A contraceptive and antimicrobial dual-function vaginal compound temperature-sensitive hydrogel preparation and its preparation method

A temperature-sensitive hydrogel and microbe-killing technology, applied in the field of medicine and health, can solve the problems of large side effects, inconvenient use, etc., and achieve the effects of prolonging residence time, good spermicidal effect, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

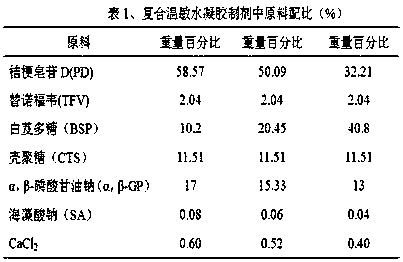

Embodiment 1

[0041] The preparation of microspheres comprises the following steps:

[0042] a. Preparation of raw material solution

[0043]Accurately weigh 5 g each of chitosan and bletilla striata polysaccharide, 1 g of tenofovir, which were vacuum-dried to constant weight at room temperature, and dissolve them in 1000 mL of 0.5% acetic acid solution;

[0044] b. Filtration, spray drying

[0045] After being filtered through a 0.45 μm microporous membrane, the filtrate was introduced into the double-flow spiral nozzle of a Büchi 290 small spray dryer through a peristaltic pump. The inlet temperature was controlled at 110 °C, the feed rate was 1.5 mL / min, and the air flow rate was 300 L / h, the mass ratio of chitosan / Bletilla striata polysaccharide / tenofovir is 5:5:1;

[0046] c. Preparation of microsphere powder

[0047] Spray drying "one-step" to prepare PD / TFV / CTS / BSP microsphere powder, collect the microsphere powder in a desiccator for later use.

Embodiment 2

[0049] The preparation of microspheres comprises the following steps:

[0050] a. Preparation of raw material solution

[0051] Accurately weigh 5 g of chitosan, 10 g of Bletilla striata polysaccharide, and 1 g of tenofovir that were vacuum-dried to constant weight at room temperature, and dissolve them in 1000 mL of 0.5% acetic acid solution;

[0052] b. Filtration, spray drying

[0053] After being filtered through a 0.45 μm microporous membrane, the filtrate was introduced into the double-flow spiral nozzle of the Büchi 290 small spray dryer through a peristaltic pump. The inlet temperature was controlled at 110°C, the feed rate was 4 mL / min, and the air flow rate was 400 L / h , the mass ratio of chitosan / Bletilla striata polysaccharide / tenofovir is 5:10:1;

[0054] c. Preparation of microsphere powder

[0055] Spray drying "one-step" to prepare PD / TFV / CTS / BSP microsphere powder, collect the microsphere powder in a desiccator for later use.

Embodiment 3

[0057] The preparation of microspheres comprises the following steps:

[0058] a. Preparation of raw material solution

[0059] Accurately weigh 5 g of chitosan, 20 g of Bletilla striata polysaccharide, and 1 g of tenofovir that were vacuum-dried to constant weight at room temperature, and dissolve them in 1000 mL of 0.5% acetic acid solution.

[0060] b. Filtration, spray drying

[0061] After being filtered through a 0.45 μm microporous membrane, the filtrate was introduced into the double-flow spiral nozzle of the Büchi 290 small spray dryer through a peristaltic pump. The inlet temperature was controlled at 110°C, the feed rate was 6.5 mL / min, and the air flow rate was 500 L / h , the mass ratio of chitosan / Bletilla striata polysaccharide / tenofovir is 5:20:1;

[0062] c. Preparation of microsphere powder

[0063] Spray drying "one-step" to prepare PD / TFV / CTS / BSP microsphere powder, collect the microsphere powder in a desiccator for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com