Application of peel powder of citrus plants as filler in food processing

A technology of powder and citrus, which is applied in the direction of food processing, the function and application of food ingredients, etc., can solve the problems of restricting the application and development of citrus peel food, and achieve the effects of simple preparation method, environmental protection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

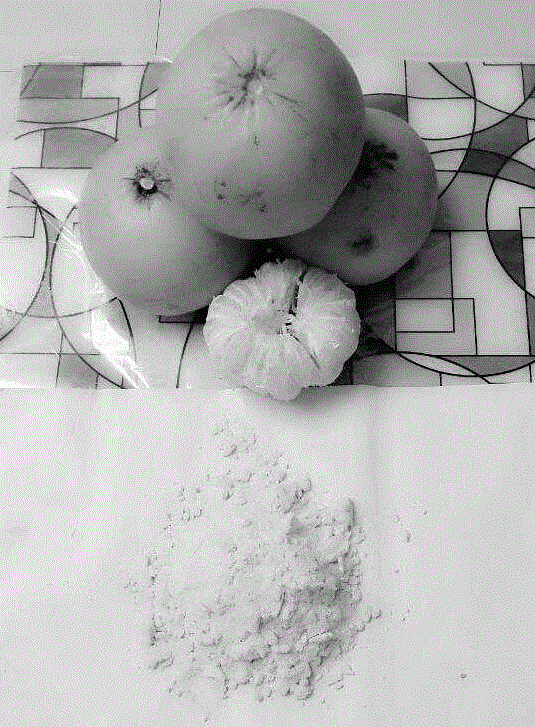

[0046] Embodiment 1 The preparation of pomelo peel powder A

[0047] Taking grapefruit peel as an example, the preparation of grapefruit peel powder is described. The existing debittering methods of pomelo peel mainly include: (1) treatment with low concentration solution of salt, acid and sugar; (2) treatment with specific glycosidase. For example, methods disclosed in patents with application numbers 201210098630.8, 201010260741.5, and 201210493374.2, or methods reported in patents with application numbers 200910180073.2, 201110270456.6, and 200810156414.8. In this example, only the method of debittering by immersion in hypertonic solution is described in detail.

[0048] The pomelo fruit is taken, the skin of the pomelo fruit is cleaned, and the spongy peel is left as a raw material. Choose plump, shiny, richly scented and unspoiled sleeve leather as the base material. Cut the selected pomelo peel into small pieces, such as 3-5cm long, 1-1.5cm wide, and 2-3mm thick.

[...

Embodiment 2

[0059] The preparation of embodiment 2 pomelo peel powder B

[0060] Grapefruit peel B refers to removing the green part of the grapefruit peel, and only retaining the spongy (white floc) as the raw material. The spongy substance is pulverized by a freeze-drying pulverization method, and passed through an 80-mesh sieve after pulverization.

[0061] In addition, we set up a parallel group, put the spongy substance in a 60°C oven to fully dry it, and then crush it with an ordinary pulverizer, and the crushed result is an 80-mesh sieve.

[0062] For the two groups of methods, we all selected 1000g of spongy as the raw material, and weighed after pulverization. The actual yield before sieving by the freeze-drying pulverization method was 980g, and the actual yield of the oven-dried group was 620g. After sieving, the actual powder of the freeze-dried and crushed group was 920 g, and the actual powder of the oven-dried group was 510 g.

[0063] Put the powder under 100 oil immersi...

Embodiment 3

[0064] Example 3 Preparation of Soft Materials of Grapefruit Peel A and Grapefruit Peel B

[0065] Soft material refers to the "agglomerate" after the powder and binder are fully mixed and uniform. The amount of binder and wetting agent added is an important factor affecting the quality of soft material. If the viscosity of the soft material is too small, it will loosen when preparing biscuits, and a large amount of fine powder will be produced, resulting in a low yield. If the soft material is too viscous, it will affect the quality of biscuits. Appropriate adhesives can make the soft material realize the "light grip into a ball, and light pressure to disperse" in "pharmaceutics", which is the best state for preparing biscuits.

[0066] Table 1 Loss of several formulations

[0067]

[0068] Fully mix the components and water medium (according to the conventional method of those skilled in the art in the field of baking) with the ingredients in the formula in Table 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com