Dysprosium oxide coated aluminum-nickel-cobalt permanent magnet material composite powder, preparation method thereof and system device

A technology of permanent magnet materials and composite powders, applied in magnetic materials, magnetic objects, transportation and packaging, etc., can solve the problems of low coercive force, easy demagnetization, easy magnetization of AlNiCo magnets, etc., and achieve the coating layer Uniform, simple method, convenient and controllable coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

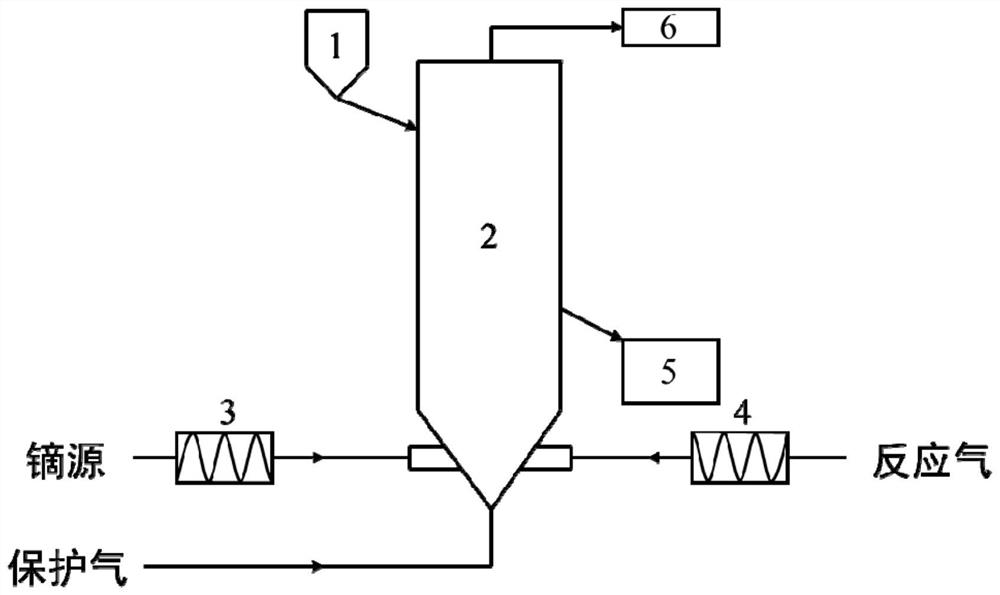

[0055] In another specific embodiment, the present invention provides a method for preparing a dysprosium oxide-coated AlNiCo permanent magnet material composite powder, the preparation method comprising:

[0056] (1) Alnico particles with a particle size of 0.5-100 μm are fluidized in a protective atmosphere to obtain fluidized Alnico particles, and the protective gas used in the protective atmosphere includes nitrogen, argon or helium At least one or a combination of two of them;

[0057] (2) Preheat the dysprosium source to 718-1500°C, mix the preheated dysprosium source with the carrier gas, and pass it into the protective atmosphere where the fluidized alnico particles are located at a gas velocity of 50-500mL / min At the same time, the reaction gas is preheated to 0 ~ 100 ° C, the preheated reaction gas is mixed with the carrier gas, and then passed into the protective atmosphere where the Alnico particles in the fluidized state are located at a gas velocity of 75 ~ 500mL...

Embodiment 1

[0060] This embodiment provides a preparation method of dysprosium oxide-coated AlNiCo magnetic material composite powder, the preparation method provided in the present invention such as figure 1 Carried out in the system device shown, described preparation method comprises the following steps:

[0061] (1) Nitrogen is introduced into the fluidized bed reaction device as a protective gas, so that the alnico particles with a particle size of 1 to 3 μm are in a fluidized state in the protective atmosphere;

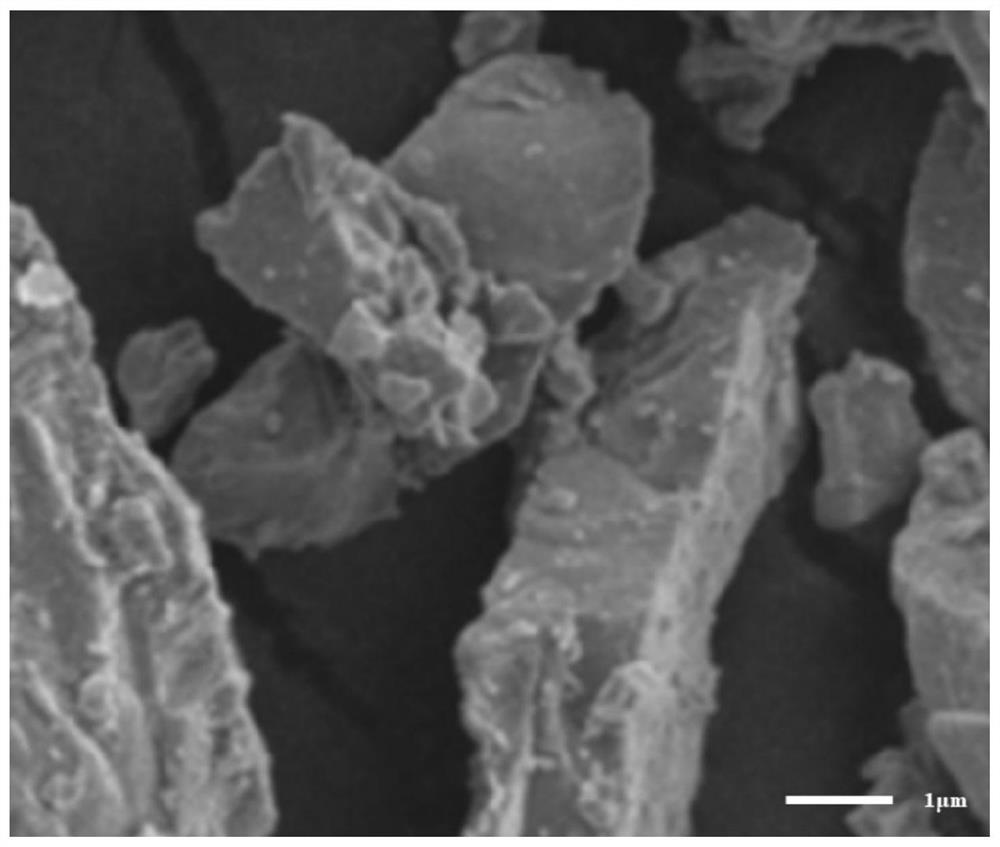

[0062] (2) the dysprosium source DyCl 3 After preheating to 800°C, the carrier gas is sent to the fluidized bed reaction device 2, and the mixed gas velocity of the dysprosium source and the carrier gas is 50mL / min; the reaction gas is preheated to 30°C and sent to the fluidized bed reaction by the carrier gas Device 2, the mixed gas velocity of the reaction gas and the carrier gas is 75mL / min; the dysprosium source and the reaction gas are simultaneously fed into the flui...

Embodiment 2

[0065] This embodiment provides a preparation method of dysprosium oxide-coated AlNiCo magnetic material composite powder, the preparation method provided in the present invention such as figure 1 Carried out in the system device shown, described preparation method comprises the following steps:

[0066] (1) Pass argon gas into the fluidized bed reaction device as a protective gas, so that the alnico particles with a particle size of 1 to 3 μm are in a fluidized state in the protective atmosphere;

[0067] (2) the dysprosium source DyCl 3 After preheating to 900°C, the carrier gas is sent to the fluidized bed reaction device 2, and the mixed gas velocity of the dysprosium source and the carrier gas is 80mL / min; the reaction gas is preheated to 50°C and sent to the fluidized bed reaction by the carrier gas Device 2, the mixed gas velocity of reaction gas and carrier gas is 120mL / min; Dysprosium source and reaction gas are synchronously fed into fluidized bed reaction device 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com