Heat reflective insulation coatings, including primers, intermediate coats and top coats.

[0041] The primer composition and parts by weight are 16 parts of SH-024 organosilicon modified epoxy resin, 22 parts of butyl acetate, 6 parts of hollow glass microspheres, 5 parts of nano-titanium dioxide, 6 parts of zinc powder, iron oxide red 3 parts, 8 parts of mica iron oxide, 2.3 parts of 593 modified amine curing agent, 1.7 parts of NXZ defoamer, and 1.6 parts of thickener QP09L.

[0042] The composition of the intermediate paint and its parts by weight are 12 parts of Emerald 665 organosilicon modified epoxy resin, 15 parts of SH-024 organosilicon modified epoxy resin, 11 parts of ceramic hollow microspheres, and 11.5 parts of hollow glass microspheres , 7 parts of nano titanium dioxide, 2.4 parts of 593 modified amine curing agent, 1.0 part of CR-733S halogen-free flame retardant, 1.2 parts of flame retardant TBC, 0.7 parts of DCA-403 silicone defoamer.

[0043] The comp...

Embodiment 3

[0045] Heat reflective insulation coatings, including primers, intermediate coats and top coats.

[0046] The primer composition and parts by weight are 18 parts of SH-024 organosilicon modified epoxy resin, 18 parts of butyl acetate, 5 parts of hollow glass microspheres, 7 parts of nano-titanium dioxide, 4 parts of zinc powder, and red iron oxide 7 parts, 6 parts of mica iron oxide, 1.8 parts of 593 modified amine curing agent, 2.0 parts of NXZ defoamer, and 1.5 parts of thickener QP09L.

[0047] The composition of the intermediate paint and its parts by weight are 14 parts of Emerald 665 organosilicon modified epoxy resin, 11.5 parts of SH-024 organosilicon modified epoxy resin, 14 parts of ceramic hollow microspheres, and 12 parts of hollow glass microspheres , 6 parts of nano titanium dioxide, 2.6 parts of 593 modified amine curing agent, 0.8 parts of CR-733S halogen-free flame retardant, 1.6 parts of flame retardant TBC, 0.6 parts of DCA-425w silicone defoamer.

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com