Rate cycling improved lithium iron phosphate battery and preparation method thereof

A lithium iron phosphate battery and rate technology, applied in the direction of batteries, battery electrodes, battery pack components, etc., can solve the problems of low specific capacity, poor cycle performance, poor safety performance, etc., to improve adhesion, prevent internal Short circuit, the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a rate cycle-improved lithium iron phosphate battery, characterized in that: the positive electrode is prepared: LiFePO 4: Super-P:KS-6:CNTs:PVDF:NMP=87:2:3:3:5:144. Dissolve PVDF in NMP first, stir for 3 hours, then mix the lithium iron phosphate material and the conductive agent, and use a dry powder mixer to disperse and stir evenly. The stirring speed is 24r / min, and the stirring time is 120min. Then add the mixed materials into the glue solution, stir at high speed for 4 hours to disperse, the low speed revolution speed is 20r / min, the high speed dispersion speed is 2200r / min, and the vacuum degree is -0.09MPa. The stirred slurry is sieved and coated on aluminum foil after vacuum defoaming, and then dried, rolled, and cut to obtain positive electrode sheets. The material of the tab is aluminum strip, the width is 6 mm, and the number of tabs is 3;

[0033] Preparation of negative electrode: CAG-3:Super-P:VGCF:CMC:SBR:H 2 O=91.5:2:2:1.7:2.8:...

Embodiment 1

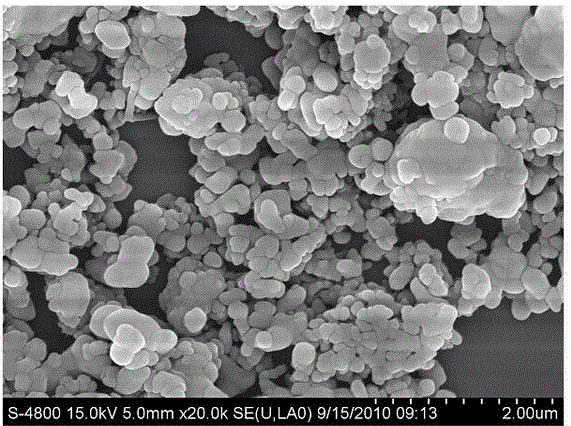

[0040] The present invention is described below by taking the preparation process of a 26650-2300mAh-3.3V high-rate battery as an example. The positive electrode material used in the battery is as follows: figure 1 As shown, the specific preparation method of the battery is as follows:

[0041] Preparation of positive electrode: LiFePO 4: Super-P:KS-6:CNTS:PVDF:NMP=87:2:3:3:5:144. Dissolve PVDF in NMP first, stir for 3 hours, then mix the lithium iron phosphate material and the conductive agent, and use a dry powder mixer to disperse and stir evenly. The stirring speed is 24r / min, and the stirring time is 120min. Then add the mixed materials into the glue solution, stir at high speed for 4 hours to disperse, the low speed revolution speed is 20r / min, the high speed dispersion speed is 2200r / min, and the vacuum degree is -0.09MPa. The stirred slurry is sieved and coated on carbon-coated aluminum foil after vacuum defoaming, and then dried, rolled, and cut to make positive ele...

Embodiment 2

[0045] Preparation of positive electrode: LiFePO 4: Super-P:KS-6:CNTS:PVDF:NMP=87:2:3:3:5:144. Dissolve PVDF in NMP first, stir for 3 hours, then mix the lithium iron phosphate material and the conductive agent, and use a dry powder mixer to disperse and stir evenly. The stirring speed is 24r / min, and the stirring time is 120min. then mix well

[0046] Add the materials into the glue solution, stir at high speed for 4 hours to disperse, the low speed revolution speed is 20r / min, the high speed dispersion speed is 2200r / min, and the vacuum degree is -0.09MPa. The stirred slurry is sieved and coated on aluminum foil after vacuum defoaming, and then dried, rolled, and cut to make positive electrode sheets. The material of the tabs is aluminum strip, the width is 6mm, and the number of tabs is 3. The shape of the pole piece is as figure 2 shown.

[0047] Preparation of negative electrode: CAG-3:Super-P:CNTC:CMC:SBR:H 2 O=91.5:2:2:1.7:2.8:133. Dissolve CMC in water first, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com