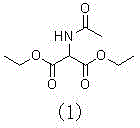

Preparation method of diethyl acetamidomalonate

A technology of diethyl acetamidomalonate and diethyl nitrosomalonate, applied in the field of medicinal chemistry, can solve the problems of high sodium acetate content, achieve high product content, low environmental pollution, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of diethyl nitrosomalonate: Add 500g of chloroform, 140g of diethyl malonate, and 90g of sodium nitrite into a 1000ml four-necked flask, stir, cool down to 0°C, and Add 105g of acetic acid dropwise, heat up to 40-45°C after the dropwise addition, and keep stirring for 15 hours. After the reaction, filter out the sodium acetate generated by the reaction, rinse the filter cake with 200g of chloroform, combine the filtrates, concentrate and evaporate under reduced pressure organic solvent to obtain light yellow oil, which was directly used in the next reaction.

Embodiment 2

[0023] Preparation of diethyl acetamidomalonate: Take the diethyl nitrosomalonate obtained in the previous step, 178 g of acetic anhydride, and 525 g of acetic acid were successively added to a 1000 ml four-neck flask, slowly added 115 g of zinc powder under stirring, and added When zinc powder is used, the temperature of the feed liquid is controlled at 40-50°C. After the addition, the feed liquid is kept at 50-60°C for 2 hours. After the reaction, the zinc acetate produced by the reaction is filtered off while it is hot, and the filter cake is washed twice with 100g of hot acetic acid. , combine the filtrates, concentrate under reduced pressure to recover acetic acid, when a white solid precipitates out, the concentration is over, add 500g of purified water, heat to reflux, cool down to 0°C and stir for 10 hours after the solid dissolves, filter, wash with 100g of purified water, 60°C Vacuum drying gave 156 g of white crystalline powder with a yield of 82.1%. HPLC area norma...

Embodiment 3

[0025] Preparation of diethyl nitrosomalonate: Add 500g of dichloromethane, 140g of diethyl malonate, and 120g of sodium nitrite into a 1000ml four-neck flask, stir, cool down to 0°C, and Add 131g of acetic acid dropwise, heat up to 35-40°C after the dropwise addition, and keep stirring for 12 hours. After the reaction, filter out the sodium acetate generated by the reaction, rinse the filter cake with 200g of dichloromethane, combine the filtrates, concentrate and evaporate under reduced pressure organic solvent to obtain light yellow oil, which was directly used in the next reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com