A modified zeolite and its composite adsorbent and its use

A technology of modified zeolite and composite adsorption, which is applied in the directions of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, fauhhedral crystalline aluminosilicate zeolite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as specific limitations on the present invention.

[0094] 1 Preparation of experimental materials

[0095] 1.1 Humidification pretreatment of zeolite

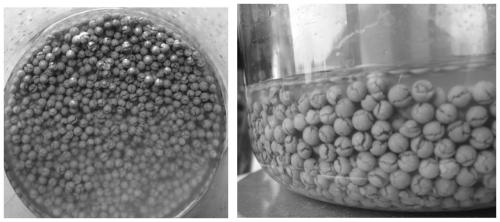

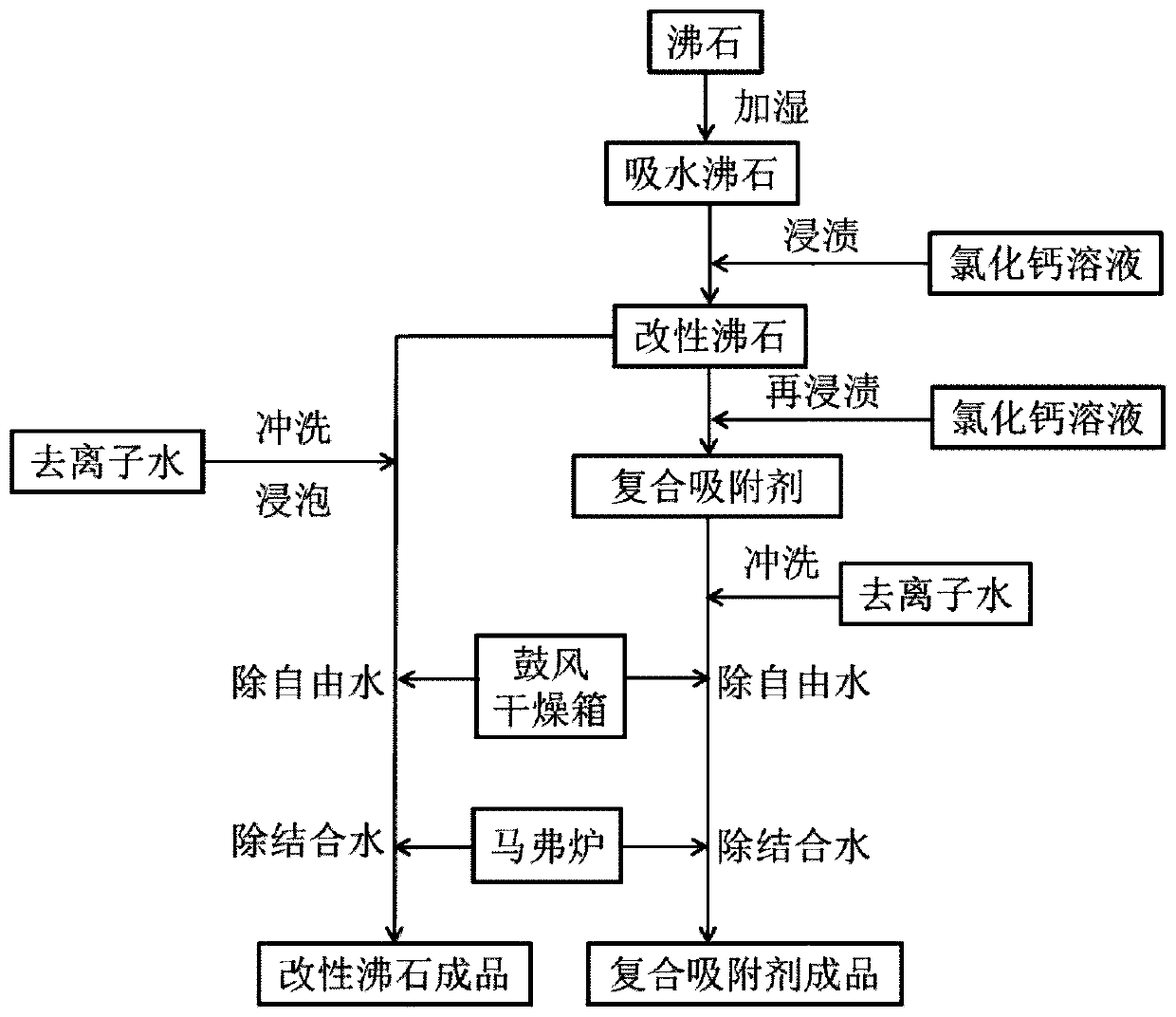

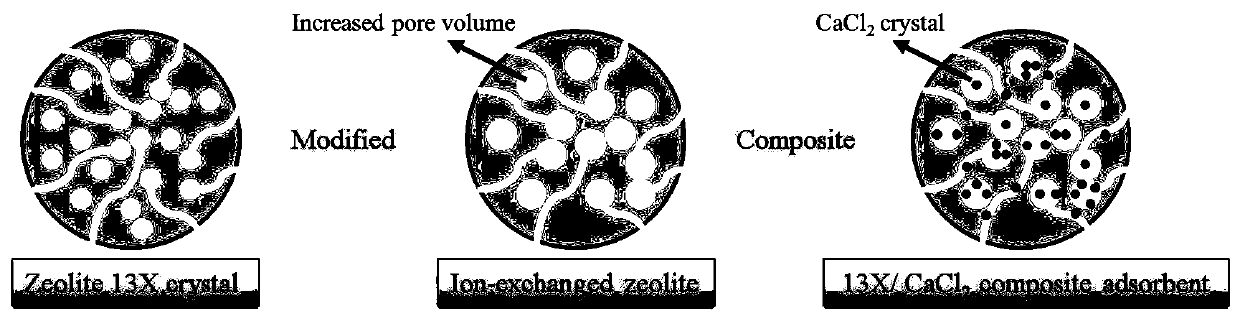

[0096] In the preparation process of preparing silica gel-metal chloride composite adsorbent, the phenomenon of skeleton rupture will occur when silica gel particles are immersed in calcium chloride solution. Similarly, when zeolite, such as 13X type zeolite, is immersed in calcium chloride solution , there will also be a phenomenon of zeolite framework rupture, such as figure 1 As shown, the main reason for the cracking is that when the zeolite with low water content contacts with the calcium chloride solution, a large amount of heat of adsorption will be rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com