Preparation method for rod-like CuO-ZnO composite oxide catalyst

A composite oxide and catalyst technology, applied in the preparation of organic compounds, preparation of hydroxyl compounds, physical/chemical process catalysts, etc., to achieve the effect of simple operation, good catalytic effect, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

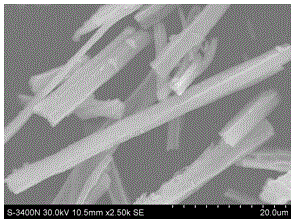

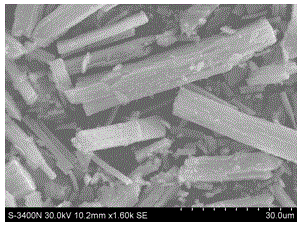

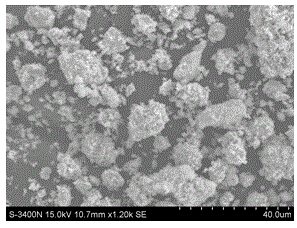

Image

Examples

Embodiment 1

[0026] A method for preparing a rod-shaped CuO-ZnO composite oxide catalyst, that is, using glycine as a chelating agent to first synthesize a copper-zinc composite glycine chelate crystal, and then roasting the crystal to obtain a copper-zinc composite oxide catalyst. The preparation process specifically includes the following steps :

[0027] (1), solution preparation

[0028] Take by weighing 5.00g copper acetate, 0.56g zinc acetate joins in 80ml deionized water, obtain the mixed aqueous solution of copper acetate, zinc acetate, copper in the mixed aqueous solution of copper acetate, zinc acetate: the mol ratio of zinc is 9:1;

[0029] Weigh 2.30g glycine and dissolve it in 10ml deionized water to obtain a glycine aqueous solution with a concentration of 3mol / L;

[0030] Weighing 5.56g of polyethylene glycol with a molecular weight of 200 was dissolved in 10ml of water to obtain an aqueous solution of polyethylene glycol with a mass percent concentration of 35.7%;

[0031...

Embodiment 2

[0036] A method for preparing a rod-shaped CuO-ZnO composite oxide catalyst, that is, using glycine as a chelating agent to first synthesize a copper-zinc composite glycine chelate crystal, and then roasting the crystal to obtain a copper-zinc composite oxide catalyst. The preparation process specifically includes the following steps :

[0037] (1), solution preparation

[0038] Take by weighing 5.00g copper acetate, 0.72g zinc acetate joins in 80ml deionized water, obtain the mixed aqueous solution of copper acetate, zinc acetate, copper in the mixed aqueous solution of copper acetate, zinc acetate: the mol ratio of zinc is 7:1;

[0039] Weigh 2.36g glycine and dissolve in 10ml deionized water to obtain a glycine aqueous solution with a concentration of 3.1mol / L;

[0040] Weighing 5.72g of polyethylene glycol with a molecular weight of 4000 was dissolved in 10ml of water to obtain an aqueous solution of polyethylene glycol with a molecular weight of 36.3% at a molecular weig...

Embodiment 3

[0047] A method for preparing a rod-shaped CuO-ZnO composite oxide catalyst, that is, using glycine as a chelating agent to first synthesize a copper-zinc composite glycine chelate crystal, and then roasting the crystal to obtain a copper-zinc composite oxide catalyst. The preparation process specifically includes the following steps :

[0048] (1), solution preparation

[0049] Take by weighing 5.00g copper acetate, 1.00g zinc acetate joins in 80ml deionized water, obtain the mixed aqueous solution of copper acetate, zinc acetate, copper in the mixed aqueous solution of copper acetate, zinc acetate: the mol ratio of zinc is 5:1;

[0050] Weigh 2.48g glycine and dissolve it in 10ml deionized water to obtain a glycine aqueous solution with a concentration of 3.3mol / L;

[0051] Weighing 6.00g of polyethylene glycol with a molecular weight of 10,000 was dissolved in 10ml of water to obtain an aqueous solution of polyethylene glycol with a molecular weight of 37.5% at a molecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com