Method for determining zirconium content in silicon-zirconium alloy

A silicon-zirconium alloy and determination method technology, applied in the field of chemical analysis and test, can solve the problems of many reagent consumption, complicated operation, long time required, etc., and achieve the effects of reducing the amount of reagents, reducing the degree of pollution, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

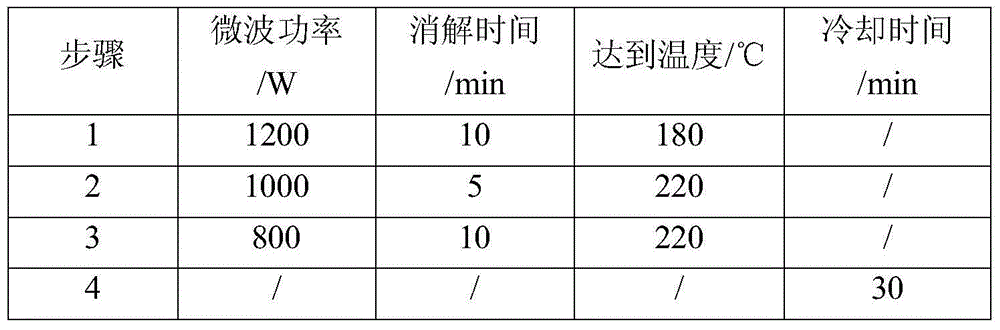

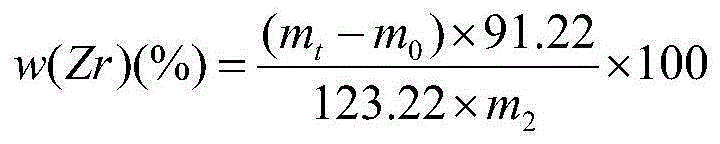

Method used

Image

Examples

specific example 1

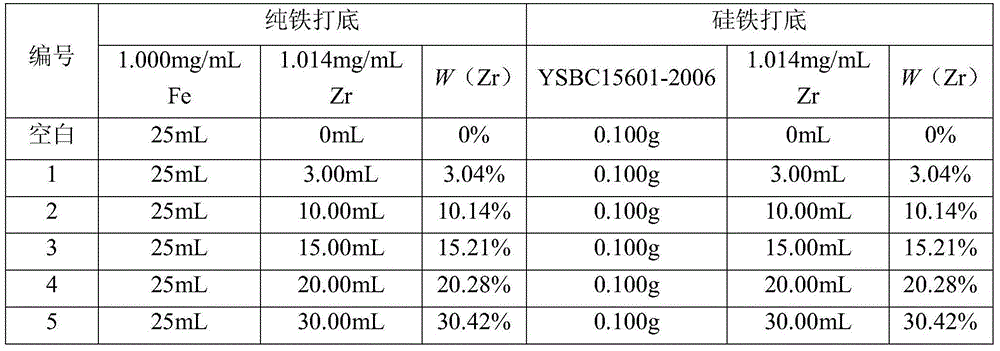

[0024] Drawing of calibration curve with pure iron base:

[0025] Weigh 0.2500g of high-purity iron into a 250mL polytetrafluoroethylene beaker, add 40mL of nitric acid (1+1), drop about 10mL of hydrofluoric acid, heat slightly until completely dissolved, transfer to a 250mL plastic volumetric flask after cooling, and dilute with water To the mark, mix well, the solution is 1.000mg / mL; when in use, pipette 25.00mL into six 250mL plastic volumetric flasks as a base, and add different volumes of zirconium standard solutions, see Table 1.

[0026] The drawing of the calibration curve based on ferrosilicon:

[0027] Select a ferrosilicon standard substance with a similar iron content to silicon-zirconium alloy, weigh 6 parts of 0.1000g and place them in a 250mL polytetrafluoroethylene beaker, add 20mL nitric acid (1+1), and drop about 5mL hydrofluoric acid, After adding 5mL of perchloric acid to fume, add an appropriate amount of hydrochloric acid, heat to dissolve the salts, tra...

specific example 2

[0036] Drawing of calibration curve with pure iron base:

[0037] Weigh 0.2500g of high-purity iron into a 250mL polytetrafluoroethylene beaker, add 40mL of nitric acid (1+1), drop about 10mL of HF, slightly heat until completely dissolved, transfer to a 250mL plastic volumetric flask after cooling, and dilute to the mark with water. Mix well, the solution is 1.000mg / mL; when in use, pipette 25.00mL into six 250mL plastic volumetric flasks as a base, and add different volumes of zirconium standard solutions, see Table 1.

[0038] The drawing of the calibration curve based on ferrosilicon:

[0039] Select a ferrosilicon standard substance with a similar iron content to silicon-zirconium alloy, weigh 6 parts of 0.1000g and place them in a 250mL polytetrafluoroethylene beaker, add 20mL nitric acid (1+1), and drop about 5mL hydrofluoric acid, After adding 5mL of perchloric acid to fume, add an appropriate amount of hydrochloric acid, heat to dissolve the salts, transfer to a 250m...

specific example 3

[0045] Drawing of calibration curve with pure iron base:

[0046] Weigh 0.2500g of high-purity iron into a 250mL polytetrafluoroethylene beaker, add 40mL of nitric acid (1+1), drop about 10mL of HF, slightly heat until completely dissolved, transfer to a 250mL plastic volumetric flask after cooling, and dilute to the mark with water. Mix well, the solution is 1.000mg / mL; when in use, pipette 25.00mL into six 250mL plastic volumetric flasks as a base, and add different volumes of zirconium standard solutions, see Table 1.

[0047] The drawing of the calibration curve based on ferrosilicon:

[0048] Select a ferrosilicon standard substance with a similar iron content to silicon-zirconium alloy, weigh 6 parts of 0.1000g and place them in a 250mL polytetrafluoroethylene beaker, add 20mL nitric acid (1+1), and drop about 5mL hydrofluoric acid, After adding 5mL of perchloric acid to fume, add an appropriate amount of hydrochloric acid, heat to dissolve the salts, transfer to a 250m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com