Method for preparing graphene oxide sensor

A sensor and graphene technology, applied in instruments, scientific instruments, measuring devices, etc., to achieve the effects of convenient measurement, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

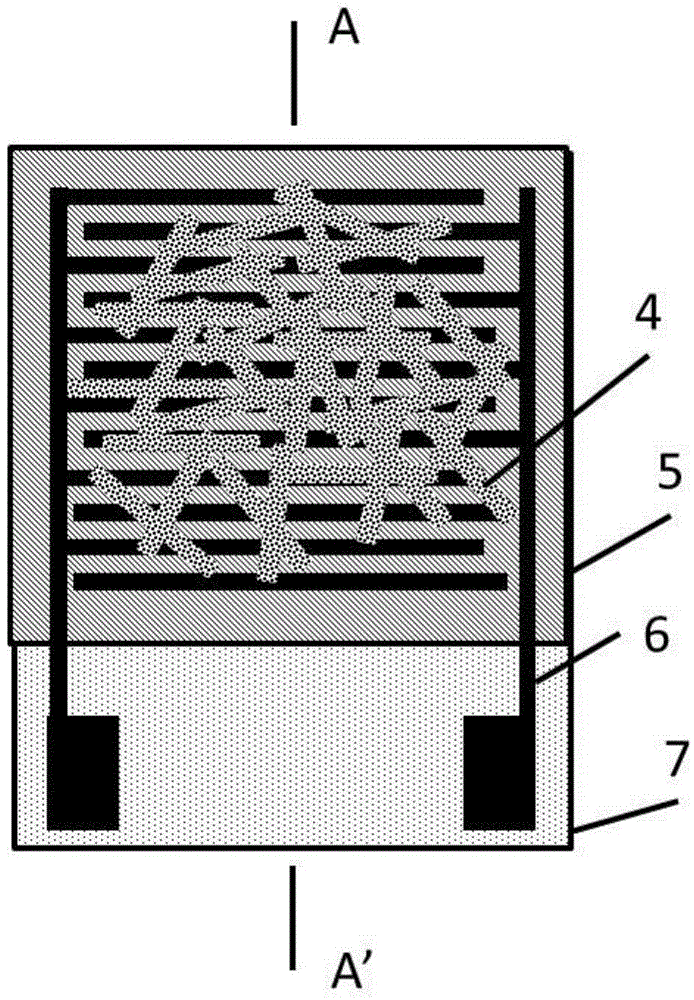

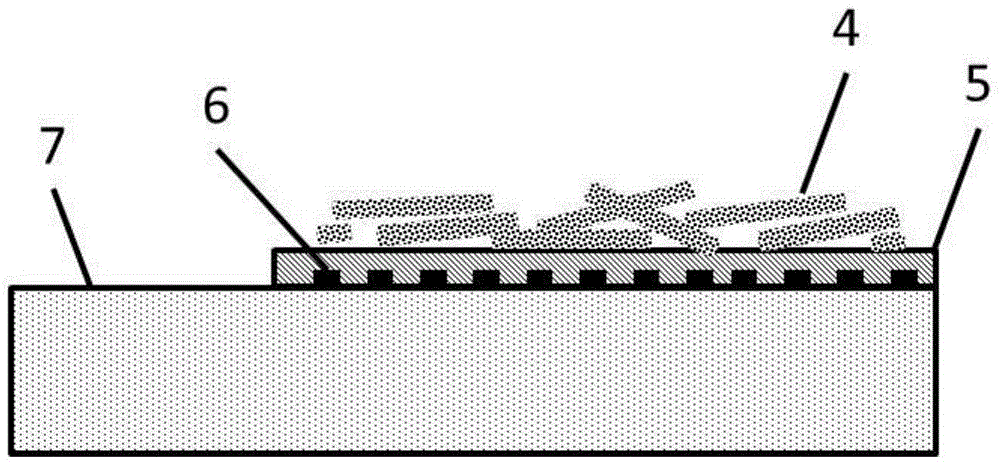

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

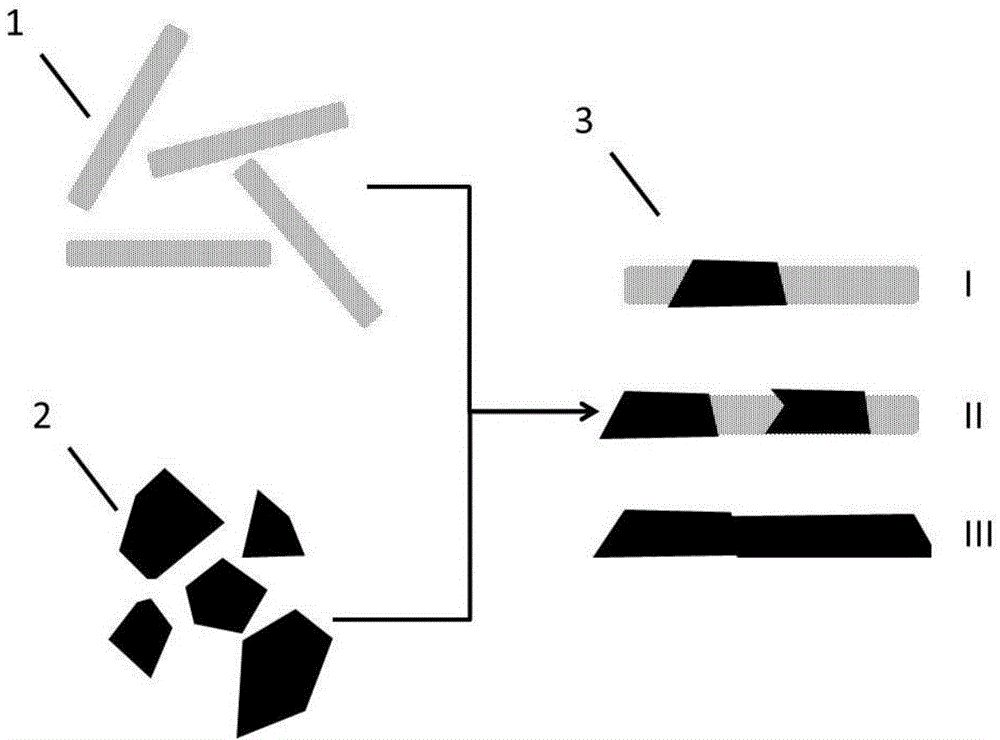

[0031] A kind of method for preparing graphene oxide sensor, concrete steps are as follows:

[0032] (1) Disperse 0.2 mg of graphene oxide with a sheet number of 10 layers and a sheet size of 45 microns in 10 ml of water to form a stable graphene oxide dispersion; wherein: water can be replaced by water, ethanol, benzene , toluene, cyclohexane, dimethyl sulfoxide, cyclopentanone, cyclohexanone, and chloroform, or the combination of two or more has no effect on the results of this experiment. During actual preparation, the number of graphene oxide sheets can be 1-20 layers, and the sheet size is less than 50 microns.

[0033] (2) Carry out surface functionalization treatment to the gold nanowire material that diameter is 0.8 micron, length is 45 micron, processing method is as follows: add thioglycolic acid in gold nanowire dispersion liquid, carry out thorough stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com