Bilateral Dislocation Differential Confocal Measurement Method

A differential confocal and measurement method technology, applied in the direction of testing optical performance, etc., can solve the problems of improving the resolution ability and other problems, and achieve the effect of improving the signal-to-noise ratio, improving the axial resolution ability, and high signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

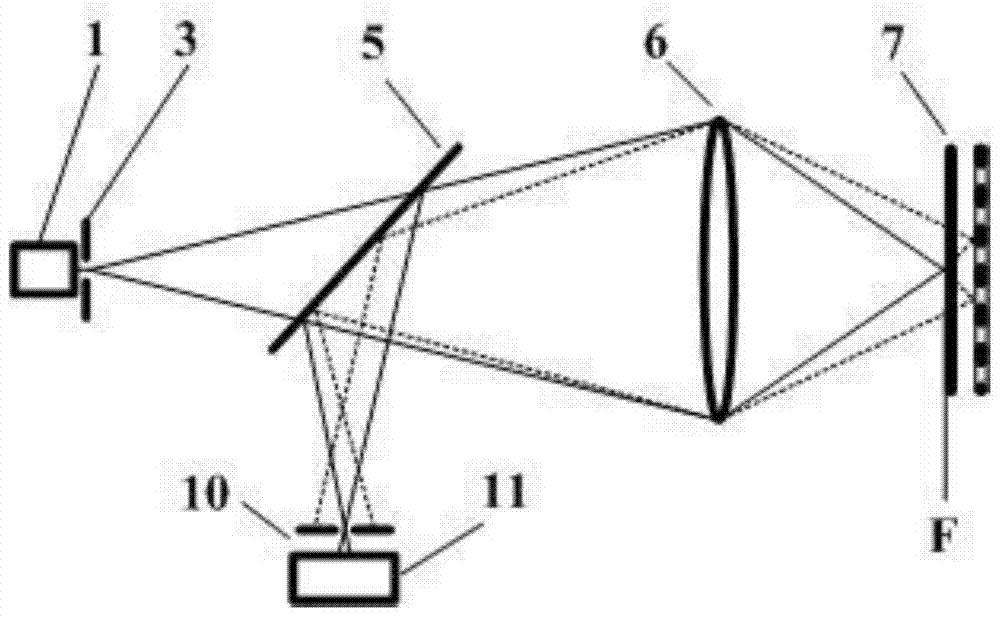

[0062] The specific steps of using the method of the present invention for fitting and measuring the height value of a single point are combined image 3 described as follows:

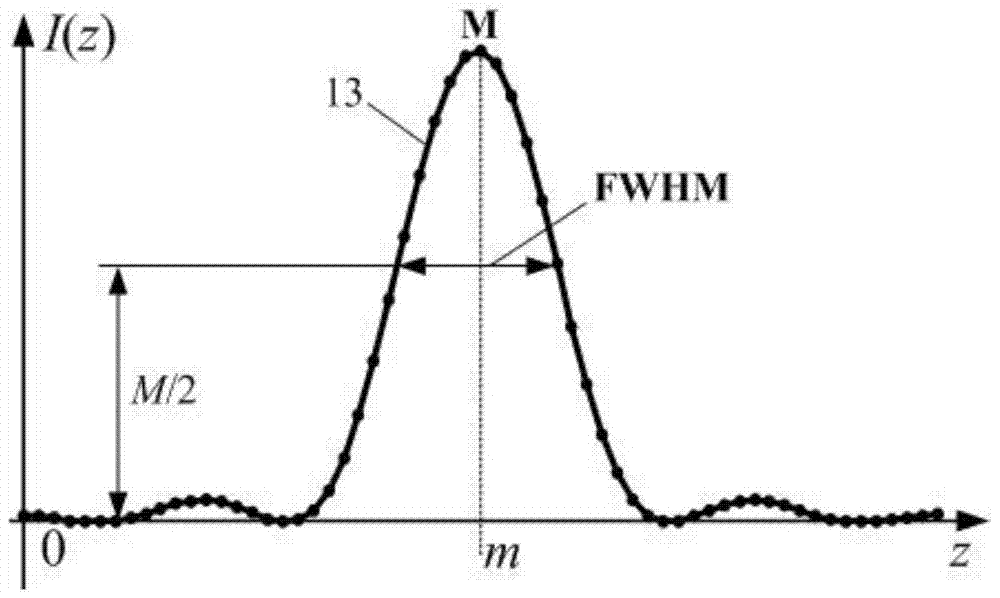

[0063] Step 1. Select a certain measurement point N(x,y) on the sample 7, make the objective lens 6 focus the spot to scan the measurement point axially, and at the same time, the photodetector 11 detects the confocal axial intensity of the sample axial position. The response value is 14, denoted as I(z), where x, y and z are the coordinates of the horizontal position and the axial height position of the sample measurement point, respectively;

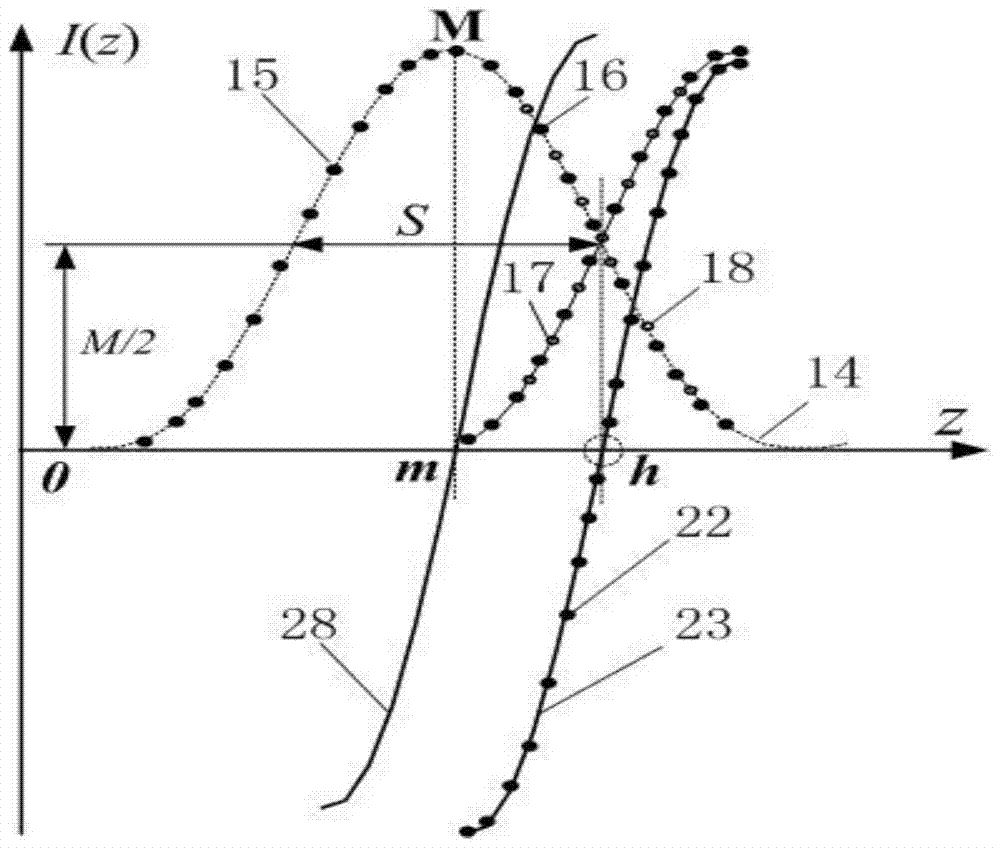

[0064] Step two, as image 3 As shown, determine the maximum value M of the confocal axial intensity response value 14, and divide the confocal axial intensity response value 14 into a left side data group 15 and a right side data group 16 with M as a boundary;

[0065] Step three, as image 3 As shown, the right side data group 16 does not move, so that the...

Embodiment 2

[0071] Under the scanning of the sample workbench, the method of the present invention is used to combine the measurement steps of point-by-point tomographic scanning imaging. Image 6 described as follows:

[0072] Step 1. Move the worktable 8 and record the horizontal position coordinates N(x, y) of the measured point of the sample 7;

[0073] In step 2, the objective lens 6 is fed in an axial step relative to the sample 7 along the optical axis direction, and the photodetector 11 measures the confocal axial intensity response value 14 corresponding to each axial feeding position;

[0074] Step three, as Figure 5 As shown, for each confocal axial intensity response value 14 obtained in step 2, the shifted confocal axial intensity response value 24 is obtained by translating S along the lateral coordinate, and the S value is selected as the confocal axial intensity response data set 14 half-height width FWHM of the curve;

[0075] Step four, as Figure 5 As shown in step...

Embodiment 3

[0083] Under the scanning of the sample workbench, the method of the present invention is used to combine the measurement steps of layer-by-layer scanning tomography. Image 6 described as follows:

[0084] Step 1. Focus the objective lens 6 on the first interface of the sample to be measured, and then move the worktable 8. In this interface, the photodetector 11 measures the photoelectric signal values of all the points to be measured, and records the level of all the points to be measured. Position coordinates;

[0085] Step 2: According to the sample measurement accuracy requirements, select the micro-feed step distance of the objective lens relative to the sample;

[0086] Step 3: Make the objective lens 6 carry out micro-step feeding relative to the sample 7 along the optical axis direction, and then move the worktable 8 precisely according to the coordinates of the horizontal position point recorded in the step 1, so that the focusing spot of the objective lens is ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com