A kind of preparation method of polysiloxane airgel

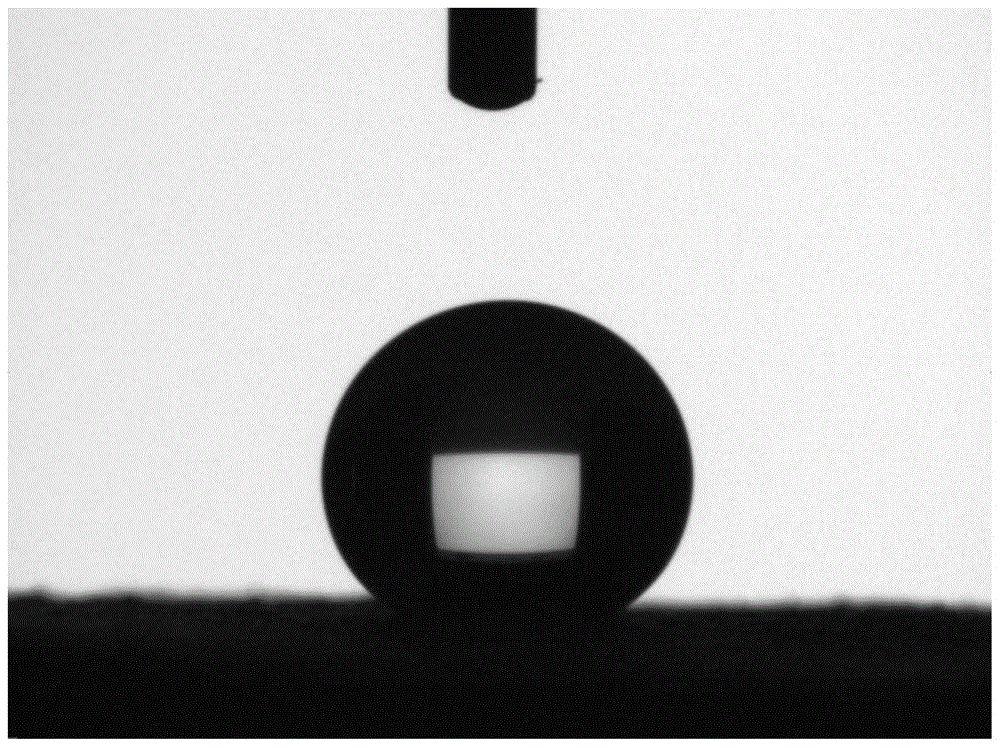

A polysiloxane and hydrogen polysiloxane technology is applied in the field of preparation of flexible and woven super-hydrophobic polysiloxane aerogels, and can solve the problems of cumbersome and time-consuming preparation steps of polysiloxane aerogels, poor environmental protection, Poor mechanical properties and other problems, to achieve the effect of easy industrial production, low production cost, simple and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of polysiloxane airgel

[0035] The preparation method of polysiloxane airgel comprises the steps:

[0036] The molecular weight of 1.80g is 1500-3000g / mol (average molecular weight is 1700g / mol) methylhydrogen polysiloxane (hydrogen content is 0.2wt%), 5.12g of molecular weight is 1500-3000g / mol (average Molecular weight is 2000g / mol) terminal vinyl dimethyl polysiloxane and Karstedt's catalyst (mass is 0.05% of the sum of methylhydrogen polysiloxane and terminal vinyl dimethyl polysiloxane mass) into a 50mL reactor, CO at 40°C 2 Fill to make the pressure of the system reach 16MPa, while CO 2 It is in a supercritical fluid state and releases CO after 4 hours of reaction 2 Obtain bulk airgel directly.

[0037] In this embodiment, the ratio of the number of moles of Si—H in the methyl hydrogen-containing polysiloxane to the number of moles of vinyl groups in the vinyl polysiloxane is 0.7:1.0.

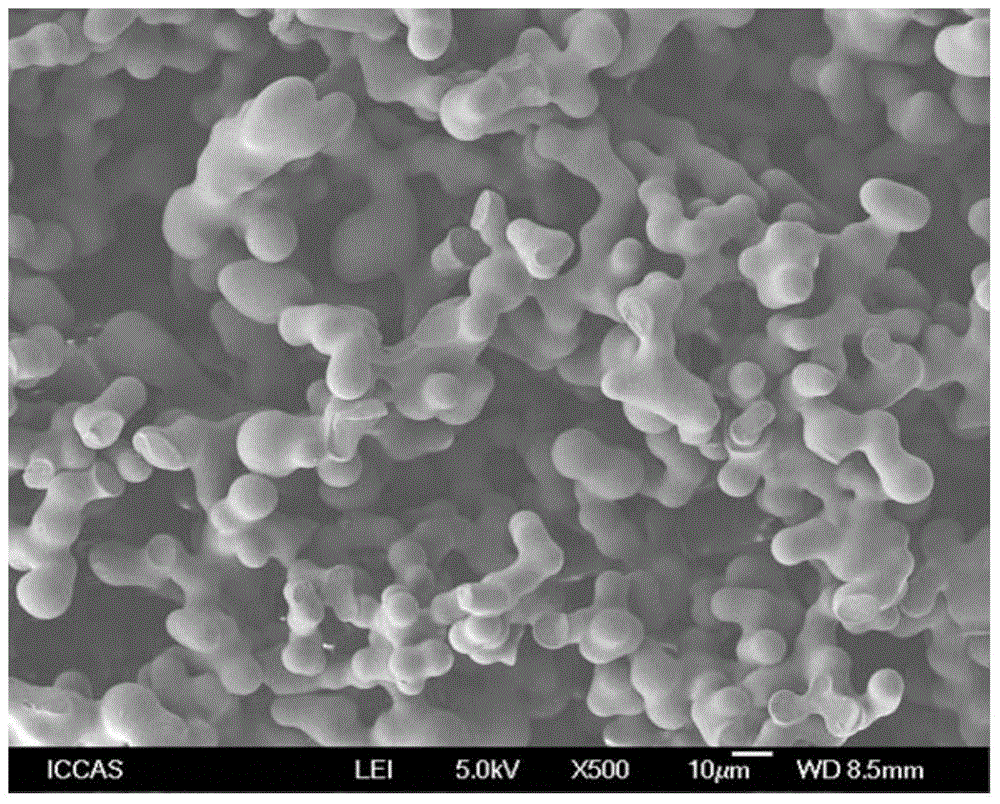

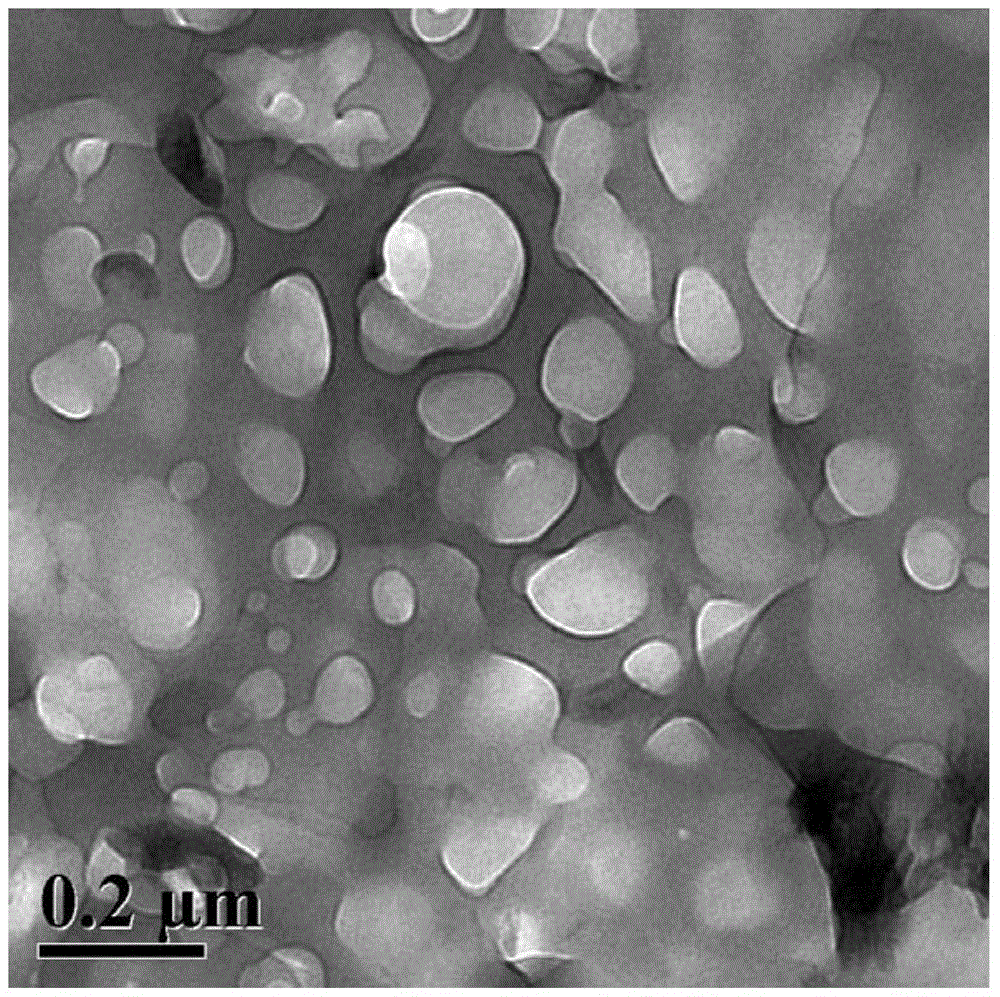

[0038] like figure 1 and figure 2Shown ...

Embodiment 2

[0039] Embodiment 2, the preparation of polysiloxane airgel

[0040] The preparation method of polysiloxane airgel comprises the steps:

[0041] 0.71g of methyl hydrogen polysiloxane (hydrogen content is 0.2wt%) with a molecular weight of 1500-3000g / mol (average molecular weight of 1700g / mol), 4.06g of a molecular weight of 5000-8000g / mol (average Molecular weight is 6000g / mol) terminal vinyl dimethyl polysiloxane and Karstedt's catalyst (mass is 0.05% of the sum of methylhydrogen polysiloxane and terminal vinyl dimethyl polysiloxane mass) In a 50mL reactor, CO at 40°C 2 Fill to make the pressure of the system reach 16MPa, while CO 2 It is in a supercritical fluid state and releases CO after 4 hours of reaction 2 Obtain bulk airgel directly.

[0042] In this embodiment, the ratio of the number of moles of Si—H in the methyl hydrogen-containing polysiloxane to the number of moles of vinyl groups in the vinyl polysiloxane is 1.0:1.0.

[0043] The scanning electron microscop...

Embodiment 3

[0044] Embodiment 3, the preparation of polysiloxane airgel

[0045] The preparation method of polysiloxane airgel comprises the steps:

[0046] 0.80 g of methyl hydrogen polysiloxane (with a hydrogen content of 0.2 wt%) with a molecular weight of 1500-3000 g / mol (average molecular weight of 1700 g / mol), 7.80 g of a molecular weight of 9000-13000 g / mol ( The average molecular weight is 10000g / mol) terminal vinyl dimethyl polysiloxane and Karstedt's catalyst (mass is 0.05% of the sum of methyl hydrogen polysiloxane and terminal vinyl dimethyl polysiloxane mass) into a 50mL reactor, CO at 40°C 2 Fill to make the pressure of the system reach 16MPa, while CO 2 In a supercritical state, release CO after 4 hours of heat preservation and pressure 2 Obtain bulk airgel directly.

[0047] In this embodiment, the ratio of the number of moles of Si—H in the methyl hydrogen-containing polysiloxane to the number of moles of vinyl groups in the vinyl polysiloxane is 1.0:1.0.

[0048] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com