Car lamp shade with anti-fog function and manufacturing method thereof

A technology for car lamp shades and lamp shades, which is applied in the direction of lamp shades, headlights, motor vehicles, etc., can solve the problems that cannot fundamentally solve the problem of car lamp fogging, affect the life and appearance of car lights, and reduce the lighting effect of car lights, and achieve Good super-hydrophobic properties, simple structure, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

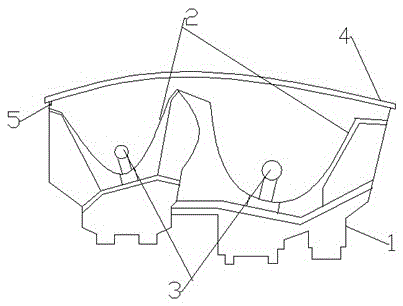

[0018] see figure 1 , the car lights generally include a rear cover, a lampshade 4, a reflector 2 and a bulb 3, the rear cover (not shown in the figure) and the lampshade 4 form a closed cavity, and the reflector 2 and the bulb 3 are sealed in the cavity, The light emitted by the bulb 3 is reflected to the lampshade 4 by the reflector 2 .

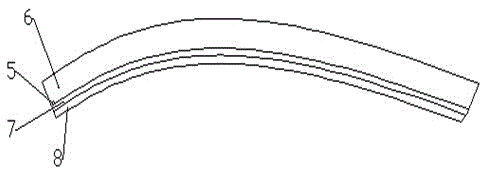

[0019] see you again figure 2 The lampshade 4 is composed of a lampshade body 6, a power interface 5, a transparent conductive film 7 and a transparent hydrophobic film 8. The outermost layer of the lampshade 4 is the lampshade body 6, and a layer of transparent conductive film 7 is closely attached to the inner surface of the lampshade body 6. , on the inner surface of the transparent conductive film 7, a layer of transparent hydrophobic film 8 is tightly adhered. A power supply interface 5 is fixed on one side of the lampshade body 6, and the transparent conductive film 7 is connected with the vehicle-mounted power supply through the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com