A kind of method for producing rubber extended oil base oil from medium and low temperature coal tar

A low-temperature coal tar and rubber extension oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of inability to stabilize resources of rubber extension oil, poor quality, and reduced output, and achieve rubber miscibility Excellent oxidation stability, low product viscosity drop, and low ring-opening activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

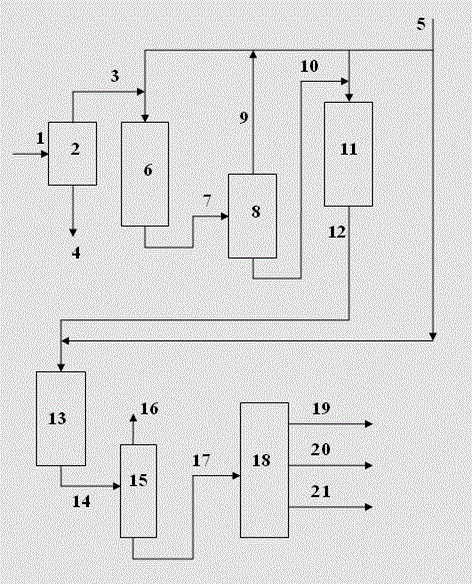

Method used

Image

Examples

preparation example Construction

[0033] The preparation process of the hydrogenation modification catalyst of the present invention comprises: after uniformly mixing the amorphous silica-alumina and the modified Y zeolite, adding a binder, kneading, rolling into agglomerates, extruding on an extruder to obtain a carrier, Reload the hydrogenation active metal.

[0034] The preparation method of amorphous silicon aluminum used comprises the steps:

[0035] a. Prepare sodium aluminate solution and sodium silicate solution;

[0036] b. Add the sodium aluminate solution and the sodium silicate solution into the gel forming tank concurrently, and ventilate and feed CO at the same time 2 gas, adjust sodium aluminate solution, sodium silicate solution and CO 2 Flow rate, control the pH value of the material in the gel tank to 9-11, control the neutralization reaction temperature to 20-50°C, and the neutralization reaction time to 0.5-1.5 hours;

[0037] c. Under the controlled temperature and pH value of step b, t...

Embodiment 1

[0054] Prepare 700 solid sodium aluminate to a concentration of 200gAl 2 o 3 / L concentrated sodium aluminate solution, then diluted to a concentration of 35gAl 2 o 3 / L sodium aluminate working solution (a), take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 150gSiO 2 / L sodium silicate working solution 2L (b). Take a 30L steel plastic tank, open the container valves containing (a) and (b) respectively, and ventilate and feed CO with a concentration of 45v% at the same time 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 1 hour, and quickly adjust the CO 2 flow rate, keep the pH of the system at about 10.0, and the reaction temperature is 30°C. After the reaction of (a) and (b) is completed, stop feeding CO 2 , and then the ventilation was stable for 40 minutes, and the slurry was filtered and washed with 85°C deionized water until neutral. Dry at 120°C for 8 hours, crush and sieve to obtain amorphous silica-alumina GL. ...

Embodiment 2

[0056] Get 80g silicon aluminum GL, 30g modified Y zeolite (SiO 2 / Al 2 o 3 40, unit cell constant 2.432nm, infrared acidity 0.19mmol / g specific surface 866m 2 / g, pore volume 0.52ml / g) and 250g adhesive made by peptizing nitric acid and SB alumina, kneading, rolling, making extrudable paste, extruding into strips. Carrier A was obtained by drying at 110°C for 6 hours and calcining at 550°C for 4 hours. Then 80 g of A was impregnated with 200 ml of a Mo-Mi co-impregnation solution in excess for 2 hours, dried at 110° C. for 6 hours, and calcined at 500° C. for 4 hours to obtain hydrogenation upgrading catalyst A. The physical properties of the hydrogenation upgrading catalyst are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com