Electrolyte capable of preventing spinel lithium titanate-based lithium ion secondary battery from being swollen

An anti-lithium titanate, electrolyte technology, applied in secondary batteries, electrical components, circuits, etc., can solve the problems of battery gas production, no SEI film protection, easy to catalyze electrolyte reduction, etc. Excellent performance, good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

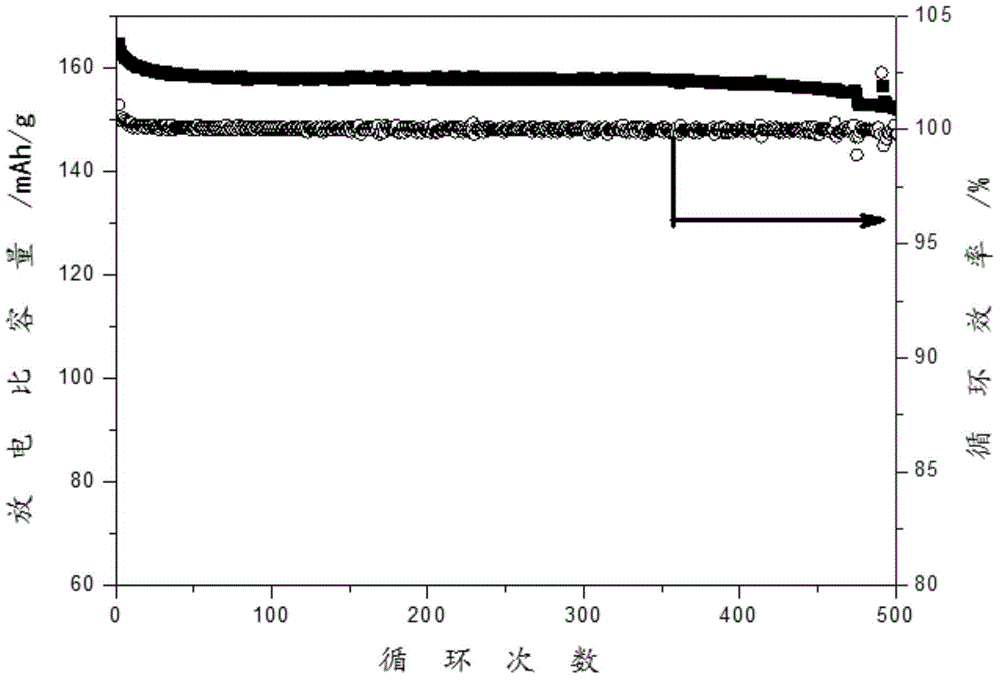

Embodiment 1

[0031] LiPF 6 Dissolve LiDFOB and LiDFOB into electronic-grade organic solvents propylene carbonate (PC) and dimethyl carbonate (DMC) mixed solvents with water below 10ppm respectively, wherein each solvent is configured according to the mass ratio of 30 parts of PC and 70 parts of DMC. mixed solvent, and then add electrolyte salt to it to dissolve, in which LiPF 6 The concentration of LiDFOB is 1.0mol / L, and the concentration of LiDFOB is 0.1mol / L. After the lithium salt is completely dissolved, 0.5% of the total mass of the electrolyte is added as an additive.

[0032] Use the Mettler Karl Fischer C20 coulometric moisture tester to test the water content of the electrolyte ≤ 10ppm; use the acid-base titration method to titrate the acidity of the electrolyte ≤ 15ppm; use the Mettler conductivity meter FE30 to test the water content of the electrolyte at 25°C Conductivity, conductivity ≥ 10ms / cm; contact angle tester to test the wetting performance of the electrolyte. After ...

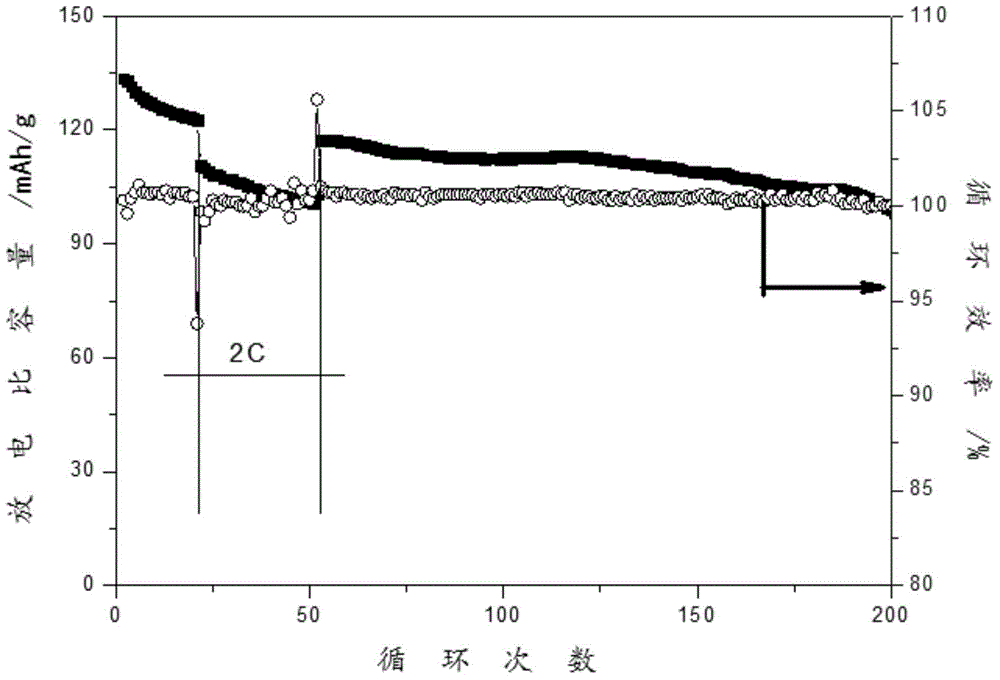

Embodiment 2

[0037] Mix 20 parts of sulfolane, 20 parts of PC and 60 parts of DMC evenly, after testing that the water content is less than 10ppm, refrigerate and add electrolyte salt LiPF 6 and LiDFOB, where LiPF 6 The concentration of LiDFOB is 1.0mol / L, the concentration of LiDFOB is 0.1mol / L, and then 2% of the additive nicotinamide is added thereto.

[0038] The production and testing of the battery are the same as in Example 1.

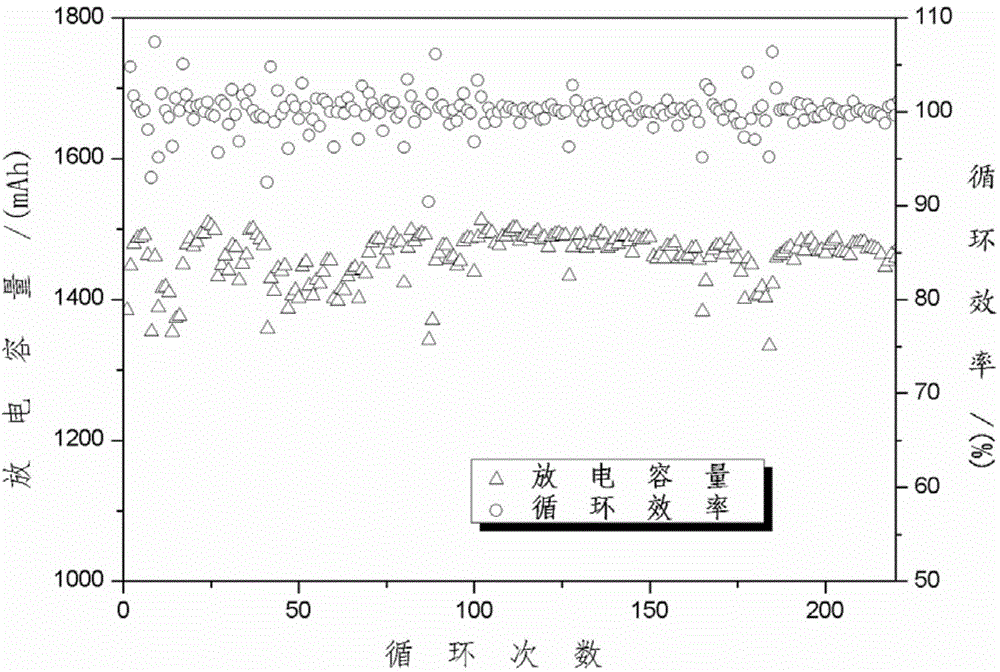

Embodiment 3

[0040] Mix 20 parts of sulfolane, 40 parts of PC and 40 parts of DMC evenly, after the water content is less than 10ppm, refrigerate and add electrolyte salt LiPF 6 , LiTFSI and LiBOB, where LiPF 6 The concentration of LiTFSI is 0.8mol / L, the concentration of LiTFSI is 0.2mol / L, the concentration of LiBOB is 0.1mol / L, and 1.2% of additive 3-piperidine carboxamide is added.

[0041] The battery manufacturing and testing methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com