Maximally tilted fiber bragg grating SPR (Surface Plasmon Resonance) biochemical sensor and manufacture method thereof

A biochemical sensor, tilted fiber grating technology, used in instruments, scientific instruments, material analysis by optical means, etc., to achieve high refractive index sensitivity, high signal-to-noise ratio and high Q value, and not easy to electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

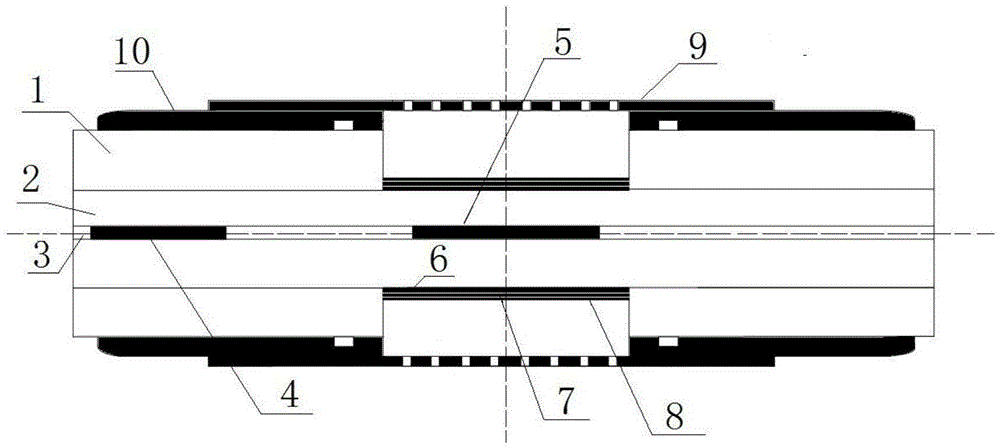

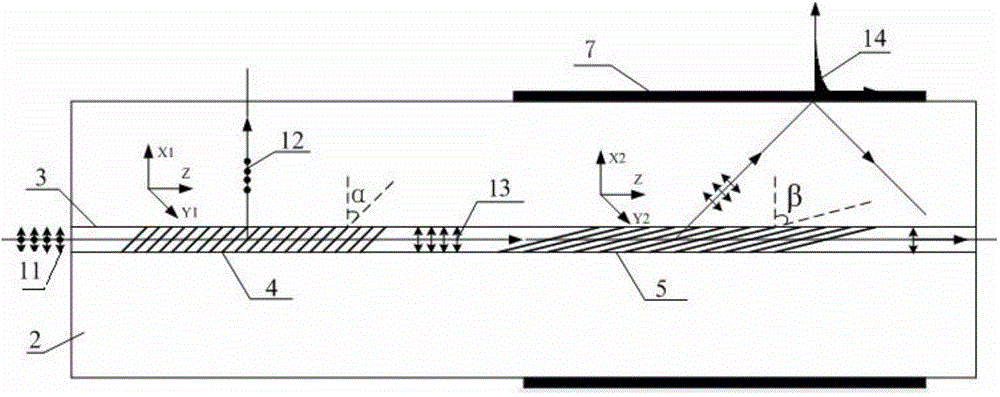

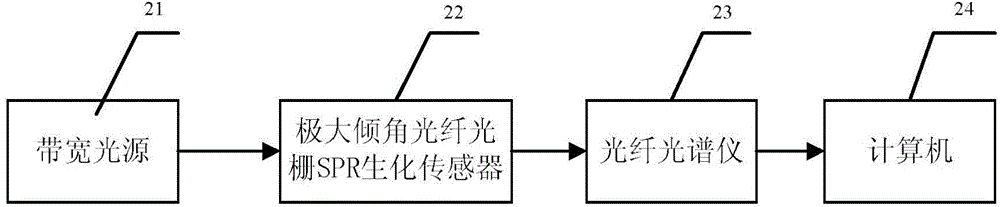

[0032] see Figure 1 to Figure 6 , a very large angle fiber grating SPR biochemical sensor, including an optical fiber core 3 and an optical fiber cladding 2 wrapping the optical fiber core 3; As a polarizer of a fiber grating SPR biochemical sensor with a very large tilt angle; the angle α between the tilted grating stripes of the first tilted fiber grating 4 and the longitudinal axis of the optical fiber is 45°; the middle section of the optical fiber core 3 is provided with a second tilted optical fiber Grating 5, the second tilted fiber grating 5 is used as an optical resonant coupler between the fiber core 3 and the fiber cladding 2; the angle β between the tilted grating stripes of the second tilted fiber grating 5 and the longitudinal axis of the fiber is 79° to 84° °; the fast axis X of the first tilted fiber grating 4 1 and slow axis Y 1 Respectively with the fast axis X of the second tilted fiber grating 5 2 and slow axis Y 2 Parallel; the outer surface of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com