Preparation method of lithium metaaluminate porous microspheres as solid tritium multiplication agent

A technology of lithium metaaluminate and porous microspheres, which is applied in the direction of reducing greenhouse gases, nuclear reactors, and nuclear power generation. It can solve problems such as complex processes and achieve the effects of simple processes, good tritium release performance, and delayed hydrolysis and polycondensation rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of preparation method of lithium metaaluminate porous microsphere, carries out following steps successively:

[0038] 1), 4g (0.011mol) sodium dodecylbenzenesulfonate and 8g OP-10 (hydrophilic, hydroxyl value 87±10) were dissolved in 300g deionized water, and stirred at 500r / min for 60min to obtain a mixed solution A ;

[0039]2) Dissolve 1.829g (0.018mol) of acetylacetone and 4.545g (0.018mol) of aluminum sec-butoxide in 16.950g of isopropanol, and stir at a speed of 500r / min for 60min to obtain a mixed solution B 1 ;

[0040] 3), the mixed solution B obtained in step 2) 1 Add 1.247g (0.018mol) lithium nitrate to , and keep stirring for 90min to obtain a clear mixed solution B 2 ;

[0041] 4), add 0.571g Span80 and 1.142g (0.003mol) polyethylene glycol to the mixed solution B 2 , and continued to stir for 60min, and finally obtained a clear and uniform mixed solution B 3 ;

[0042] 5), add the mixed solution A obtained in step 1) into a high...

Embodiment 2

[0045] Embodiment 2, change "4g sodium dodecylbenzenesulfonate and 8g OP-10" in embodiment 1 into "12g sodium dodecylbenzenesulfonate", and the rest are the same as embodiment 1.

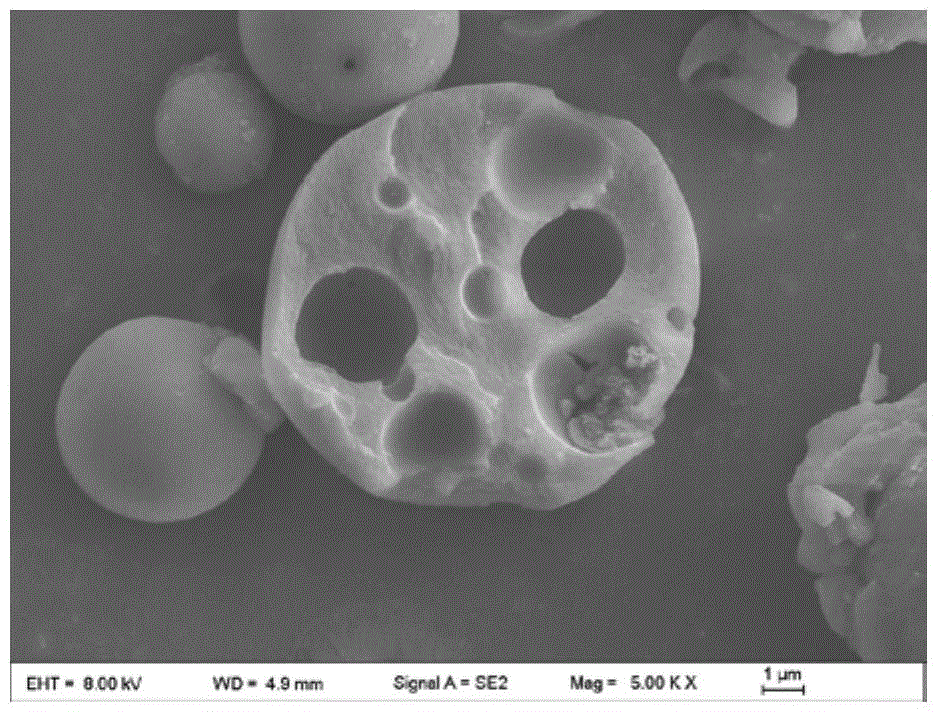

[0046] The size of the obtained lithium metaaluminate porous microsphere is 1-3 μm, the inside of the microsphere is a closed pore structure, and the diameter of the closed pore is 400nm-700nm. The specific surface area is 98m 2 / g, the purity is 88%.

Embodiment 3

[0047] Example 3. Change "1.829g acetylacetone" in Example 1 to "2.377g ethyl acetoacetate", and change the heat treatment temperature from 1000°C to 1300°C; the rest are the same as in Example 1.

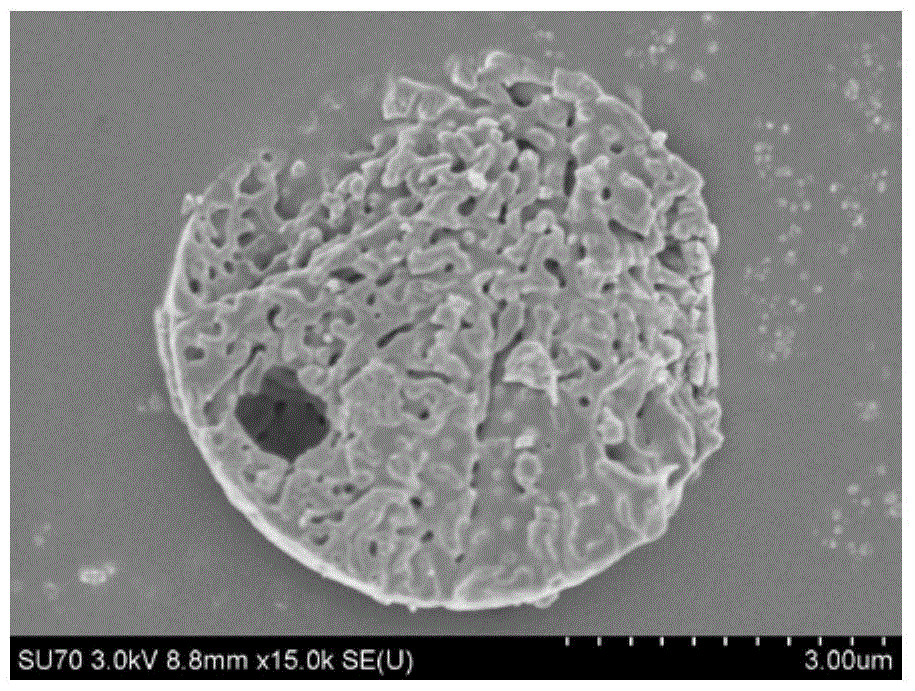

[0048] The size of the obtained lithium metaaluminate porous microsphere is 2-4 μm, and the inside of the microsphere is a closed pore structure, and the diameter of the closed pore is 500nm-800nm. The specific surface area is 105m 2 / g, the purity is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com