DOPO derivative and preparation method thereof

A technology of derivatives and oxides, which is applied in the field of organic synthesis, can solve the problems of polymer material application popularization restrictions, high-temperature deformation of polymer materials, and flammability, and achieve the effects of avoiding harsh preparation conditions, mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

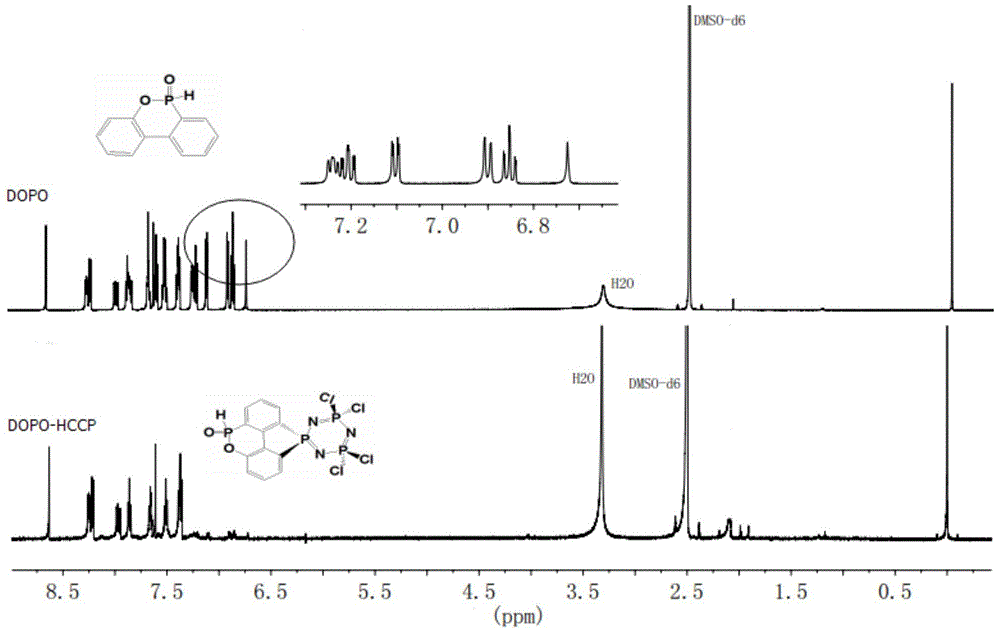

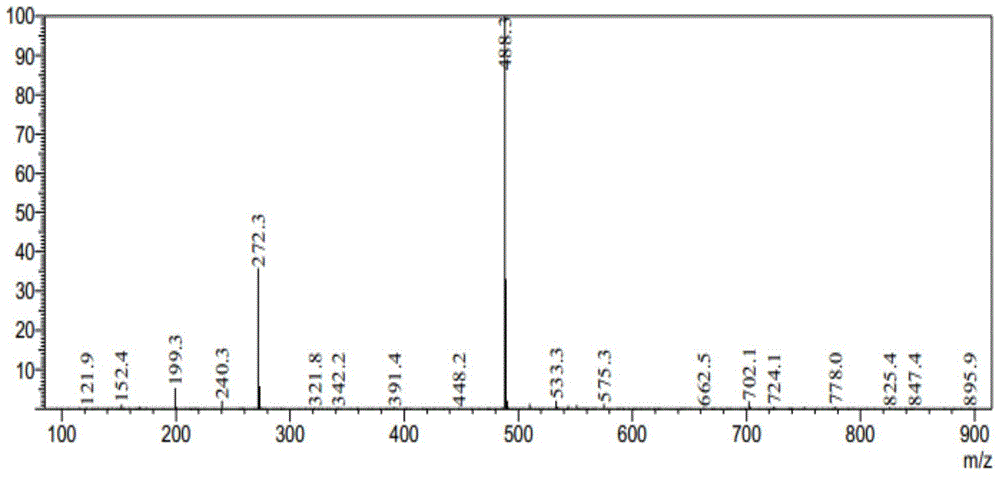

[0015] Specific embodiment 1: The structural formula of DOPO derivatives in this embodiment is

[0016] Its preparation method is carried out according to the following steps:

[0017] Step 1. Mix 10mmol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), 1mmol anhydrous potassium carbonate, and 10mmol hexachlorocyclotrimeric phosphazene (HCCP), Add 50mL of N,N-dimethylformamide, then stir at room temperature (25°C) until the substrate DOPO disappears (monitored by TLC) to stop the reaction;

[0018] Step 2, then poured into saturated brine and stirred, extracted three times with 50 mL of dichloromethane, combined the extracts and dried with anhydrous magnesium sulfate for 12 hours, concentrated to dryness with a rotary evaporator to obtain a light yellow solid, and then recrystallized with ethyl acetate , to obtain DOPO derivatives (DOPO-HCCP).

[0019] The reaction equation of the present embodiment is:

[0020]

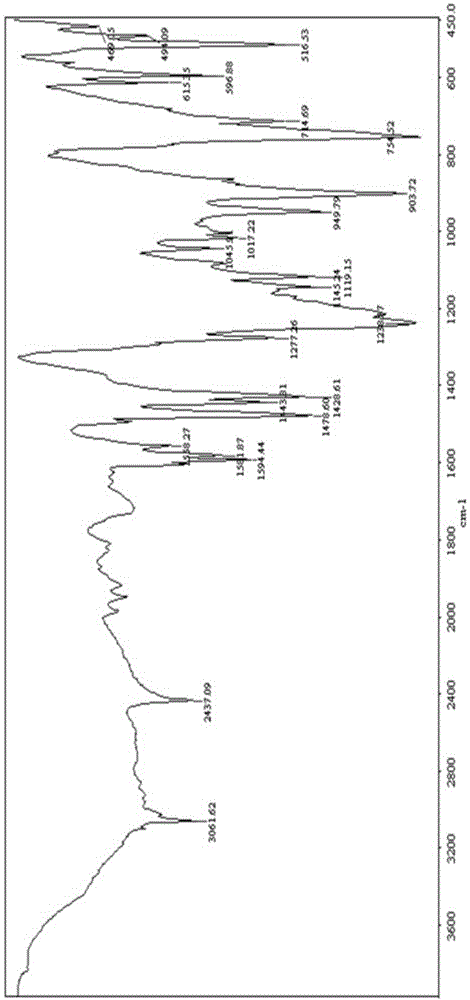

[0021] The DOPO derivative obtained in this em...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: adopt triethylamine to replace anhydrous potassium carbonate. Other steps and parameters are the same as in the first embodiment.

[0024] The DOPO derivative obtained in this embodiment is a white solid with a spiro ring structure, the yield is 70%, and the maximum thermal decomposition temperature is 370°C.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is: Potassium tert-butoxide is used to replace anhydrous potassium carbonate. Other steps and parameters are the same as in the first embodiment.

[0026] The DOPO derivative obtained in this embodiment is a white solid with a spiro ring structure, the yield is 65%, and the maximum thermal decomposition temperature is 370°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com