Preparation of Ag2MoO4-CuMoO4 composite antibacterial powder by virtue of ultrasound co-precipitation and ultrasound-molten salt methods

A technology of ag2moo4-cumoo4, AM1-CM1, applied in the field of synthesizing Ag2MoO4-CuMoO4 composite antibacterial powder by ultrasonic-molten salt method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

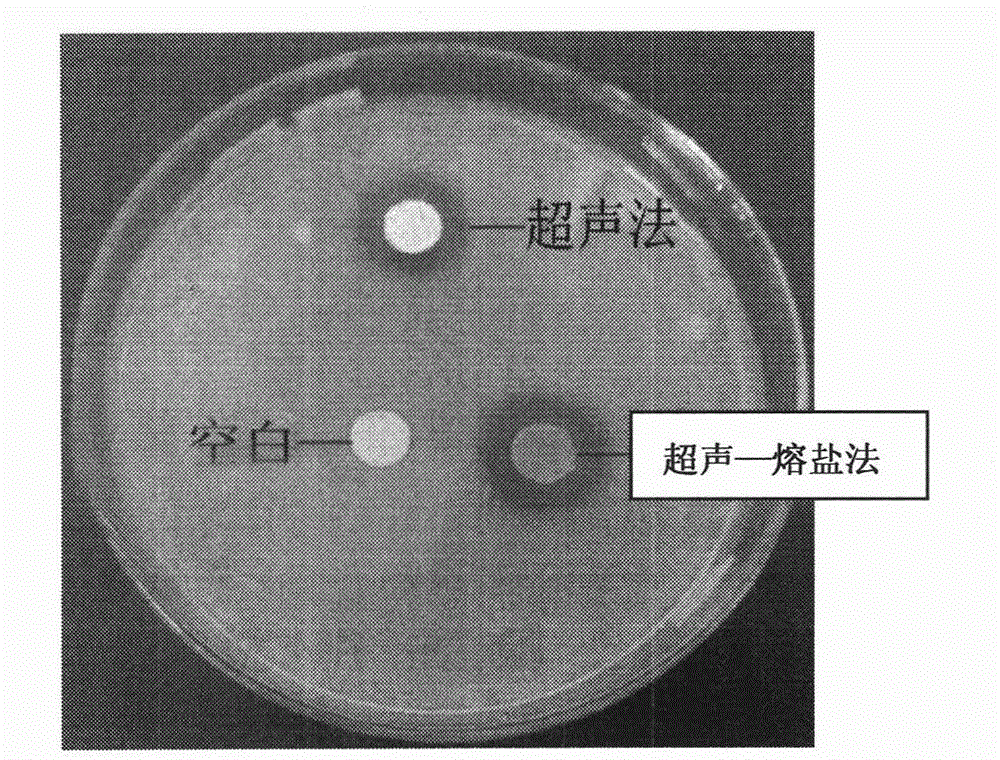

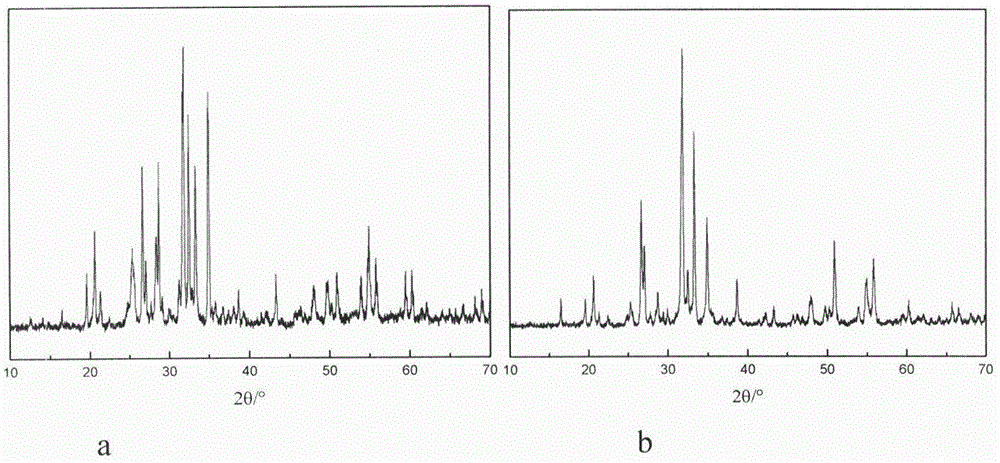

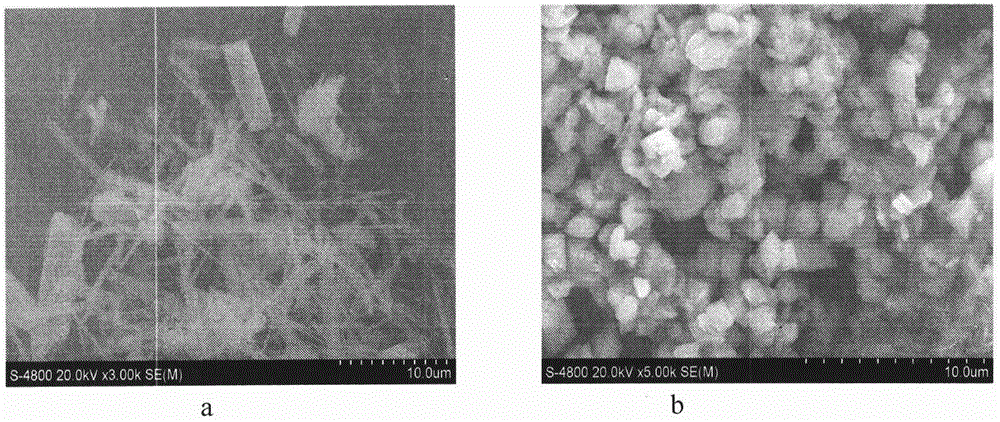

[0027] Preparation of Ag2MoO4-CuMoO4 powder or AM1-CM1 by ultrasonic co-precipitation method:

[0028] The concentration of Ag is 0.3mol / L 2 (NO 3 ) 2 And Cu(NO 3 ) 2 The aqueous solution was slowly added dropwise to 0.3mol / L Na 2 MoO 4 In the aqueous solution, make Cu(NO 3 ) 2 With Ag 2 (NO 3 ) 2 The molar ratio is 1:1-4; a total of 80ml mixed solution is configured; react for 30 minutes under ultrasonic conditions, and the temperature is controlled at 30°C, so that the mixed solution is fully mixed and the chemical co-precipitation reaction is completed. After mixing, there is fluorescence in the mixed solution Yellow precipitate is formed; the mixed solution is separated by centrifugal separation and the remaining precipitate is filtered, and then the precipitate is washed with distilled water and absolute ethanol, and dried at a temperature of 80 ℃ for 12 hours to obtain fluorescent green Ag2MoO4-CuMoO4 antibacterial powder, namely AM1-CM1.

Embodiment 2

[0030] Preparation of Ag by Ultrasonic-Molten Salt Method 2 MoO 4 -CuMoO 4 The powder is AM2-CM2:

[0031] Mix AM1-CM1 with composite molten salt (the mass ratio of NaNO3 to LiNO3 is 1:1, etc.) at a mass ratio of 1:3-14, and add an appropriate amount of absolute ethanol to grind for 1-3h in a mortar to make AM1-CM1 Mix well with molten salt as the reaction medium. The mixture was put into a crucible, dried at 90°C for 3 hours, put into an electric furnace, calcined at 340°C, and kept for 4 hours. After cooling, a solidified product was obtained. Fully soak and wash the solidified product with distilled water, then centrifuge and wash with distilled water to remove the remaining molten salt, and after drying, the earthy brown Ag can be obtained 2 MoO 4 -CuMoO 4 Powder, namely AM2-CM2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com