Processing method of deep etching smooth surface based on SiC substrate slice

A technology of smooth surface and processing technology, which is applied in the field of processing technology of wide bandgap semiconductor based on SiC substrate sheet deep etching smooth surface, can solve the problem that SiC is difficult to obtain smooth surface, etc., and achieve simple preparation method, controllable conditions and operation process concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

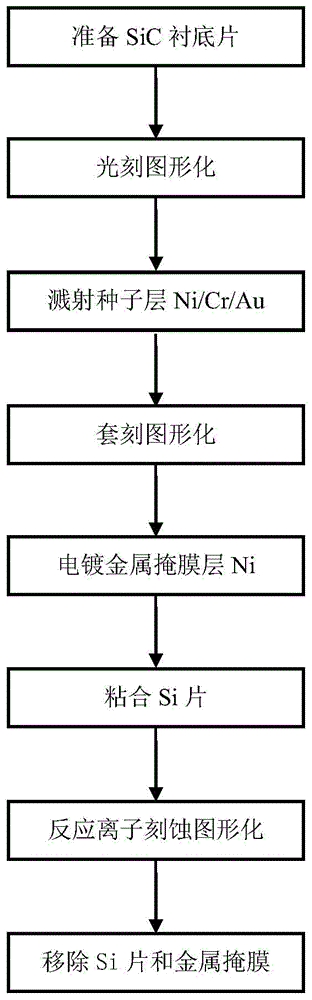

[0008] The present invention is based on the processing technology of deep etching smooth surface of SiC substrate (such as figure 1 shown), including the following steps:

[0009] Step 1, prepare the SiC substrate sheet: the substrate SiC substrate sheet is an ingot grown by the PVT method, which is oriented, cut, double-sided polished, and double-sided CMP polished to obtain a 3-inch industrial wafer, which is cut into 3×2cm 2 The substrates are cleaned by semiconductor RCA process.

[0010] Step 2, photolithographic patterning: place the substrate on a rubber drying table at 100°C for drying, and evenly spin-coat a 1 μm thick photoresist on the substrate through a coater, and place it on the rubber drying table for 5 minutes Pre-baking, then patterning it with a UV lithography machine, and hardening the film for 10 minutes after development.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com