Super capacitor charcoal electrode material, super capacitor charcoal electrode, preparation method of material, and preparation method of electrode

A technology of supercapacitor and carbon electrode, applied in the direction of hybrid capacitor electrode, etc., can solve the problem of large consumption, achieve the effect of high specific capacity, excellent high current performance, and improve high current rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is used to illustrate the preparation method of the carbon electrode material provided by the present invention and the preparation method of the carbon electrode for supercapacitor.

[0052] Preparation of aromatics from coal liquefaction:

[0053] Weigh 50g coal direct liquefaction residue, mix with 150g coal direct liquefaction medium oil (distillation range 220-260°C) at 250°C and stir at 300r / min for 45min to extract coal liquefaction aromatics. The composition and properties of coal direct liquefaction residue and coal liquefaction aromatics are shown in Table 1.

[0054] Table 1

[0055]

carbon content

hydrogen content

average molecular weight

Ash content

Softening Point

Coal direct liquefaction residue

64.75% by weight

3.36% by weight

——

26.15% by weight

130℃

Coal liquefied aromatics

91.2% by weight

5.65% by weight

360

2800ppm

150℃

[0056] Preparation ...

Embodiment 2

[0066] This embodiment is used to illustrate the preparation method of the carbon electrode material provided by the present invention and the preparation method of the carbon electrode for supercapacitor.

[0067] Preparation of aromatics from coal liquefaction:

[0068] Same as Example 1.

[0069] Preparation of carbon electrode materials:

[0070] 1) Heating 66g of coal liquefied aromatics to 250°C and stirring for 1 hour under air atmosphere for stabilization;

[0071] 2) Carbonize the stabilized sample (softening point: 240°C) at 400°C for 1 hour under the protection of high-purity nitrogen;

[0072] 3) Mix the product obtained by carbonization with KOH at a weight ratio of 1:2 and activate at 650°C for 1 hour;

[0073] 4) The alkali was removed by acid washing with HCl with a volume ratio of 3:1, washed with deionized water to neutrality and dried to obtain the carbon electrode material for supercapacitors.

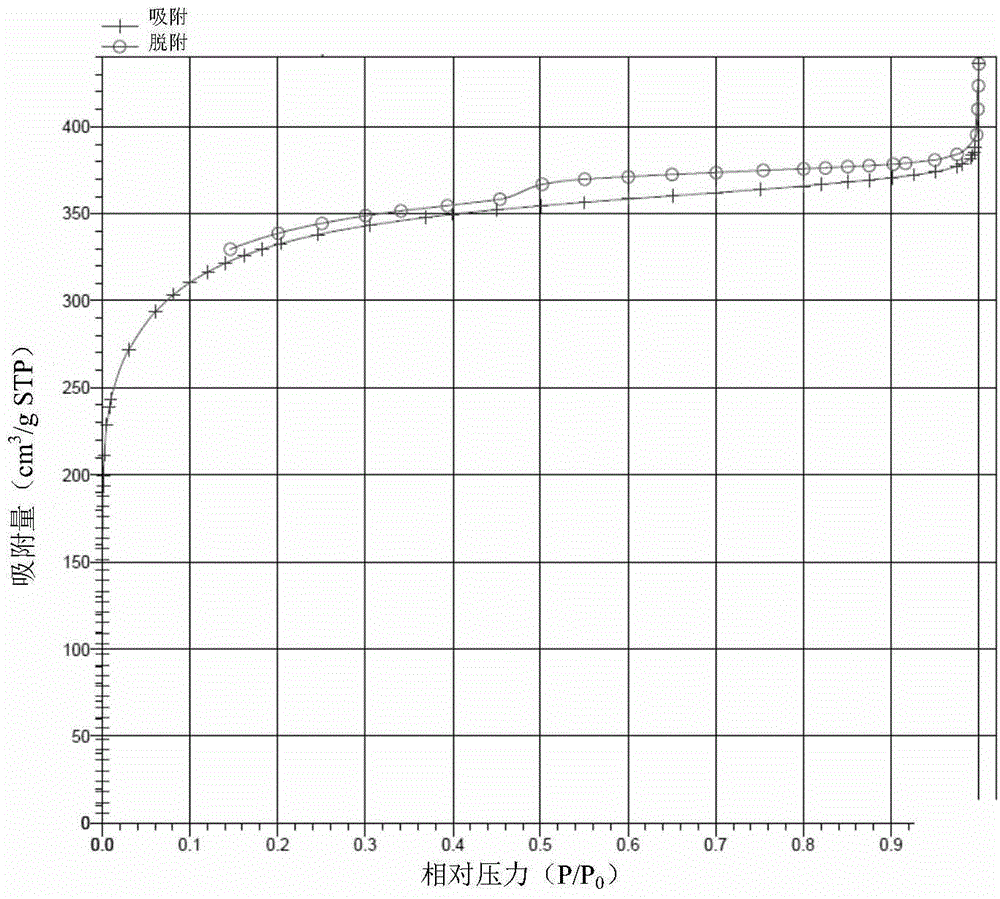

[0074] The carbon electrode material has a specific surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com