Preparation method and application of porous organic silicon microsphere

A technology of organosilicon and microspheres, applied in applications, other household utensils, ceramic products, etc., can solve the problems of explosives, low light transmittance, flammable odor, etc., and achieve high light transmittance and haze, preparation method Simple, non-toxic preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] According to a preferred embodiment of the present invention, the polysiloxane in the liquid silicone composition has a viscosity of 10 to 100,000 mm at 25°C 2 / s, preferably, the viscosity of the liquid silicone composition is 100-10000mm 2 / s, more preferably, the viscosity of the liquid silicone composition is 200-5000mm 2 / s.

[0027] The curing retarder is selected from one or more of alcohol derivatives with carbon-carbon triple bonds, enyne compounds, alkenyl-containing polysiloxanes, amide compounds and maleate compounds.

[0028] Preferably, the curing retardant is selected from 3-methyl-1-butyn-3-ol, 3,5-dimethyl-1-hexyn-3-ol, 3-phenyl-1-butyne -3-alcohol, 1-ethyne-1-cyclohexanol, 3-methyl-3-pentene-1-yne, 3,5-dimethyl-3-hexene-1-yne, polyvinyl poly Siloxane, N,N-diallyl formamide, N,N-diallyl benzamide, monoethyl maleate, monoallyl maleate, mono-2-ethyl maleate One or more of hexyl ester and diallyl maleate;

[0029] More preferably, the curing retarder ...

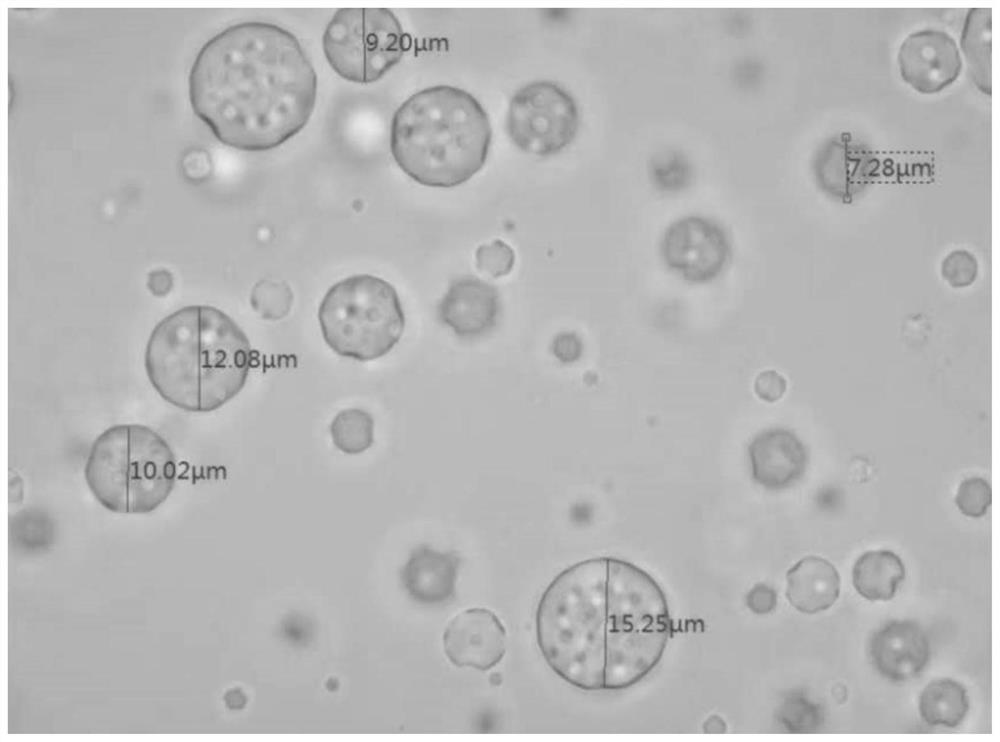

Embodiment 1

[0123] The viscosity at 25°C of 98 parts by weight is 1500mm 2 Vinyl content per s 0.6wt% vinyl silicone oil (V-1500 type), 2 parts by weight at 25°C, the viscosity is 350 mm 2 The hydrogen content of / s is 1.2wt% hydrogen-containing silicone oil (H-350 type), 2.0 parts by weight structure is (CH 2 =CH) 3 -SiO-(Si-(CH 3 )(CH=CH 2 )O) 8 -Si(CH=CH 2 ) 3 The curing retarder and 0.25 parts by weight of Platinum content 3000ppm Carl's catalyst are mixed homogeneously, then add 4.00 parts by weight of sorbitan monostearate (Span-60) of HLB value 4.7 and mix homogeneously, then add 30 parts by weight Parts of water and emulsified into water-in-oil emulsion with emulsification equipment.

[0124] 5.00 parts by weight of polyoxyethylene (20) sorbitan monostearate (Tween-60) with an HLB value of 14.9 are mixed with 100 parts by weight of water, the water-in-oil emulsion is added to the above mixed solution and mixed, and Emulsified into water-in-oil-in-water emulsion by emulsifi...

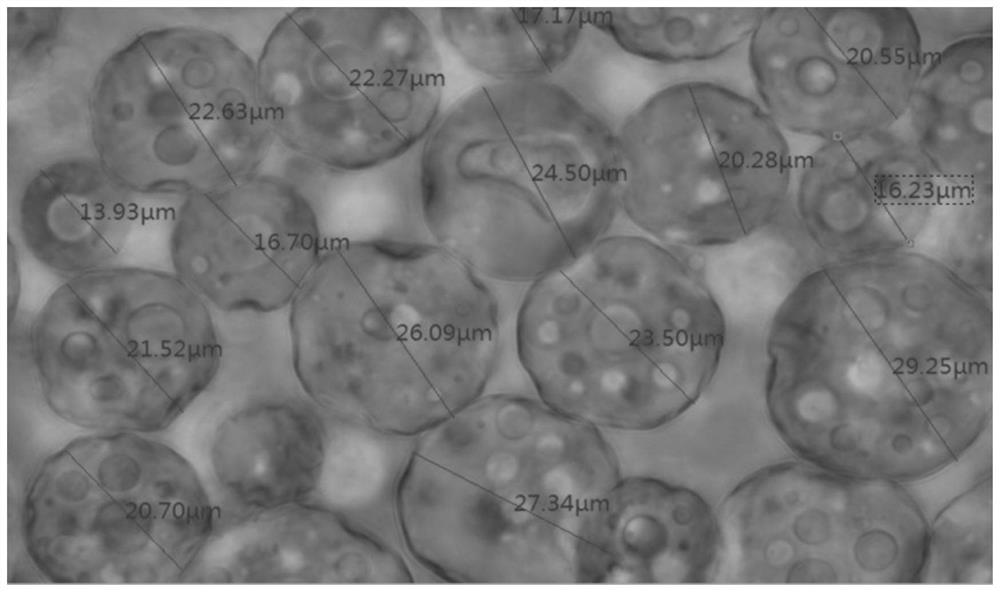

Embodiment 2

[0130] The viscosity of 90 parts by weight at 25°C is 2500mm 2 / s Vinyl silicone oil (type V-1500) with a vinyl content of 0.9wt%, 10 parts by weight at 25°C with a viscosity of 300mm 2 / s Hydrogen-containing silicone oil (H-350 type) with a hydrogen content of 0.3wt%, the structure is CH 2 =CH-Si(CH 3 ) 2 -O-(Si(CH 3 )(CH=CH 2 )O) 8 -Si(CH 3 ) 2 -CH=CH 2 4.2 parts by weight of the curing retarder and 0.19 parts by weight of the Karl's catalyst with a platinum content of 3000ppm are mixed uniformly, then 3.00 parts by weight of sorbitan monooleate (Span-80) with an HLB value of 4.3 are added and mixed uniformly, and then added 60 parts by weight of water and emulsified into water-in-oil emulsion with emulsification equipment.

[0131] Mix 6.00 parts by weight of polyoxyethylene lauryl ether (Brij35) with an HLB value of 16.9 and 80 parts by weight of water, add the water-in-oil emulsion to the mixture, and emulsify it into a water-in-oil-in-water emulsion through emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com