Monochromator for microplate readers

A technology of microplate reader and monochromator, which is applied in the field of optical colorimetric analysis, can solve the problems that the uniformity of light energy distribution and the flexibility of control cannot be guaranteed, the detection requirements cannot be met, and there are many integral parts, and the structure is compact. , Small size, reliable instrument effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

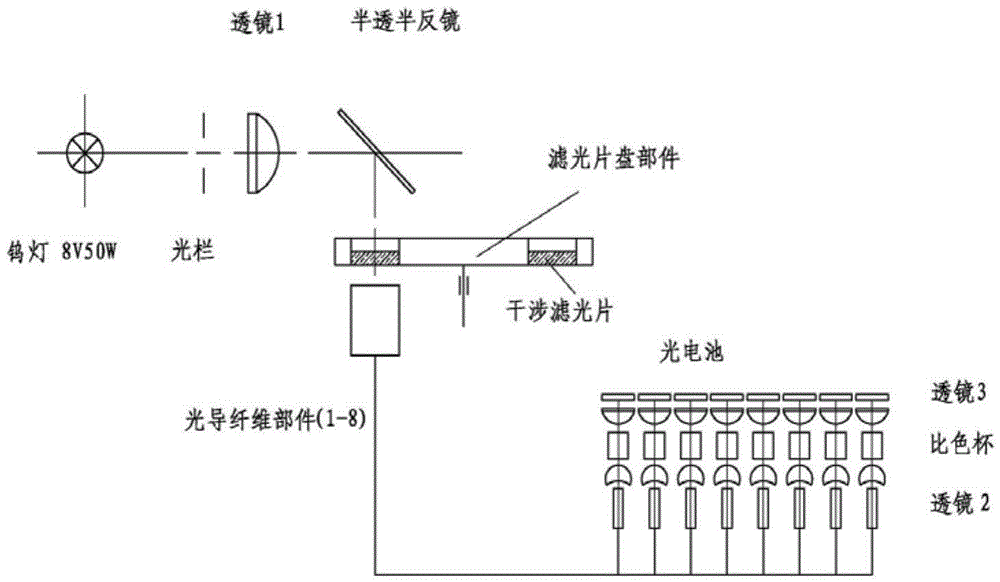

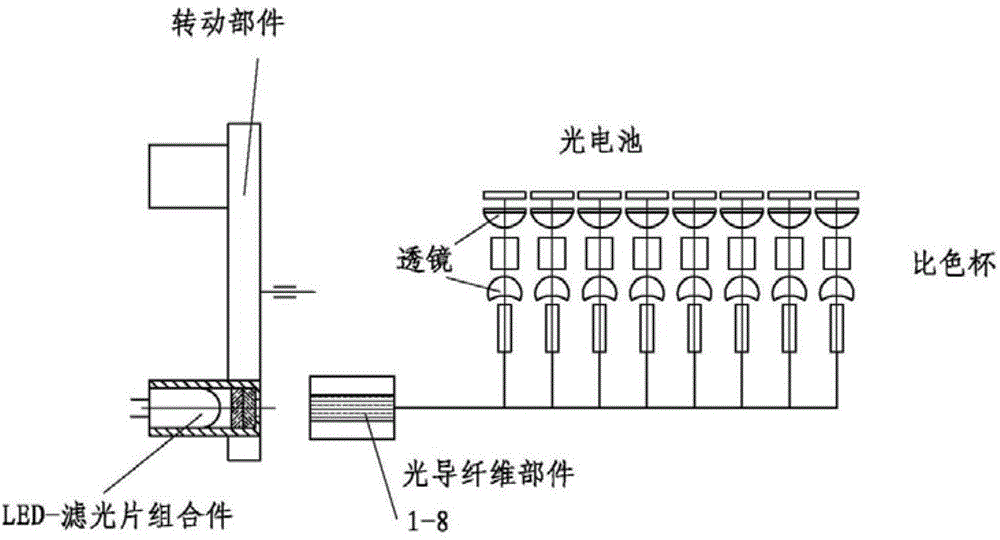

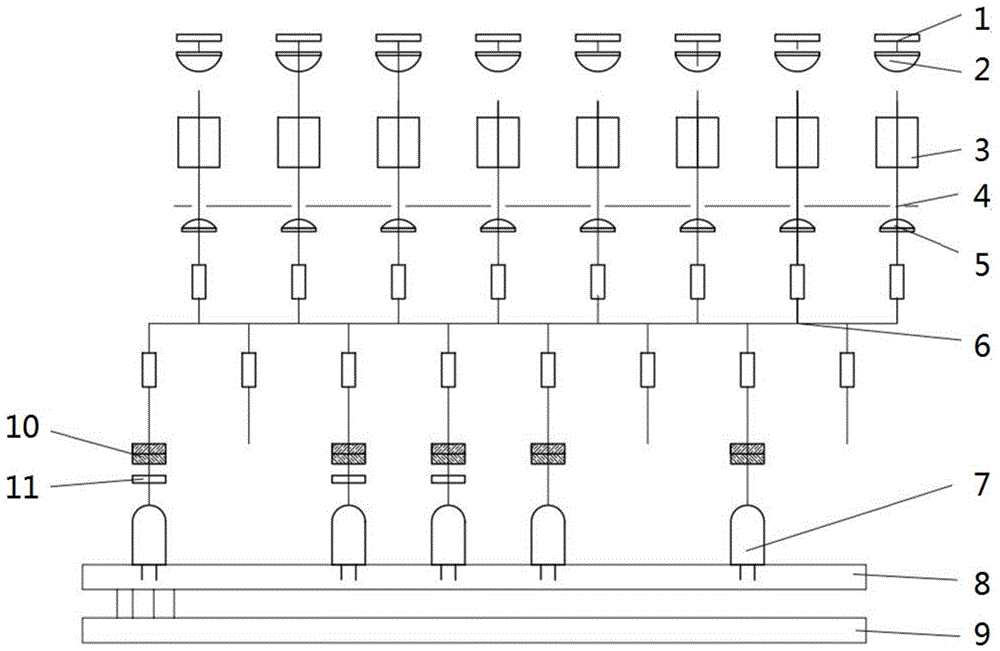

[0025] Such as image 3 and Figure 4 As shown, this embodiment includes: several monochromatic light components 1 and optical fiber components 2, wherein: the optical fiber component 2 divides the monochromatic light generated by each monochromatic light component 1 into several beams to focus on the colorimetric colorimeter of the corresponding microplate reader In the center of the cup, the light is concentrated on the photocell through the lens to realize the conversion of optical signal to electrical signal.

[0026] Such as Figure 6 As shown, the present embodiment takes eight light inlet ports and eight light outlet ports as an example: when any LED is turned on, the monochromatic light passes through the color filter assembly, and then shoots to the corresponding light inlet port of the optical fiber. The optical fiber component splits the beam, and emits eight beams of monochromatic light at the light outlet of the optical fiber component. After being focused by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com