Whole-speed range control method of position sensor of elevator door motor

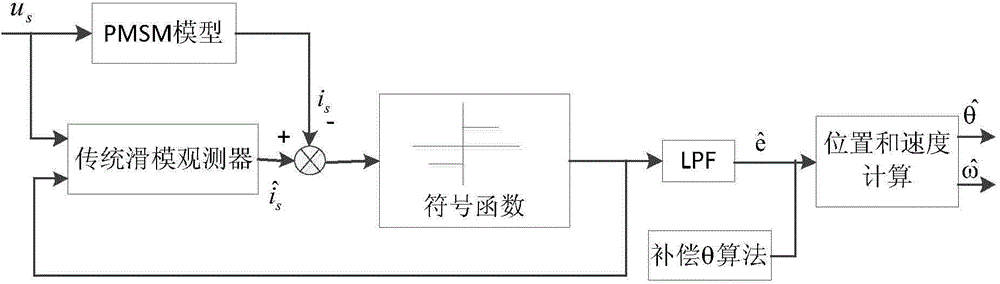

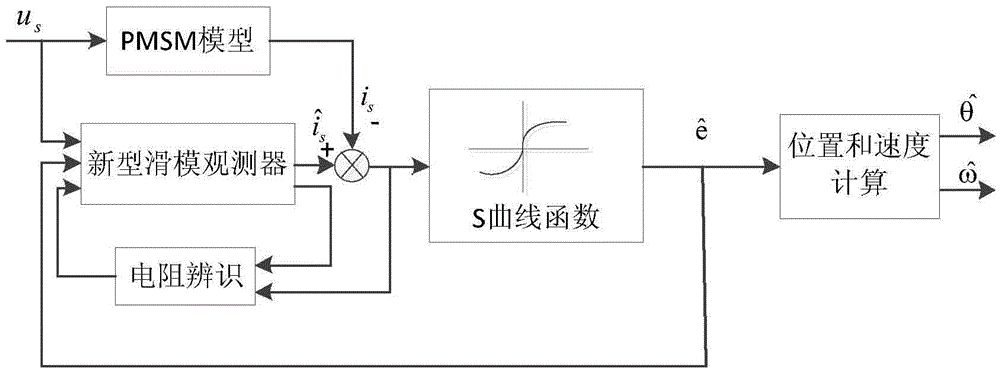

A control method and elevator door machine technology, applied in the field of motors, can solve problems such as system chattering and time delay, affecting detection accuracy, and complex algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

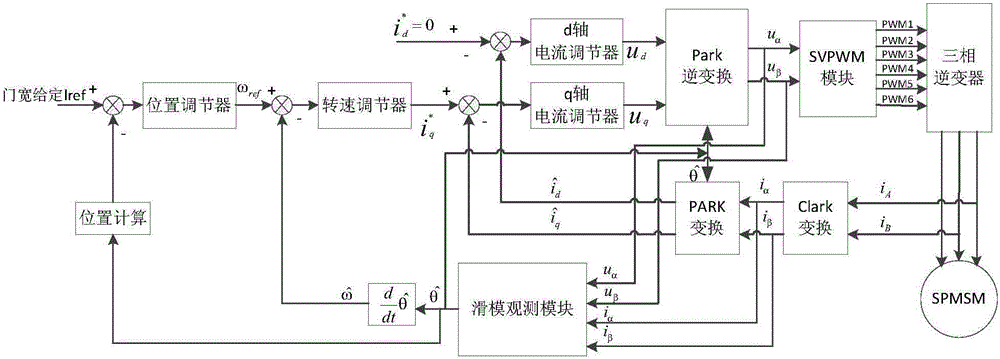

[0030] According to the motor given speed output by the position regulator, the sensorless control strategy of the full speed range of the door machine is divided into three stages: zero low speed range, transition switching range and medium and high speed range.

[0031] The zero low speed range control method is given by the d-axis current regulator The q-axis current regulator is given as the output of the speed controller, and the injection of high-frequency pulse vibration current to the door machine motor is completed through current closed-loop control;

[0032] Extract the output voltage signal of the current regulator and multiply it by the cosω of the same frequency h The t signal is modulated, and then the signal f related to the rotor position error is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com