Method for alloying Ga element through neodymium-iron-boron permanent magnet material

A permanent magnet material, NdFeB technology, applied in the field of alloying Ga element of NdFeB permanent magnet material, can solve the problems of large burning loss of Ga element, troublesome operation, low utilization rate, etc., to improve utilization rate, reduce The effect of volatilization and reduction of burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

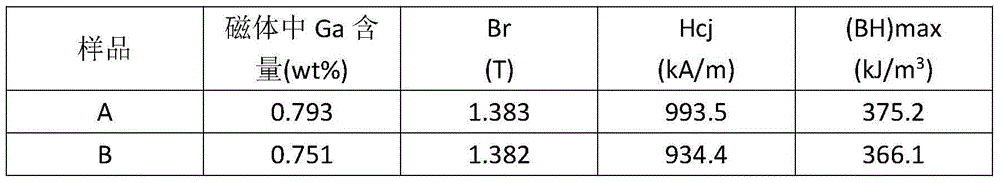

Embodiment 1

[0021] According to the composition of Nd29.8Fe68.41Ga0.8B0.99 (weight percent), the alloying element Ga is added in the form of Fe-Ga alloy, that is, 29.8kg of metal Nd, 5.5kg of B-Fe alloy (containing 18wt% B), 4kg of Fe-Ga alloy (containing 20wt% Ga), 60.7kg of commercially pure Fe are batched together, and 3% (percentage by weight) of rare earth Nd is considered in addition, and all raw materials are prepared through the scale ingot process to prepare neodymium with a thickness of about 300 μm Iron-boron-based quick-setting flakes were prepared by hydrogen breaking and jet milling to prepare 2:14:1 NdFeB-based powders with an average particle size of 3.5 μm. The powders were oriented and pressed in a 1.8T magnetic field and pressed isostatically. The obtained The compact is placed in a vacuum sintering furnace, vacuum sintered at 1080°C for 3 hours, and then subjected to secondary tempering (primary tempering: 920°C / 3h, secondary tempering: 500°C / 2h), and finally sintered N...

Embodiment 2

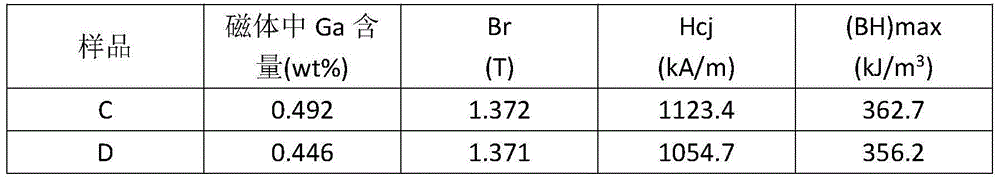

[0027] According to the composition of Nd29Dy1.5Fe68.01Ga0.5B0.99 (weight percent), the alloying element Ga is added in the form of Fe-Ga alloy, that is, the B-Fe alloy of 29kg of metal Nd, 1.5kg of metal Dy, and 5.5kg of B-Fe alloy (containing 18wt% B), 2kg of Fe-Ga alloy (containing 25wt% Ga), and 62kg of industrial pure Fe are batched together, and 3% (percentage by weight) of rare earth Nd is considered in addition, and all raw materials are prepared through a scale ingot process with a thickness of about The 300μm NdFeB-based quick-setting flakes are prepared by hydrogen breaking and jet milling to prepare 2:14:1 NdFeB-based powders with an average particle size of 3.5μm. The powder is oriented and pressed in a 1.8T magnetic field and isostatically pressed , put the obtained compact into a vacuum sintering furnace, sinter in vacuum at 1080°C for 3h, and then perform secondary tempering (primary tempering: 920°C / 3h, secondary tempering: 500°C / 2h), and finally get sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com