Two-stage hydrotreating method of high dry point raw material

A technology of hydrotreating and high dry point, applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problems of reducing reaction speed, weak activity, shortening operation period, etc. , the effect of reducing the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

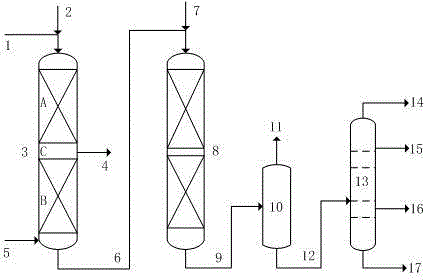

[0036] use figure 1 In the process flow shown, both the first-stage reaction zone and the second-stage reaction zone are filled with the hydrotreating catalyst B. In the second reaction zone, the upper part is a gas-liquid co-current process, and the lower part is a gas-liquid counter-current process. The catalyst loading volume ratio of the co-current reaction zone and the counter-current reaction zone is 1:1.

Embodiment 2

[0038] The basic process is the same as in Example 1. Only the catalyst A is loaded in the first stage reaction zone, and the catalyst B is loaded in the second stage reaction zone. In the second stage of the reaction zone, the catalyst loading volume ratio of the gas-liquid co-current and gas-liquid countercurrent reaction zones is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com