A kind of vertical graphene nanoribbon, preparation and application in the preparation of supercapacitor

A graphene nanoribbon and single-walled carbon nanotube technology, applied in the field of carbon nanomaterial preparation, achieves the effects of loose requirements, simplified process and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

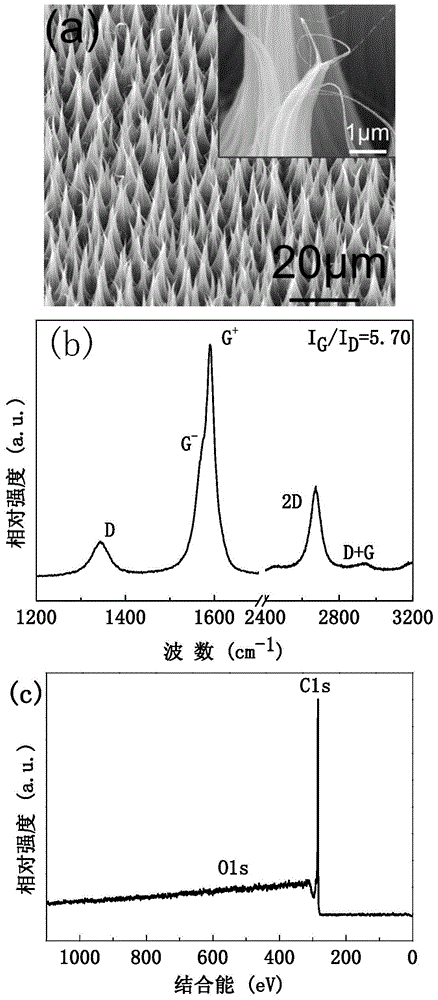

[0039] Embodiment 1: The CVD furnace used in the present invention is a hot wire-CVD furnace.

[0040] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. Evaporate 10nm Al sequentially by E-Beam Evaporator 2 o 3 , 0.8nm Fe.

[0041] (2) Set the furnace temperature to 700°C and the gas flow rates to H 2 :200sccm, C 2 h 2 : 1.8 sccm, H through deionized water 2 It is 200sccm, and the total air pressure is 25Torr. The heating wire is a single tungsten wire with a power of 30W. Place the silicon wafer prepared in (1) at 0.4 in front of the tungsten wire, set the power of the tungsten wire to 0 after 30 seconds of reaction, adjust the total air pressure to 6.4 Torr, and complete the vertical array growth of single-walled carbon nanotubes after 15 minutes of reaction.

[0042] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C, and the gas flow to H 2 :200sccm, CH ...

Embodiment 2

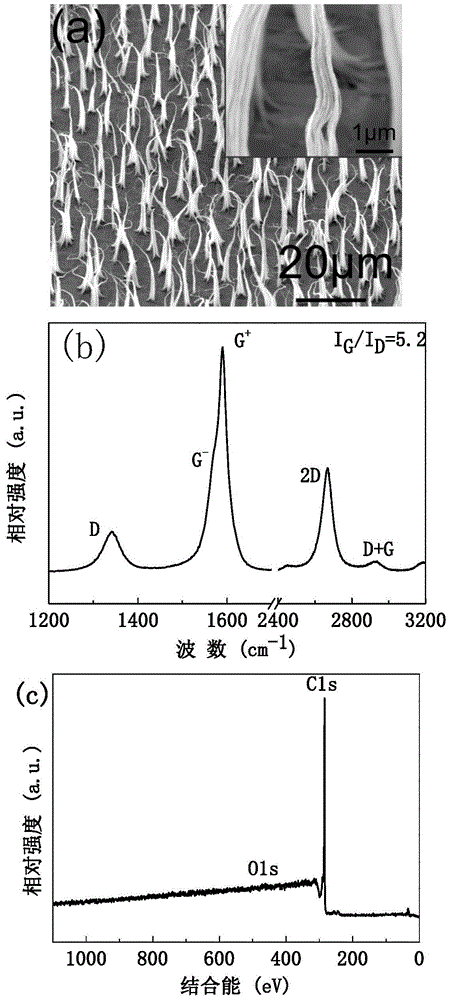

[0044] Embodiment 2: The CVD furnace used in the present invention is a hot wire-CVD furnace.

[0045] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. Evaporate 11nm Al sequentially by E-Beam Evaporator 2 o 3 , 1nm Fe.

[0046] (2) Set the furnace temperature to 750°C and the gas flow rates to H 2 :210sccm, C 2 h 2 : 2.5 sccm, H through deionized water 2 It is 200sccm, and the total air pressure is 25Torr. The heating wire is a single tungsten wire with a power of 35W. Place the silicon wafer prepared in (1) 0.3 cm in front of the tungsten wire, set the power of the tungsten wire to 0 after 30 s of reaction, adjust the total air pressure to 6.4 Torr, and complete the vertical array growth of single-walled carbon nanotubes after 15 min of reaction.

[0047] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C, and the gas flow to H 2 :200sccm, CH 4 : 0.1 scc...

Embodiment 3

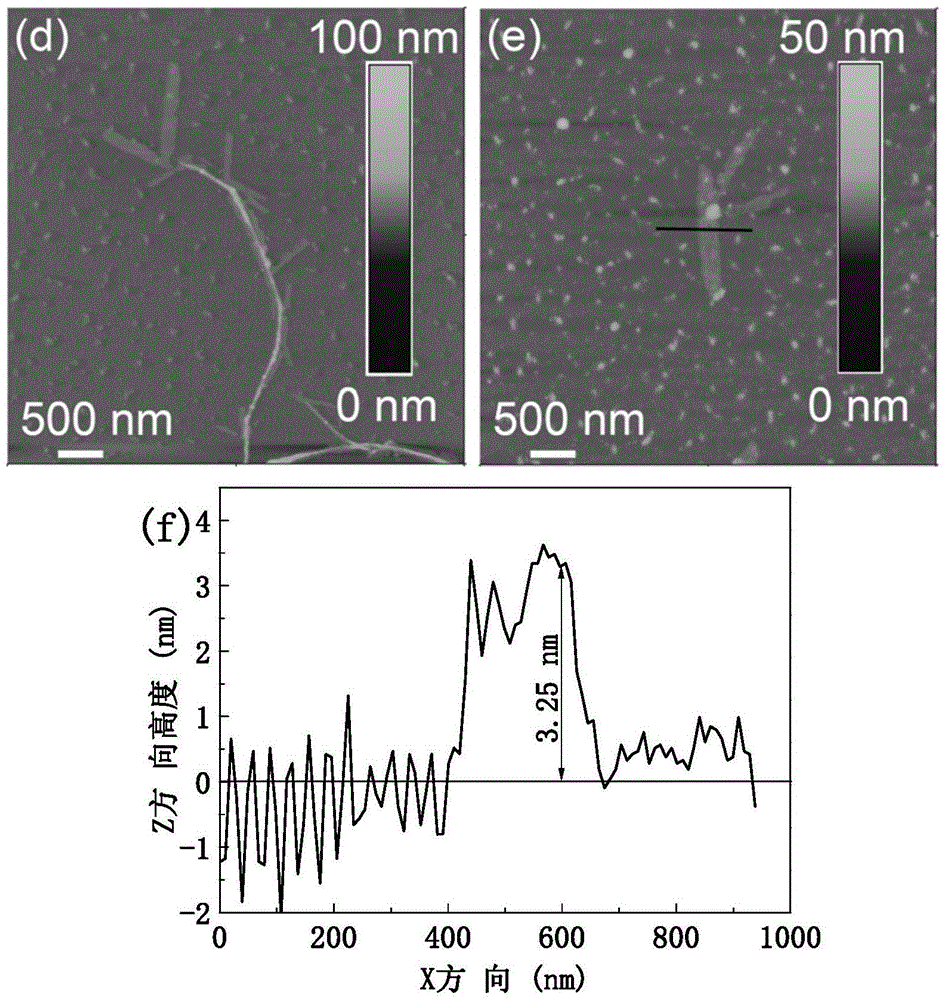

[0049] Embodiment 3: The CVD furnace used in the present invention is a hot wire-CVD furnace.

[0050] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. Evaporate 10nm Al sequentially by E-Beam Evaporator 2 o 3 , 1.2nm Fe.

[0051] (2) Set the furnace temperature to 760°C and the gas flow rates to H 2 :210sccm, C 2 h 2 : 2.2 sccm, H through deionized water 2 It is 200sccm, and the total air pressure is 25Torr. The heating wire is a single tungsten wire with a power of 35W. Place the silicon wafer prepared in (1) 0.3 cm in front of the tungsten wire, set the power of the tungsten wire to 0 after 30 s of reaction, adjust the total air pressure to 6.4 Torr, and complete the vertical array growth of single-walled carbon nanotubes after 15 min of reaction.

[0052] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C, and the gas flow to H 2 :210sccm, CH 4 : 0.5 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com