Neodymium iron boron magnet added with terbium powder and preparation method thereof

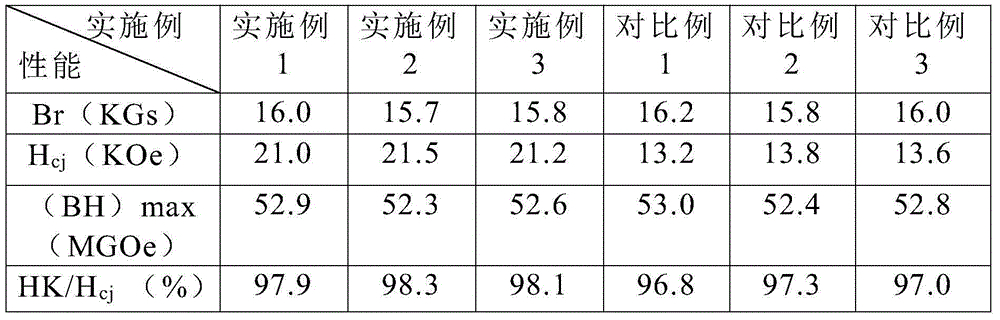

A NdFeB magnet technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of residual magnetism and magnetic energy product reduction, sintered NdFeB magnet corrosion resistance and mechanical properties are not reflected, The coercive force of NdFeB magnets is not obviously improved, and the effect of improving the coercivity, the preparation method is simple and feasible, and the coercive force and temperature stability are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

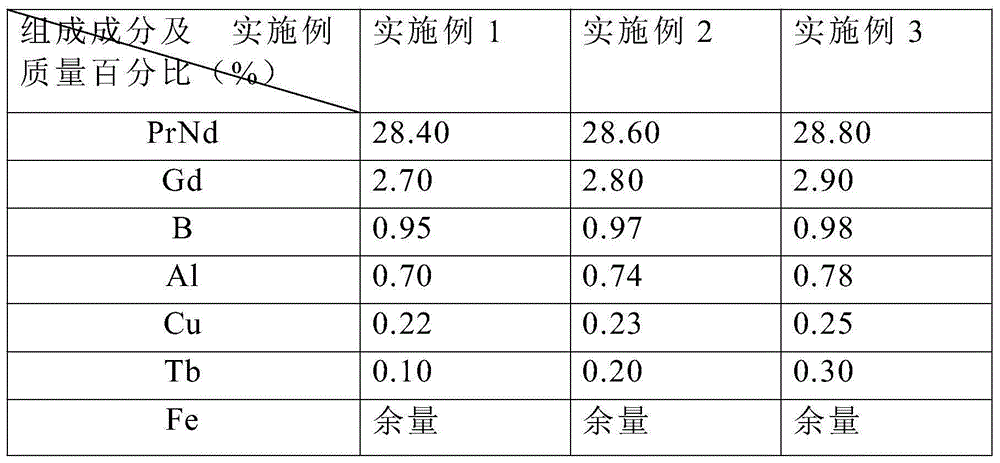

[0029] Batching and smelting: batching is carried out according to the composition and mass percentage of the NdFeB magnets described in Example 1 of Table 1, and then sent to a vacuum quick-setting melting furnace and preheated by power supply, and then vacuumed to 10 -3 PaPa, stop vacuuming and fill in high-purity argon (content ≥ 99.99%) to reach 0.045MPa and then smelt. After the furnace charge is completely melted, perform scale casting at a cooling roll speed of 2.60m / s to obtain an average thickness of 0.20mm. Strip sheet; wherein the charge is praseodymium-neodymium alloy with a Pr content of 22%-28%, gadolinium-iron alloy with a Gd content of 60%-65%, boron-iron alloy with a B content of 15%-20%, industrial aluminum ingots, Iron ingots and electrolytic copper.

[0030] Hydrogen crushing and air-jet milling treatment: the above-mentioned flakes are subjected to hydrogen crushing treatment to obtain crushed powder with an average particle size of 10.0 μm, and then Tb po...

Embodiment 2

[0035] Batching and smelting: Batching is carried out according to the composition and mass percentage of the NdFeB magnets described in Example 2 of Table 1, and then sent to the vacuum quick-setting melting furnace and preheated by power supply, and then vacuumed to 6×10 -3 Pa, stop vacuuming and fill in high-purity argon (content ≥ 99.99%) to reach 0.048MPa and then smelt. After the furnace charge is completely melted, perform scale casting at a cooling roll speed of 2.65m / s to obtain an average thickness of 0.40mm. Strip sheet; wherein the charge is praseodymium-neodymium alloy with a Pr content of 22%-28%, gadolinium-iron alloy with a Gd content of 60%-65%, boron-iron alloy with a B content of 15%-20%, industrial aluminum ingots, Iron ingots and electrolytic copper.

[0036] Hydrogen crushing and jet milling treatment: The above-mentioned flakes are subjected to hydrogen crushing treatment to obtain crushed powder with an average particle size of 11.0 μm, and then Tb powd...

Embodiment 3

[0041] Batching and smelting: batching is carried out according to the composition and mass percentage of the NdFeB magnets described in Example 3 of Table 1, and then sent to the vacuum quick-setting melting furnace and preheated by power supply, and then vacuumed to 10 -2 Pa, stop vacuuming and fill in high-purity argon (content ≥ 99.99%) to reach 0.050MPa and then smelt. After the furnace charge is completely melted, perform scale casting at a cooling roll speed of 2.70m / s to obtain an average thickness of 0.50mm. Strip sheet; wherein the charge is praseodymium-neodymium alloy with a Pr content of 22%-28%, gadolinium-iron alloy with a Gd content of 60%-65%, boron-iron alloy with a B content of 15%-20%, industrial aluminum ingots, Iron ingots and electrolytic copper.

[0042] Hydrogen crushing and air-jet milling treatment: the above-mentioned flakes were subjected to hydrogen crushing to obtain crushed powder with an average particle size of 12.0 μm, and then Tb powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com